Sep . 24, 2024 19:52 Back to list

Essential Materials Required for Exporting Brick Wall Construction

Key Materials Needed for Brick Wall Construction

Building a brick wall involves the careful selection of various materials that contribute to its structural integrity, aesthetics, and longevity. Brick walls are not only popular for their durability but also for their aesthetic appeal in both residential and commercial construction. For exporters in the construction industry, understanding the essential materials required for brick wall construction is vital to supplying clients with the best products.

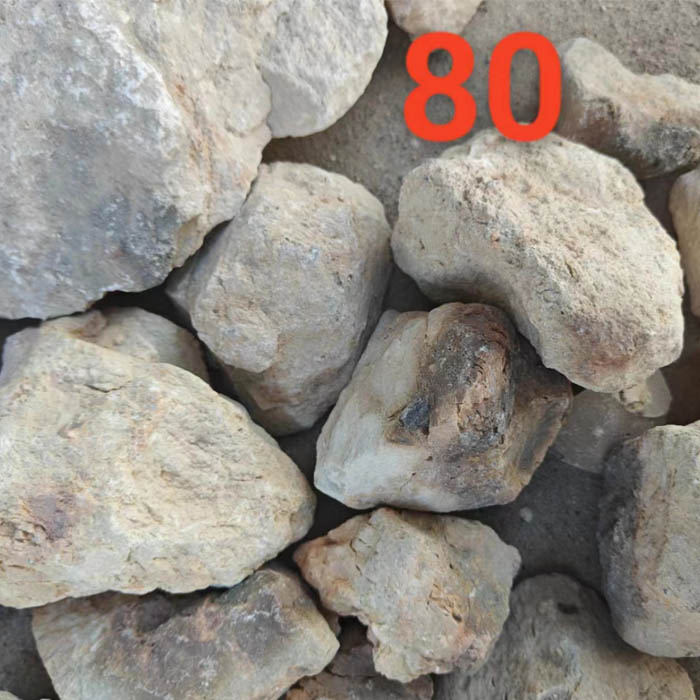

First and foremost, the primary material needed for a brick wall is the bricks themselves. Bricks come in a variety of types, including clay, concrete, and fly-ash bricks. Clay bricks are the most traditional choice, known for their thermal insulating properties and timeless appearance. Concrete bricks offer higher strength and are commonly used in high-stress areas. Fly-ash bricks, made from industrial waste, have gained popularity due to their eco-friendly nature and lightweight characteristics.

To bind the bricks together, mortar is crucial. Mortar typically consists of cement, sand, and water, providing strength and stability to the brick wall. The right mix ratio can significantly affect the wall’s durability. Exporters need to ensure they provide quality mortar materials that adhere well to the bricks and withstand the elements.

materials needed for brick wall exporters

Reinforcement materials, such as steel reinforcements or wall ties, are also essential for brick walls, especially in earthquake-prone areas. These elements help improve the lateral stability of the structure. High-quality steel that is resistant to rust and corrosion should be prioritized in exports to ensure longevity.

Moreover, additional resources such as scaffolding and formwork are necessary during the construction phase. Scaffolding provides safety and access for bricklayers while formwork ensures accurate shapes and dimensions during the mortar curing process.

Lastly, additives may be included to enhance specific properties of the mortar or bricks. For instance, water-retaining agents can improve workability and adhesion, while anti-fungal treatments can provide added protection against weather-induced damage.

In conclusion, successful brick wall construction relies on a combination of quality bricks, mortar, reinforcement materials, and additional resources like scaffolding. Exporters must be knowledgeable about these essential materials to meet the demands of the construction industry effectively. By offering high-quality products, they not only contribute to the creation of sturdy structures but also promote sustainable practices in the building sector. This holistic understanding of brick wall materials positions exporters for success in a competitive market.

-

High-Quality Traditional Recarburiser Trusted Supplier & Manufacturer for Steelmaking

NewsJul.08,2025

-

High Quality Fe-C Composite Pellets Reliable Manufacturer & Exporters

NewsJul.08,2025

-

High-Quality Magnesium Silicate Adsorbent Manufacturer & Supplier Leading Factory for Adsorbents

NewsJul.08,2025

-

Lightweight Wall Powder – Premium Lightweight Wall Powder Suppliers & Manufacturer

NewsJul.07,2025

-

High Quality Steel Wire Rod Reliable Mild Steel Wire Rod Manufacturer & Supplier

NewsJul.07,2025

-

ML08AL-Y Supplier & Manufacturer High-Quality ML08AL Factories Reliable Exporter

NewsJul.07,2025