Dec . 04, 2024 20:36 Back to list

Properties and Applications of Low Carbon Steel Wire Rods in Manufacturing Industries

Understanding Low Carbon Steel Wire Rod A Comprehensive Overview

Low carbon steel wire rod is an essential material utilized across a multitude of industries, ranging from construction to automotive manufacturing. Characterized by its ductility and malleability, low carbon steel wire rod possesses mechanical properties that make it suitable for a range of applications. In this article, we will explore the composition, production methods, applications, and benefits of low carbon steel wire rod, as well as its economic and environmental implications.

Composition and Properties

Low carbon steel generally contains less than 0.3% carbon content, making it softer compared to medium and high carbon steels. This low carbon concentration lends the steel a variety of advantageous properties, including enhanced ductility, weldability, and formability. Other alloying elements, such as manganese, can be added to improve strength and hardness slightly without significantly impacting the material's overall characteristics.

The key properties of low carbon steel wire rod include

1. Ductility The ability to deform under tensile stress allows it to be drawn into wire forms without breaking. 2. Malleability This property enables the material to be easily shaped and formed into desired products. 3. Weldability Low carbon steel can be welded efficiently, which is crucial in construction and manufacturing applications. 4. Cost-Effectiveness It is generally less expensive than higher carbon steels, making it an economical choice for many producers.

Production Methods

The production of low carbon steel wire rod involves several stages, including casting, rolling, and finishing. The process typically begins with the melting of raw materials – iron ore, scrap steel, and alloy elements – in a furnace. After obtaining molten steel, it is cast into billets or slabs.

These semi-finished products are then heated and passed through a series of rollers in a rod mill to attain the desired diameter and length. The standard diameter for wire rods typically ranges from 5.5 mm to 16 mm, although custom sizes can also be produced. Following the rolling process, the wire rod undergoes cooling, coiling, and final surface treatment to enhance its performance and durability.

low carbon steel wire rod

Applications

Low carbon steel wire rod is widely used in various applications, owing to its favorable properties. Some common uses include

1. Construction Industry Low carbon steel wire is often used for reinforcing concrete in the form of rebar and mesh, providing structural integrity to buildings and infrastructure. 2. Automotive Components Wire rods are used to manufacture various automotive parts, such as springs, fasteners, and wire harnesses. 3. Wire Products The material is commonly drawn into wires for fencing, cables, and other wire forms used in a multitude of consumer and industrial applications. 4. Manufacturing It serves as a raw material for making nails, screws, and other fasteners that are essential in manufacturing processes.

Economic and Environmental Impact

The production and use of low carbon steel wire rod have significant economic implications. The versatility of this material contributes to various sectors, driving economic growth and job creation. Furthermore, its affordability makes it accessible for small to medium enterprises, fostering innovation and competitiveness in manufacturing.

From an environmental perspective, low carbon steel can be seen as a sustainable option. Its production often incorporates recycled materials (scrap steel), reducing the demand for virgin resources and lowering energy consumption. Additionally, advancements in steel manufacturing continue to enhance the energy efficiency of the production processes while reducing emissions.

Conclusion

In summary, low carbon steel wire rod is a vital material that plays a crucial role in various industries. Its desirable properties, combined with cost-effectiveness and versatility, make it an ideal choice for numerous applications. As industries increasingly prioritize sustainability, low carbon steel wire rod, with its potential for recycling and lower environmental impact, is well-positioned to meet future demands. Understanding its characteristics and applications can help industries continue to innovate while addressing both economic and environmental challenges.

-

Fe-C Composite Pellets for BOF: Enhance Efficiency, Lower Steelmaking Costs

NewsAug.25,2025

-

Durable Building Material for Round Wall Exporters | Custom Shapes

NewsAug.24,2025

-

Tundish Dry Vibrator: Boost Steel Casting Performance

NewsAug.23,2025

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

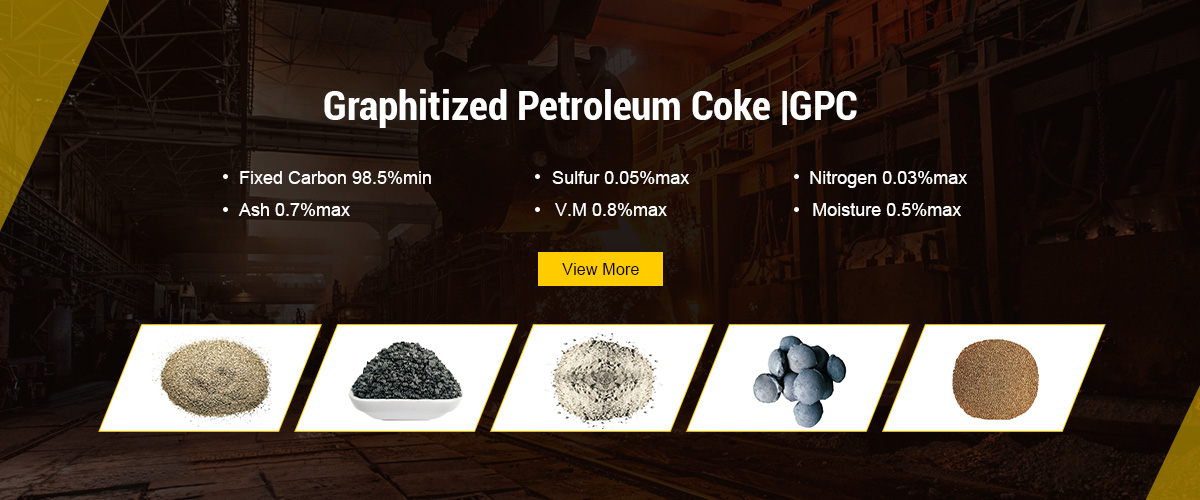

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025