Pro . 11, 2024 11:18 Back to list

rock wall materials manufacturers

Understanding Rock Wall Materials Manufacturers

Rock walls, often admired for their natural beauty and structural integrity, have become increasingly popular in landscaping and construction. The manufacturers of rock wall materials play a crucial role in providing high-quality products that meet the diverse needs of both residential and commercial projects. This article delves into the various aspects of rock wall materials manufacturers, including the types of materials they produce, the manufacturing process, and emerging trends in the industry.

Types of Rock Wall Materials

Manufacturers of rock wall materials offer a variety of products tailored to specific applications. The most common materials include

1. Natural Stone This includes granite, limestone, and sandstone. Natural stone provides aesthetic appeal and durability, making it a favored choice for building rock walls in gardens, patios, and retaining structures.

2. Concrete Block Concrete blocks that mimic the appearance of natural stone are a popular alternative. They are cost-effective, lightweight, and easier to handle, which makes them a preferred choice for DIY projects and large-scale construction.

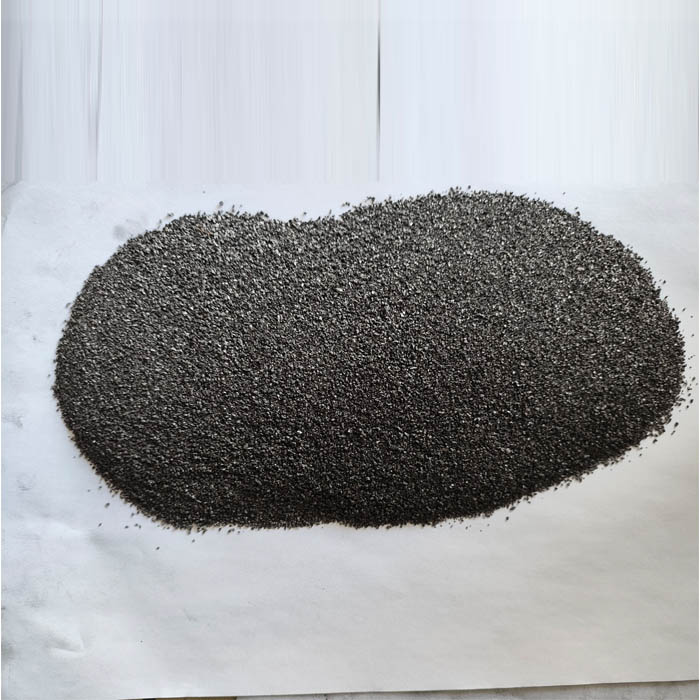

3. Reconstituted Stone This engineered product combines crushed stone and aggregates with resins to create a versatile material. Reconstituted stone offers the appearance of natural stone at a lower cost and can be molded into various shapes and sizes to meet specific design requirements.

4. Gabions These are wire mesh containers filled with rocks or stones, often used for erosion control and structure stabilization. Manufacturers provide various sizes of gabions, which can be adapted to suit different landscaping needs.

The Manufacturing Process

The production of rock wall materials involves several stages, from sourcing raw materials to final distribution. The process typically includes

1. Sourcing Manufacturers source raw materials from quarries, ensuring they adhere to environmental and sustainability standards. The quality of the stone is crucial, as it directly affects the durability and appearance of the final product.

2. Cutting and Shaping For natural stones, skilled artisans or machines cut and shape the materials according to specifications. Advanced technology, such as diamond wire saws, ensures precision and minimizes waste. For concrete and reconstituted stone, molds are created to produce consistent shapes and sizes.

rock wall materials manufacturers

3. Finishing After cutting, the stones may undergo finishing processes, including polishing, honing, or sealing, depending on desired aesthetics and protective measures. Finishing not only enhances the appearance but also increases the material's durability.

4. Quality Control Manufacturers implement strict quality control measures to ensure that all products meet industry standards. This includes testing for strength, weather resistance, and color consistency.

5. Distribution Once products pass quality checks, they are packaged and distributed to retailers or directly to contractors. Efficient logistics systems are essential to ensuring timely delivery and maintaining product integrity during transport.

Emerging Trends

The rock wall materials industry is witnessing several trends driven by advancements in technology and a growing emphasis on sustainability

1. Sustainable Practices Many manufacturers are adopting eco-friendly production methods, utilizing recycled materials, and reducing waste to minimize their environmental impact. This trend is also reflected in the increasing popularity of permeable paving solutions that allow water to permeate the soil, reducing runoff.

2. Customization With advances in technology, manufacturers can offer customized products tailored to specific project needs. This includes bespoke sizes, shapes, and colors, allowing architects and designers to create unique landscapes.

3. Integration of Technology The use of technology in manufacturing processes, from automated cutting machines to software for inventory management, has improved efficiency and reduced costs. Emerging technologies such as 3D printing may also play a role in the future, allowing for even more intricate designs.

4. Education and Support Leading manufacturers are increasingly focusing on providing support and resources for customers, including installation guides, design tools, and technical assistance. This commitment to customer service enhances client satisfaction and project success.

Conclusion

Rock wall materials manufacturers are integral to the construction and landscaping industries, providing a range of products that combine beauty and durability. As the demand for sustainable and innovative materials grows, manufacturers will continue to adapt, ensuring that they meet the evolving needs of their customers. Understanding the complexities of this industry is essential for anyone looking to engage with rock wall materials, whether for personal projects or professional applications.

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025