Dec . 03, 2024 18:07 Back to list

powdered activated carbon sds manufacturers

Understanding Powdered Activated Carbon and Its Manufacturers

Powdered Activated Carbon (PAC) has become an essential material in various industries, particularly in water treatment, air purification, and food processing. Its high surface area and porous structure enable it to effectively adsorb a wide range of contaminants, making it indispensable for applications where filtration and purification are crucial. In this article, we will explore the significance of PAC, the role of its manufacturers, and key considerations when selecting a supplier.

What is Powdered Activated Carbon?

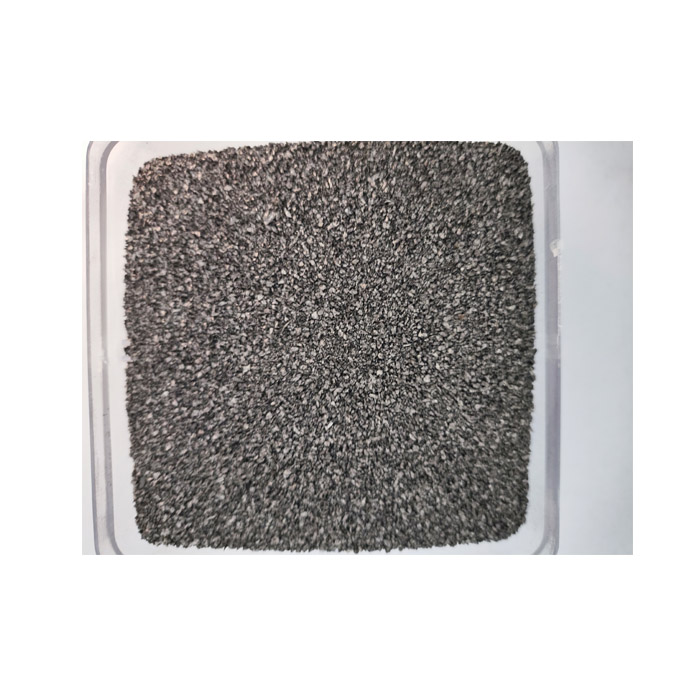

Powdered Activated Carbon is produced through the activation of carbonaceous materials such as coconut shells, coal, or wood. The activation process involves heating these materials at high temperatures in the presence of a gas, which creates a network of tiny pores. This extensive porosity increases the surface area significantly—ranging from 500 to 1500 m²/g—allowing PAC to effectively trap and hold impurities.

PAC is available in various particle sizes, typically ranging from 0.1 to 0.5 mm. This fine powder is ideal for adsorption processes in liquid-phase applications, where it can be easily mixed with water or other liquids for optimal contact with contaminants.

Applications of Powdered Activated Carbon

1. Water Treatment One of the primary uses of PAC is in municipal water treatment plants for removing organic compounds, chlorine, and other pollutants from drinking water. It helps in improving taste and odor, ensuring that the water is safe for consumption.

2. Air Quality Improvement PAC is also utilized in air purification systems to mitigate volatile organic compounds (VOCs), odors, and particulate matter. It plays a crucial role in maintaining indoor air quality, particularly in commercial and industrial settings.

3. Food and Beverage Industry In the food sector, PAC is used to decolorize and purify natural products. It contributes to the quality control processes that ensure food safety and compliance with health regulations.

4. Pharmaceuticals The pharmaceutical industry employs PAC in drug production and purification processes, taking advantage of its high adsorption capacity to remove impurities and enhance the final product's safety.

Importance of Manufacturers in the PAC Supply Chain

powdered activated carbon sds manufacturers

The quality of Powdered Activated Carbon heavily depends on the manufacturing process, raw material selection, and adherence to industry standards. Therefore, choosing the right manufacturer is critical for businesses that rely on PAC for their operations.

1. Quality Assurance Reputable manufacturers implement rigorous quality control measures throughout the production process. This ensures that the PAC produced meets the required specifications and performance standards necessary for various applications.

2. Sustainability With increasing awareness of environmental impacts, many manufacturers are focusing on sustainable sourcing of raw materials and eco-friendly production processes. This is crucial for companies looking to minimize their ecological footprint.

3. Customization and Technical Support Leading manufacturers often provide custom solutions tailored to specific customer needs, including different grades of PAC or specialized activation processes. Additionally, they offer technical support and guidance on best practices for using activated carbon effectively.

4. Compliance and Certification A reputable PAC manufacturer will have certifications indicating compliance with international standards, such as ISO, NSF, or FDA. This provides customers with confidence in the safety and efficacy of the product.

Key Considerations When Selecting PAC Manufacturers

When choosing a manufacturer for Powdered Activated Carbon, businesses should consider the following factors

- Reputation and Experience Look for manufacturers with a solid reputation and extensive experience in the industry. - Product Range Check if the manufacturer offers a variety of PAC products to meet different application needs. - Technical Expertise Ensure that the manufacturer has knowledgeable staff who can provide technical assistance and product recommendations. - Pricing and Delivery Compare prices while considering the quality of the products. Additionally, assess their delivery capabilities to ensure timely supply.

Conclusion

Powdered Activated Carbon is a vital resource across diverse industries, playing a crucial role in filtration, purification, and safety. The importance of choosing a reliable manufacturer cannot be overstated, as it directly impacts the effectiveness of PAC in enhancing product quality and environmental compliance. By considering the factors discussed above, businesses can make informed decisions when selecting a PAC supplier, ensuring optimal performance in their operations.

-

High Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.26,2025

-

Fe-C Composite Pellets for BOF: Enhance Efficiency, Lower Steelmaking Costs

NewsAug.25,2025

-

Durable Building Material for Round Wall Exporters | Custom Shapes

NewsAug.24,2025

-

Tundish Dry Vibrator: Boost Steel Casting Performance

NewsAug.23,2025

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025