Dec . 05, 2024 15:27 Back to list

liquid steel manufacturers

Liquid Steel Manufacturers A Pillar of Modern Industry

Liquid steel, produced through advanced metallurgical processes, is a cornerstone of modern manufacturing and construction. It’s the primary material used in countless applications, ranging from buildings and bridges to automobiles and machinery. The industry is composed of various players, from large-scale steel mills to specialized manufacturers focused on unique steel products. This article delves into the world of liquid steel manufacturers, their processes, challenges, and the future of the industry.

The Steel Production Process

The journey from raw materials to liquid steel involves several complex stages. Manufacturers typically begin with the extraction of iron ore, which is then processed in blast furnaces. Here, the ore is heated with coke and limestone to produce molten iron. This molten iron is further refined in a steelmaking furnace, where impurities are removed, and alloying elements are added. The result is liquid steel, tailored for specific requirements.

Liquid steel can be produced using various methods, including the Basic Oxygen Process (BOP), Electric Arc Furnace (EAF), and Open Hearth Process. The BOP is the most widely used method due to its efficiency and cost-effectiveness, allowing manufacturers to convert iron into steel rapidly. The EAF, although typically used for recycling scrap steel, has gained popularity due to its flexibility and lower environmental impact.

Key Players in the Industry

Global leaders in liquid steel manufacturing include companies such as ArcelorMittal, Nippon Steel, and Tata Steel. These corporations have established extensive operations worldwide, driven by technological advancements and economies of scale. They invest significantly in research and development to improve production efficiency, reduce costs, and innovate new steel grades.

In addition to these giants, there are numerous smaller manufacturers specializing in niche markets. Some focus solely on producing high-strength steel for the automotive industry, while others might cater to infrastructure projects with specialized steel grades. This diversity boosts competition, thereby enhancing innovation and driving improvements across the sector.

liquid steel manufacturers

Economic and Environmental Challenges

Despite its vital role, the liquid steel manufacturing industry faces several challenges. Economically, fluctuations in raw material prices, such as iron ore and coke, can significantly impact profit margins. Additionally, global trade policies and tariffs can affect market access and pricing strategies for manufacturers.

Environmental concerns also pose a significant challenge. Steel production is energy-intensive and traditionally relies on fossil fuels, contributing to greenhouse gas emissions. As global awareness of climate change grows, manufacturers are under increasing pressure to adopt more sustainable practices. This includes exploring alternative energy sources, enhancing energy efficiency, and investing in carbon capture technologies.

The Future of Liquid Steel Manufacturing

As the demand for liquid steel continues to evolve, so too do the manufacturing processes. The future of the steel industry will likely be shaped by advancements in technology. Automation and digitalization are becoming integral to operations, allowing manufacturers to enhance productivity and reduce costs. Smart factories, powered by the Internet of Things (IoT) and artificial intelligence, promise to revolutionize production methods.

Moreover, the shift toward sustainability is gaining momentum. Many manufacturers are exploring the use of hydrogen-based steelmaking processes, which potentially reduce carbon emissions to near zero. Companies are also investing in closed-loop water systems and recycling initiatives to minimize waste and reduce their environmental footprint.

In conclusion, liquid steel manufacturers are essential to the fabric of modern industrial society. They face numerous challenges, including economic pressures and environmental impacts, but the industry's resilience and adaptability are remarkable. Through technological innovation and a commitment to sustainability, liquid steel manufacturers are not only meeting current demands but also paving the way for a greener, more efficient future. As we look ahead, the steel industry is poised for transformation, reinforcing its position as a cornerstone of global economic development.

-

Tundish Dry Vibrator: Boost Steel Casting Performance

NewsAug.23,2025

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

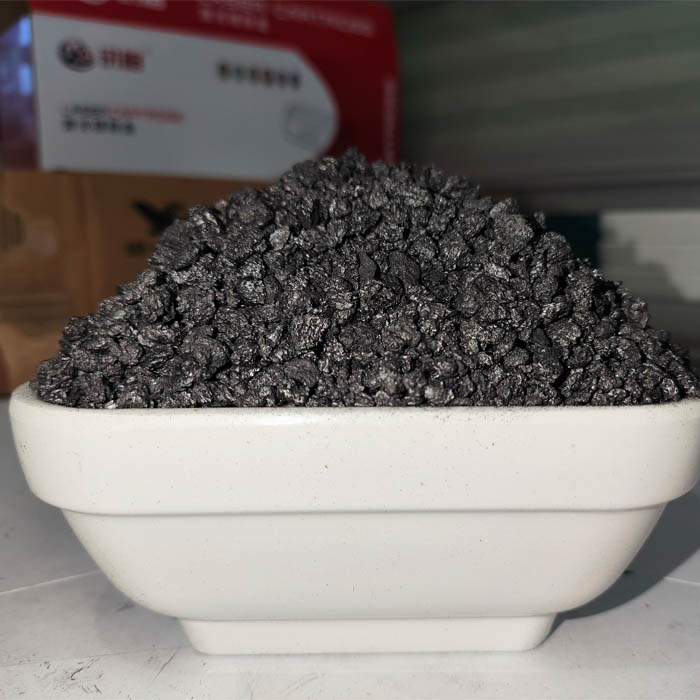

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025