dec . 10, 2024 17:57 Back to list

iron on powder factories

The Growth and Importance of Iron-On Powder Factories

In recent years, the textile industry has witnessed a significant transformation, with innovations paving the way for more efficient and effective production methods. Among these innovations, iron-on powders have emerged as a popular solution in the realm of fabric application and design. Iron-on powder factories have sprung up to meet the increasing demand for easy-to-use adhesive solutions, revolutionizing how consumers and businesses alike approach textile embellishment and repairs.

What is Iron-On Powder?

Iron-on powder is a specialized product designed to bond fabrics together or adhere patches and embellishments to garments. This powder typically consists of heat-activated adhesives that, when applied using a household iron, melt and fuse to the fabric, creating a strong and durable bond. Iron-on powders are commonly used in crafting, DIY projects, and even professional textile applications due to their convenience and ease of use.

The Manufacturing Process

The manufacturing of iron-on powders involves several key steps. First, high-quality polymer resins are selected as the primary adhesive component. These resins are mixed with various additives to enhance their performance, such as improving flexibility, heat resistance, and wash durability. Once the ideal blend is achieved, the mixture undergoes melting and granulation processes, resulting in the fine powder form that consumers purchase.

Afterward, rigorous quality control measures are implemented to ensure that the iron-on powder meets industry standards. This includes testing for heat activation temperatures and adhesive strength. Once approved, the product is packaged for distribution to retailers and consumers.

The Economic Impact

iron on powder factories

Iron-on powder factories have not only changed the landscape of adhesive products but have also made significant contributions to the economy. The surge in demand for DIY solutions and custom apparel has led to the establishment of numerous manufacturing plants around the globe. These factories create jobs, provide local communities with economic support, and contribute to the overall growth of the textile industry.

Moreover, the rise of e-commerce has transformed the way iron-on powders are marketed and sold. Businesses can now reach a global audience through online platforms, making it easier for consumers to access these innovative products. This shift has encouraged factories to diversify their offerings, catering to various markets, from fashion and home decor to educational institutions looking for cost-effective solutions for uniforms and projects.

Environmental Considerations

While the growth of iron-on powder factories has its economic benefits, it also raises concerns about environmental sustainability. The production of synthetic fibers and adhesives often involves the use of petrochemicals, which have negative environmental impacts during both production and disposal. In response, many forward-thinking factories are now adopting eco-friendly practices. This includes using biodegradable materials for powders and developing sustainable manufacturing processes that reduce waste and emissions.

Moreover, consumer awareness regarding environmentally friendly products is on the rise. Factories that can offer eco-conscious alternatives are well-positioned to thrive in this changing market landscape. As sustainability becomes a priority for consumers, the future of iron-on powder factories will likely depend on their ability to innovate while also reducing their ecological footprint.

Conclusion

The emergence of iron-on powder factories marks a significant advancement in the textile and crafting industries. By simplifying the process of fabric bonding, these factories are empowering consumers to express their creativity and make repairs more accessible than ever before. As the demand for such products continues to grow, it is crucial for manufacturers to balance economic success with environmental responsibility. By embracing sustainable practices, iron-on powder factories can ensure their longevity and contribute positively to the future of the industry. With technology and awareness advancing rapidly, the potential for innovation in this sector remains vast, promising an exciting future for both producers and consumers alike.

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

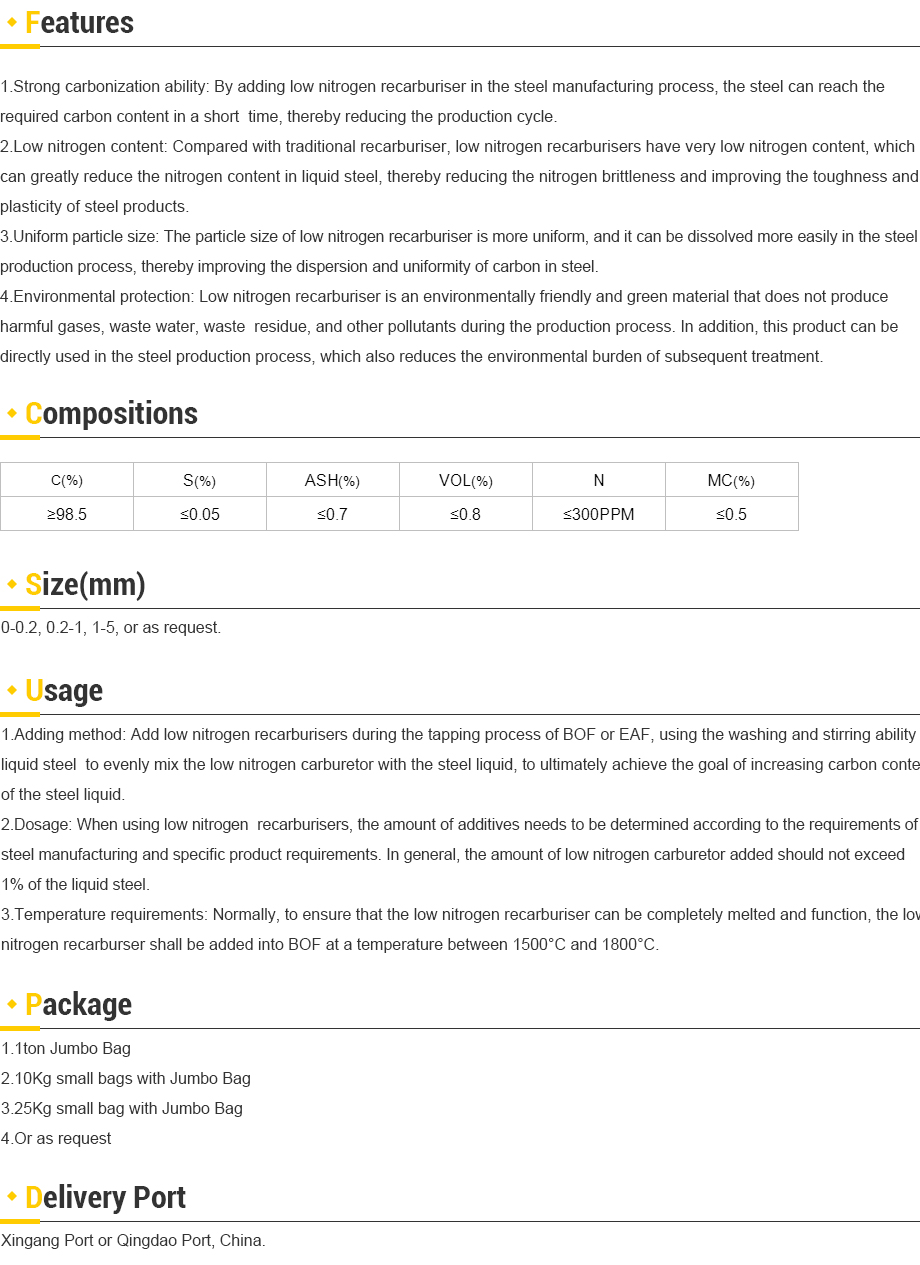

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025

-

Tundish Dry Vibrator: Fast, Durable Refractory Linings

NewsAug.14,2025