ኅዳር . 04, 2024 12:05 Back to list

Iron Powder Metallurgy Providers for Quality Manufacturing Solutions and Advanced Materials

The Rise of Iron Powder Metallurgy and Its Suppliers

In the world of manufacturing, iron powder metallurgy has emerged as a significant segment, driving innovation across various industries. As industries gravitate towards more sustainable and efficient processes, the demand for iron powder suppliers has soared. Understanding the intricacies of iron powder metallurgy and its suppliers is essential for both manufacturers and consumers.

What is Iron Powder Metallurgy?

Iron powder metallurgy is a process that involves the production of components from iron powders through techniques such as compacting and sintering. This method is known for its ability to produce high-precision parts with complex geometries while minimizing waste materials. The powder is compacted into a shape and then heated (sintered) to create a solid component. This technique is particularly beneficial for producing small and intricate products that are often required in industries like automotive, aerospace, and electronics.

Advantages of Iron Powder Metallurgy

1. Cost-Effectiveness One of the primary benefits is the cost-efficiency of the process. Traditional manufacturing methods, like machining, often result in significant waste, whereas powder metallurgy utilizes nearly every grain of material. This not only reduces costs but also minimizes environmental impact.

2. Design Flexibility Iron powder metallurgy allows for the production of components with complex geometries that might be difficult or impossible to achieve through traditional methods. This design flexibility enables engineers to create parts that are lighter, stronger, and more efficient in their intended applications.

3. Enhanced Material Properties The sintering process can enhance the mechanical properties of the components produced, such as improved hardness, tensile strength, and wear resistance. Furthermore, it allows for the incorporation of alloying elements that can enhance specific characteristics of the final product.

4. Sustainability As industries strive toward sustainable practices, iron powder metallurgy stands out. The process generates less waste, and the ability to recycle materials further enhances its eco-friendliness.

iron powder metallurgy supplier

The Role of Iron Powder Suppliers

With the increasing popularity and versatility of iron powder metallurgy, the role of suppliers has become crucial. Suppliers are responsible for providing high-quality iron powders that meet the stringent requirements of various manufacturing processes.

1. Quality Assurance The quality of iron powder directly impacts the final product's integrity. Suppliers must ensure consistency in particle size, shape, and purity. Advanced techniques are employed in production and testing to guarantee that the powders meet the specified industry standards.

2. Technical Expertise Suppliers often provide valuable technical support to manufacturers. This includes guidance on the selection of appropriate powders, processing parameters, and design optimizations. Their expertise is essential in navigating the complexities of powder metallurgy.

3. Customized Solutions Different applications may require specific properties from iron powders. Top suppliers are willing to collaborate with customers to develop customized powder solutions that match specific performance criteria. This adaptability is particularly important in specialized industries.

4. Sustainable Practices Leading iron powder suppliers are increasingly focusing on sustainable sourcing and production practices, responding to regulatory pressures and consumer demand for greener products. By adopting eco-friendly methods, they contribute to a more sustainable manufacturing landscape.

Conclusion

As the demand for more advanced and efficient manufacturing processes rises, iron powder metallurgy represents a promising avenue for innovation. The role of iron powder suppliers is critical in this paradigm, providing the materials necessary for high-quality production while ensuring sustainability through responsible practices. Manufacturers that leverage the benefits of iron powder metallurgy and collaborate closely with reliable suppliers will be well-positioned to meet the challenges of contemporary manufacturing while fostering economic and environmental sustainability. Investing in quality iron powders and establishing strong partnerships with reputable suppliers can lead to significant advancements in product performance and production efficiency.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

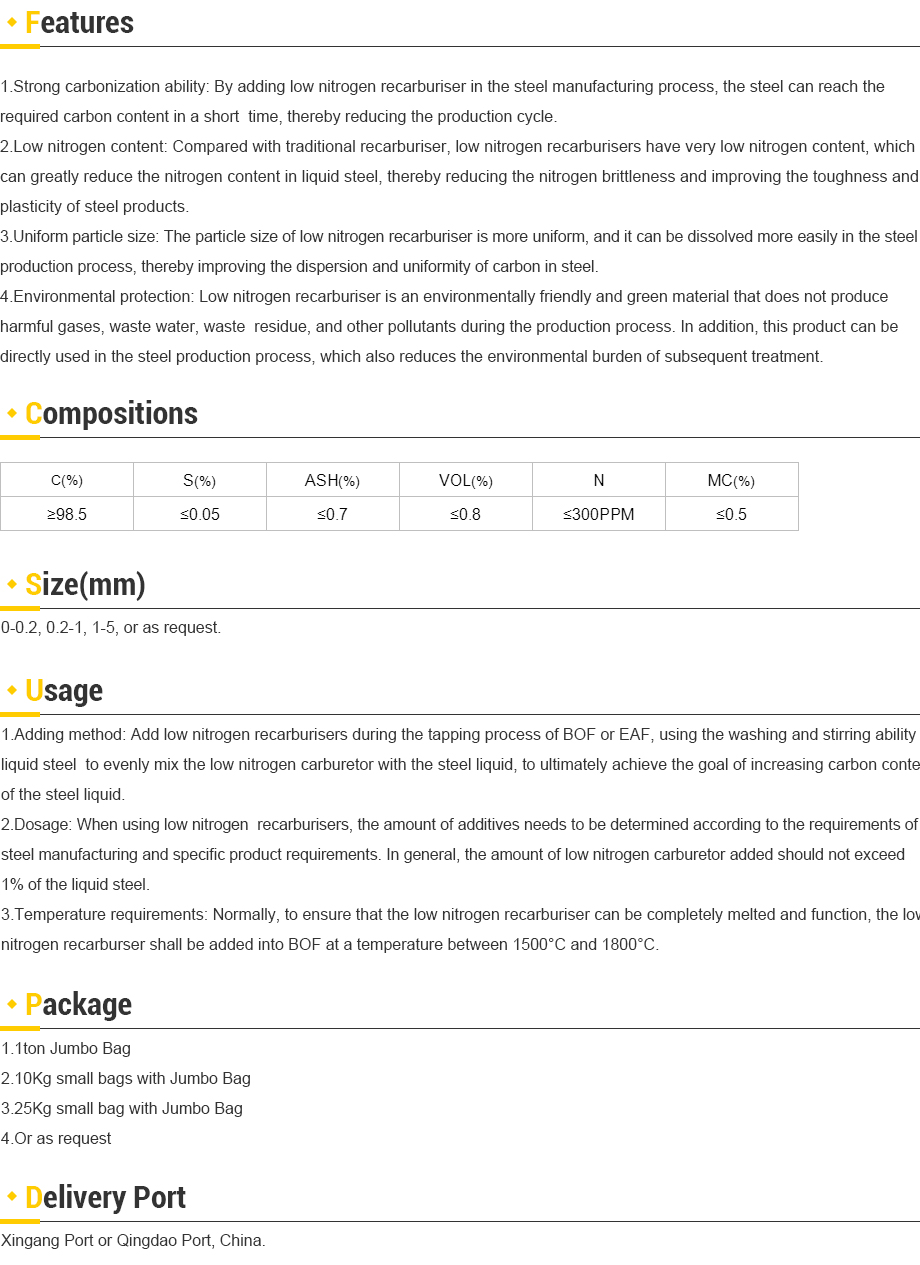

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025