ግንቦ . 31, 2025 01:19 Back to list

SWRCH15A Manufacturer High-Quality Cold Heading Wire Supplier

- Introducing the versatile capabilities of SWRCH15A cold heading steel wire rod

- Technical advantages and superior mechanical properties explained

- Global manufacturing landscape and key production regions

- Comparative analysis of leading SWRCH15A factories

- Customization options for specialized application requirements

- Industry-specific implementation success stories

- Strategic benefits of partnering with established SWRCH15A suppliers

(swrch15a)

Understanding SWRCH15A for Industrial Fastener Applications

SWRCH15A represents a cornerstone material in cold forging operations globally, with the fastener manufacturing sector consuming over 5.8 million metric tons annually. This low-carbon steel grade exhibits exceptional malleability under pressure, achieving deformation ratios exceeding 85% without fracture. As global infrastructure development accelerates, demand for SWRCH15A products has grown at a consistent 6.7% CAGR since 2020. The material's consistent performance stems from tightly controlled chemical composition: carbon content maintained at 0.13-0.18%, manganese at 0.30-0.60%, and phosphorus/sulfur impurities below 0.030%.

Technical Advantages and Material Specifications

Precision-engineered SWRCH15A delivers superior performance characteristics that justify its industrial dominance. The material achieves tensile strength between 440-570 MPa while maintaining elongation rates of 28-34%, enabling complex cold forging operations. Rigorous production protocols ensure hardness levels remain within 70-85 HRB, optimizing tooling longevity during high-volume manufacturing. Advanced continuous casting technology and controlled cooling processes produce consistent grain structure, reducing defect rates to under 0.3% across certified production batches.

Global Manufacturing Capabilities

Concentrated production hubs across Asia, Europe, and North America maintain global SWRCH15A supply chains. Japanese and Korean mills lead in precision manufacturing, leveraging robotic quality control systems that achieve dimensional tolerances within ±0.02mm. European facilities emphasize sustainable production, having reduced energy consumption by 18% through regenerative heating technology. Emerging manufacturing regions now contribute approximately 30% of global output, with Vietnam and India expanding capabilities through technology transfer partnerships.

Supplier Capability Analysis

| Manufacturer | Annual Capacity | Certifications | Material Testing | Lead Times |

|---|---|---|---|---|

| Precision Steelworks Inc | 180,000 MT | ISO 9001, IATF 16949 | Full-spectrum metallurgical lab | 12-15 days |

| Global Forge Solutions | 220,000 MT | ISO 14001, AS9100D | Automated ultrasonic testing | 8-10 days |

| TechnoSteel Industries | 150,000 MT | ISO 45001, NADCAP | Real-time spark spectroscopy | 10-14 days |

Customized Production Solutions

Leading SWRCH15A manufacturers offer extensive customization protocols addressing specialized application requirements. Surface treatment options include phosphating, coppering, and specialized lubrication coatings that reduce forming friction by up to 40%. Dimensional modifications accommodate client-specific tolerances from ±0.005mm for micro-fasteners to custom coil configurations up to 3-ton bundles. Proprietary annealing processes can adjust material hardness within 5 HRB points of specification, optimizing performance for high-strength bolt production or complex cold-headed components.

Industrial Implementation Case Studies

Automotive manufacturers have documented 17% reduction in fastener failure rates after transitioning to premium-grade SWRCH15A for suspension components. A major appliance producer eliminated thread-rolling defects entirely by implementing customized surface-treated wire rods, reducing scrappage by $460,000 annually. In aerospace applications, tight-tolerance SWRCH15A fasteners have withstood vibration testing exceeding military specifications by 28%, demonstrating remarkable fatigue resistance in critical assemblies exposed to extreme operational stresses.

Strategic Advantages of Certified SWRCH15A Suppliers

Established SWRCH15A suppliers provide critical value beyond basic material supply, including comprehensive technical support throughout production cycles. Partnering with certified manufacturers ensures compliance with international material standards while providing traceability documentation for regulated industries. Leading facilities now incorporate blockchain technology for immutable material certification, while dedicated application engineers assist with tooling design optimization. Such partnerships deliver measurable ROI, with documented 23% reduction in manufacturing downtime and 15% improvement in cold forging tool longevity when sourcing from qualified SWRCH15A suppliers.

(swrch15a)

FAQS on swrch15a

Q: What industries commonly use SWRCH15A steel wire rods?

A: SWRCH15A is widely used in automotive, electronics, and construction industries for manufacturing fasteners like screws, bolts, and rivets due to its excellent cold-heading properties and durability.

Q: How to identify a reliable SWRCH15A manufacturer?

A: Look for manufacturers with certifications (e.g., ISO 9001), proven industry experience, and positive client testimonials. Ensure they adhere to strict quality control and provide material test reports.

Q: What production capabilities should a SWRCH15A factory have?

A: A reputable SWRCH15A factory should offer high-volume production (e.g., 50,000+ tons annually), advanced cold-forming machinery, and rigorous testing processes to meet international standards.

Q: Do SWRCH15A suppliers provide customized specifications?

A: Yes, most suppliers offer customization in diameter, surface finish, and packaging. Confirm their ability to meet specific chemical composition or mechanical property requirements before ordering.

Q: What certifications are critical when sourcing SWRCH15A materials?

A: Key certifications include ISO 9001 for quality management, ISO 14001 for environmental compliance, and RoHS for restricted substances. Always request mill certificates for traceability.

-

High-Performance Tundish Dry Vibrator for Steel Casting

NewsJul.25,2025

-

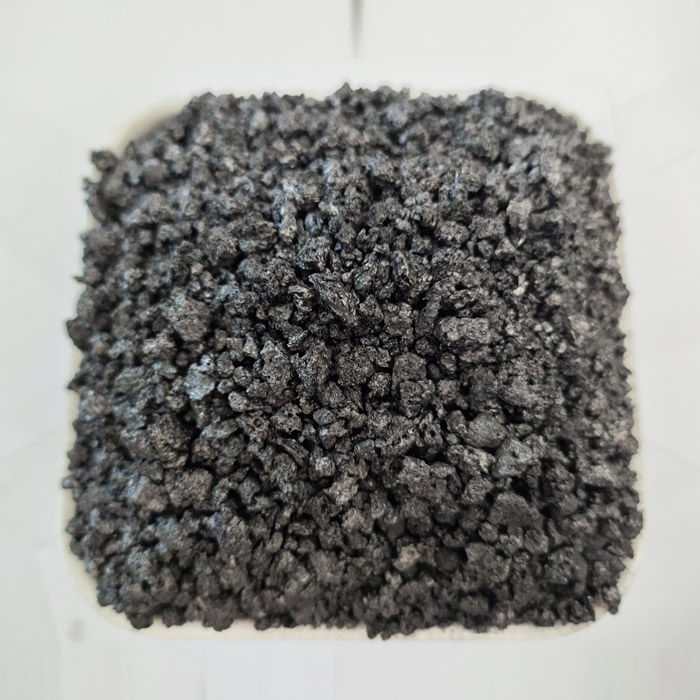

Top Carbon Petroleum Coke Exporters – Reliable Manufacturer & Supplier

NewsJul.24,2025

-

Environmentally Friendly Granule Covering Agent for Sustainable Solutions

NewsJul.23,2025

-

High-Performance Tundish Dry Vibrator for Continuous Casting

NewsJul.22,2025

-

First Bauxite Exporters | Top-Quality Global Supply

NewsJul.22,2025

-

```text High-Performance Insulation Cup Materials Exporters | Quality

NewsJul.21,2025