Dec . 05, 2024 15:16 Back to list

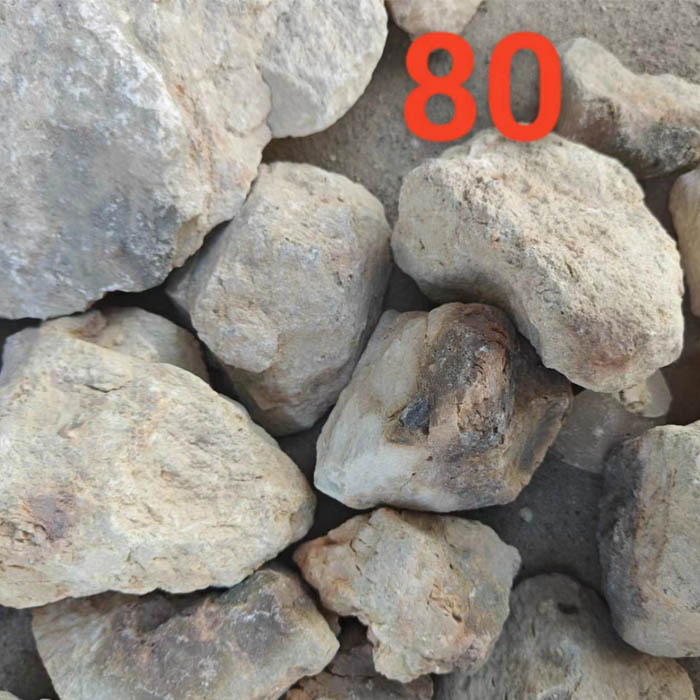

activated carbon as adsorbent manufacturer

Activated Carbon as an Efficient Adsorbent A Comprehensive Overview

Activated carbon is increasingly recognized as a versatile and effective adsorbent used in a myriad of applications ranging from industrial processes to environmental remediation. Its unique properties make it an ideal choice for various manufacturers seeking to optimize their production processes and enhance product quality. This article aims to delve into the characteristics, manufacturing processes, applications, and benefits of activated carbon as an adsorbent.

Understanding Activated Carbon

Activated carbon, also known as activated charcoal, is a porous material with a high surface area. It is produced from carbon-rich materials such as wood, coconut shells, coal, and peat through a process involving carbonization and activation. During carbonization, the raw material is heated in the absence of oxygen, which drives off volatile compounds and begins to reorganize the carbon structure. The subsequent activation process, typically achieved through physical or chemical means, develops an extensive pore structure, dramatically increasing the surface area available for adsorption.

Key Properties of Activated Carbon

1. High Surface Area The surface area of activated carbon can exceed 1,000 m² per gram. This vast surface area provides numerous sites for adsorbing various substances, making it effective for removing impurities.

2. Porosity The porous nature of activated carbon allows it to trap molecules from gases and liquids within its structure. This porosity can be tailored during the activation process, leading to different types of activated carbon suited for specific applications.

3. Chemical Reactivity Activated carbon can be treated with various chemicals to enhance its reactivity and selectivity towards specific adsorbates. This enables manufacturers to customize activated carbon for targeted applications—ranging from air purification to wastewater treatment.

Manufacturing of Activated Carbon

The manufacturing process of activated carbon involves two primary methods physical activation and chemical activation

.activated carbon as adsorbent manufacturer

- Physical Activation This method generally involves two main steps. First, the raw material is carbonized in a low-oxygen environment, followed by activation usually with steam or carbon dioxide at high temperatures. This process generates a highly porous structure.

- Chemical Activation In this method, the precursor material is impregnated with a chemical agent, such as phosphoric acid or potassium hydroxide, before undergoing carbonization. This approach typically operates at lower temperatures and yields activated carbon with a higher surface area in a shorter time.

Applications of Activated Carbon

Activated carbon is utilized in a broad spectrum of applications due to its adsorptive capabilities

1. Water Treatment Activated carbon is extensively used in municipal and industrial water treatment processes to remove organic compounds, chlorine, and other contaminants, ensuring safe drinking water.

2. Air Purification In air filtration systems, activated carbon effectively captures volatile organic compounds (VOCs), odors, and harmful gases, thus improving indoor air quality.

3. Industrial Processes It plays a crucial role in industries such as food and beverage, pharmaceuticals, and petrochemicals to purify products and remove unwanted substances.

4. Medical Applications Activated carbon is employed in medical fields to treat poisonings and overdoses, absorbing toxic substances in the gastrointestinal tract.

Conclusion

The versatility and efficiency of activated carbon as an adsorbent make it an invaluable resource across various industries. Manufacturers benefit from its unique characteristics and customizable production processes, enabling them to address specific challenges and improve product output. As environmental concerns continue to rise, the demand for effective treatment solutions will likely drive further innovations in activated carbon manufacturing and applications. Therefore, investing in activated carbon technology not only enhances operational efficiency but also contributes significantly to sustainability efforts within industry practices. Embracing activated carbon as a choice adsorbent is a step toward a cleaner, safer, and more efficient future in various sectors.

-

Tundish Dry Vibrator: Boost Steel Casting Performance

NewsAug.23,2025

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025