Oct . 01, 2024 07:43 Back to list

Trends and Insights on China's Steel and Graphite Industry Performance

The Role of Graphite in China's Steel Industry

Graphite plays a vital role in various industrial applications, with its significance particularly pronounced in the steel industry. As China stands as the largest producer and consumer of steel globally, understanding the interplay between graphite and steel production is crucial. This article delves into the importance of graphite in China’s steel sector, the implications of its use, and the future outlook for this essential material.

Graphite An Essential Component in Steelmaking

Graphite is primarily used in the steel-making process as a component of refractory materials and as a carbon source. In a typical steel production cycle, raw materials are smelted in a blast furnace, where iron ore, coke, and limestone are combined at high temperatures. The coke, which is produced from coal, contains significant amounts of carbon, and it is here that graphite plays a complementary role.

Graphite's unique properties—such as high thermal conductivity, resistance to thermal shock, and chemical inertness—make it an excellent choice for refractory linings in furnaces and converters. These linings protect the furnace structure from the corrosive effects of molten metal and help maintain temperature and efficiency during steel production. Furthermore, the addition of graphite can enhance the mechanical properties of steel, improving its strength and durability.

China's Steel Production A Graphite Perspective

China's steel production industry has witnessed a dramatic expansion over the past few decades, driven by urbanization and infrastructure development. In 2022 alone, the country produced approximately 1.0 billion tonnes of crude steel—a staggering figure representing over half of the global output. This growth in steel production inherently translates to increased demand for graphite.

Most steel grades require a controlled amount of carbon, which may be achieved through the addition of graphite. As the steel sector evolves towards producing higher-quality and specialized steels—such as those used in automotive and construction applications—there is a growing recognition of the need for refined graphite inputs to achieve the desired material properties.

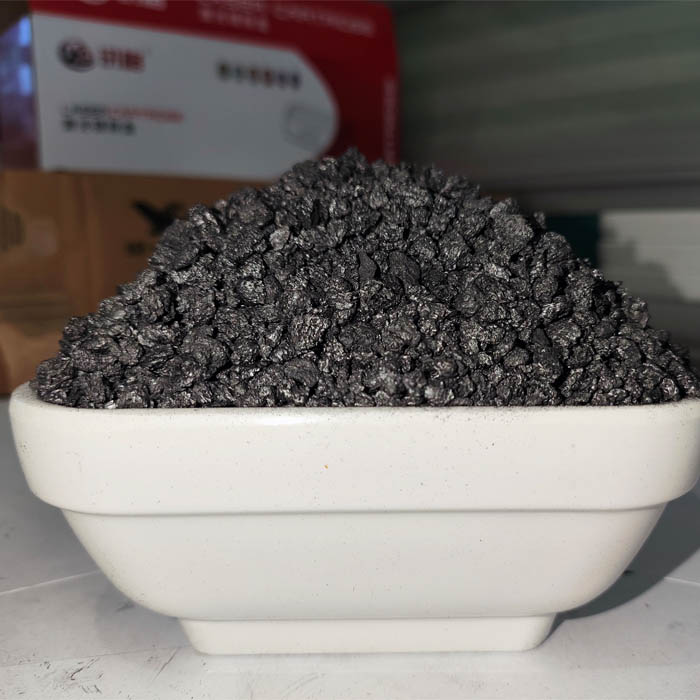

china steel graphite

Environmental Considerations and Sustainable Practices

Despite its advantages, the increasing demand for graphite in China's steel industry comes with environmental challenges. The mining and processing of natural graphite can lead to ecological degradation, water pollution, and significant carbon emissions. Consequently, there is a pressing need for the industry to adopt sustainable mining practices and to explore synthetic graphite alternatives.

Moreover, innovative technologies are being developed to recycle graphite from steel production by-products. This can significantly reduce environmental impact, cut costs, and promote a circular economy within the steel industry. The Chinese government has also put pressure on industries to minimize their carbon footprints, necessitating a shift towards more eco-friendly practices, including the use of artificially produced graphite.

Future Outlook for Graphite in China's Steel Sector

Looking ahead, the relationship between graphite and steel in China is poised for transformation. With the country’s commitment to reducing carbon emissions by 2030 and achieving carbon neutrality by 2060, the steel industry must pivot towards more sustainable practices. This includes not only the utilization of graphite but also exploring alternative carbon sources and methods of production that lessen environmental impact.

Technological advancements in steelmaking, such as electric arc furnaces and hydrogen-based reduction processes, may alter the role of graphite in the future. These innovations could lead to a decreased reliance on traditional carbon inputs, creating both challenges and opportunities for graphite producers.

Conclusion

In summary, graphite is an indispensable material in China's flourishing steel industry, significantly influencing the production process and final product quality. While the challenges associated with mining and environmental impact cannot be overlooked, the path towards sustainability offers potential benefits for both the industry and the environment. As China navigates this complex landscape, the future of graphite in steel production remains a crucial area of focus that warrants continual exploration and adaptation.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025