sep . 04, 2024 02:38 Back to list

stone wall sub base material manufacturer

Stone Wall Sub Base Material A Comprehensive Guide for Manufacturers

When it comes to constructing durable and aesthetically pleasing stone walls, one of the most crucial considerations lies in selecting the right sub-base material. This foundational element not only supports the wall's weight but also plays a vital role in drainage, stability, and the overall longevity of the structure. This article aims to delve into the various types of sub-base materials used by manufacturers for stone walls, their properties, and the importance of quality sourcing.

What is a Sub Base Material?

In construction, a sub-base is typically a layer of material laid below the primary building material. For stone walls, the sub base provides a solid footing, ensuring that the stones remain stable and the wall retains its integrity over time. A well-prepared sub-base will prevent settling and shifting, which can lead to cracks, bulging, and other structural failures.

Common Types of Sub Base Materials

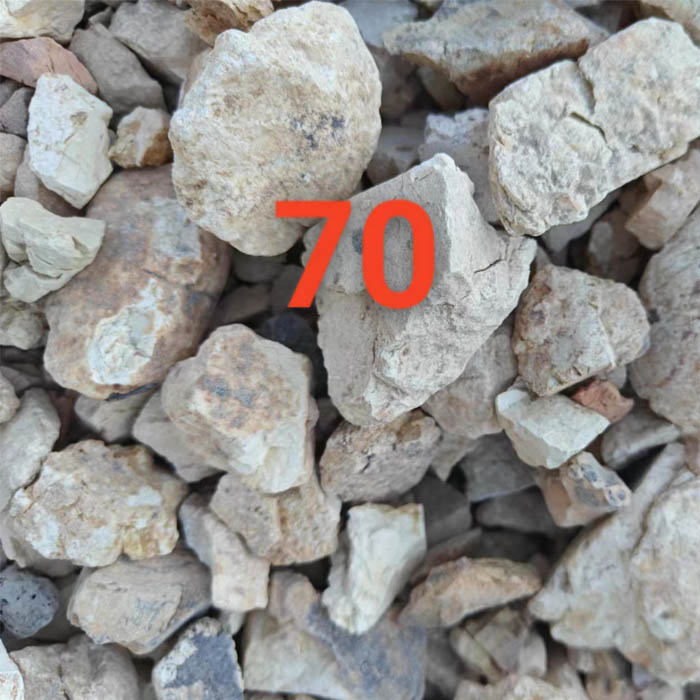

1. Crushed Stone One of the most widely used materials for stone wall sub-bases is crushed stone. This material is made from breaking down larger rocks, creating angular stones that interlock well when compacted. Crushed stone provides excellent drainage, helping to prevent water accumulation that can damage the wall.

2. Gravel Similar to crushed stone, gravel is a loose aggregation of small water-worn or weathered stones. While it offers good drainage, it lacks the interlocking properties of crushed stone, making it less stable without proper compaction and support. Gravel can be an economical choice for lighter stone walls.

3. Granular Fill This material consists of sand and small gravel, offering a mix that allows for good drainage while maintaining stability. Granular fill is often used in situations where vibration or movement is a concern, providing a flexible yet durable sub-base solution.

stone wall sub base material manufacturer

4. Compacted Sand Sand can also serve as a sub-base material when compacted properly. It is lightweight and easy to work with but lacks the load-bearing capacity of crushed stone or gravel. Compacting the sand is critical to prevent settling over time.

5. Concrete Slabs In some cases, manufacturers may opt for a concrete slab as a sub-base, particularly for taller or heavily loaded stone walls. A concrete base provides a solid foundation but may require special drainage considerations to prevent moisture buildup beneath the wall.

Importance of Quality Sourcing

When selecting sub-base materials, manufacturers must prioritize quality. Poor-quality materials can result in inadequate support, leading to premature wall failure. Therefore, sourcing from reputable suppliers is essential. A reliable manufacturer will provide materials that meet industry standards, ensuring durability and stability.

Moreover, proper installation techniques are equally important. Regardless of the sub-base material chosen, techniques such as proper compaction, layering, and drainage management will significantly impact the performance of the stone wall.

Conclusion

In summary, the choice of sub-base material in stone wall construction is critical for achieving a stable, durable, and attractive structure. Whether opting for crushed stone, gravel, granular fill, compacted sand, or concrete slabs, manufacturers must consider the specific requirements of the project at hand. Emphasizing quality sourcing and proper installation techniques will ultimately lead to successful stone wall constructions that stand the test of time. Understanding these materials and their properties can significantly influence the quality of the finished product, affirming the manufacturer's reputation in the industry.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025