سبتمبر . 06, 2024 21:53 Back to list

High-Quality Calcined Bauxite Manufacturers | Superior Bauxite Processing

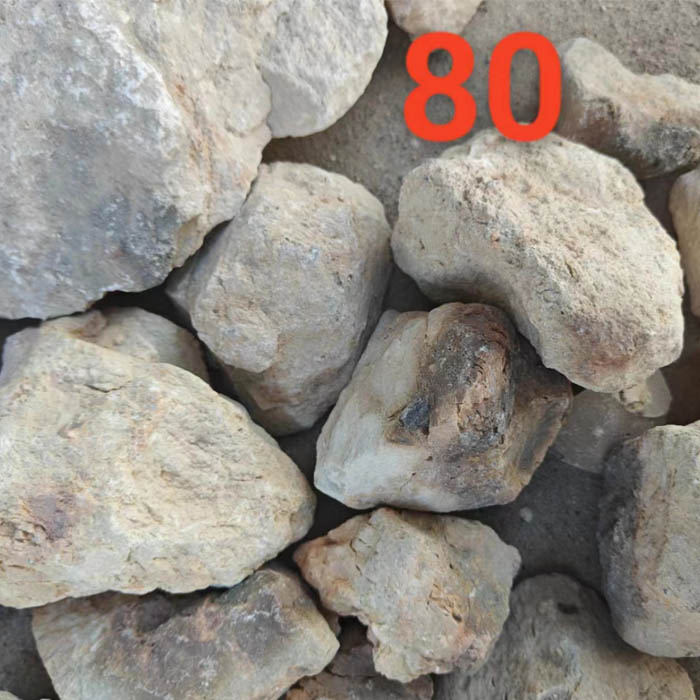

Calcined bauxite is a crucial industrial material primarily used in the production of alumina and as a primary raw material in various applications, including refractory products, steelmaking, and ceramic manufacturing. Calcined bauxite consists of bauxite ore that undergoes a high-temperature calcination process, which enhances its properties for specialized uses. The global demand for calcined bauxite has led to the establishment of numerous dedicated factories around the world.

Calcined bauxite factories are strategically located near bauxite mines to minimize transportation costs and optimize the supply chain. These facilities typically employ advanced technologies to ensure efficient processing. The calcination process involves heating bauxite ore at temperatures ranging from 1,200 to 1,500 degrees Celsius. This extreme heat causes the removal of moisture and the transformation of the chemical composition, resulting in a dense, hard material with high alumina content.

One of the primary applications of calcined bauxite is in the production of aluminum oxide, which is a key ingredient in the aluminum industry. Additionally, its properties make it an excellent choice for refractory materials, which can withstand high temperatures and are therefore essential in steel production and other high-heat applications. The demand for high-performance refractories is growing, driven by the increasing need for energy-efficient production methods in industries such as steel, cement, and glass manufacturing.

calcined bauxite factories

Moreover, calcined bauxite is also used in road construction as an aggregate material, providing high friction and skid resistance, which enhances road safety. Its unique properties make it an essential component in the development of antiskid surfaces, ensuring durability and performance.

In terms of environmental impact, modern calcined bauxite factories are adopting sustainable practices to minimize their carbon footprint. These include utilizing renewable energy sources, recycling waste materials, and implementing water conservation techniques in their processes. By adhering to environmental regulations and striving for sustainability, these factories not only contribute to the industrial landscape but also demonstrate a commitment to responsible manufacturing.

As demand continues to grow, the calcined bauxite industry faces challenges such as sourcing high-quality raw materials and adapting to fluctuating market conditions. However, with technological advancements and a focus on sustainability, calcined bauxite factories have the potential to thrive and contribute significantly to various industries. Through innovation and efficient practices, they play a vital role in meeting the world’s increasing demand for this essential mineral resource.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025