okt . 06, 2024 21:06 Back to list

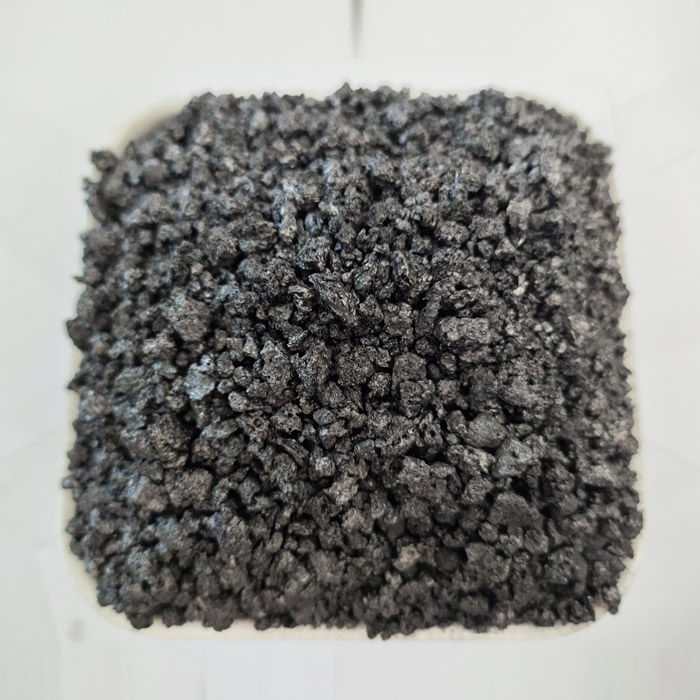

china thermal insulation materials furnace

The Evolution of Thermal Insulation Materials in China’s Furnace Industry

In recent years, the demand for thermal insulation materials has surged in China, particularly in the furnace industry. As the country continues to industrialize and expand its manufacturing capabilities, efficient thermal management has become crucial for energy conservation, safety, and operational efficiency. The interplay between technology and material science has led to the development and application of advanced thermal insulation solutions.

Thermal insulation materials serve a pivotal role in furnaces by minimizing heat loss during high-temperature operations. This is particularly important in industries such as metallurgy, ceramics, and petrochemicals, where furnaces are central to production processes. Traditionally, refractory materials made from clay or silica were standard; however, advances in material science have led to the emergence of high-performance insulation products, including ceramic fiber, calcium silicate, and various aerogels.

One of the most significant developments in the thermal insulation sector is the adoption of ceramic fiber insulation. Known for its exceptional thermal stability and low thermal conductivity, ceramic fiber can withstand extreme temperatures, making it ideal for high-temperature furnaces. Its lightweight nature also contributes to reduced structural load, which is an essential consideration in furnace design.

china thermal insulation materials furnace

Moreover, calcium silicate boards are becoming increasingly popular due to their excellent thermal and mechanical properties. These boards are not only highly resistant to moisture but also offer superior compressive strength, making them suitable for various furnace applications. Their ease of installation further enhances their desirability among manufacturers.

In addition to traditional insulation options, the growing trend of incorporating nanotechnology into thermal insulation materials is redefining the landscape. Nanostructured materials exhibit remarkable thermal resistance and durability, allowing companies to develop more efficient and longer-lasting insulation solutions. This innovation has significant implications for energy savings, as reduced heat loss directly correlates with lower operating costs.

As China pushes towards greener manufacturing practices, the role of advanced thermal insulation materials becomes increasingly vital. The government’s emphasis on energy efficiency and sustainability is driving research and development in this field. Companies are increasingly focused on finding eco-friendly insulation solutions that not only meet performance standards but also adhere to environmental regulations.

In conclusion, the evolution of thermal insulation materials in China's furnace industry reflects a broader trend towards innovation and efficiency. The integration of advanced materials and nanotechnology is helping manufacturers enhance the performance of their furnaces while contributing to energy conservation and sustainability goals. As the industry continues to evolve, the ongoing development of high-performance insulation materials will undoubtedly play a crucial role in shaping the future of furnace operations in China and beyond.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025