Nov . 10, 2024 23:51 Back to list

Production Facility for Ferrous Iron Powder and Related Manufacturing Processes

The Fel Iron Powder Factory A Beacon of Innovation and Sustainability

In recent years, the demand for iron powder has surged due to its extensive applications across various industries, including metallurgy, pharmaceuticals, and additive manufacturing. At the forefront of this industry is the Fel Iron Powder Factory, a pioneering establishment that has carved a niche for itself by combining innovation with sustainable practices. This article explores the significance of the Fel Iron Powder Factory in the global market, its environmentally friendly approaches, and its contributions to industrial advancement.

A Brief Overview of Iron Powder Production

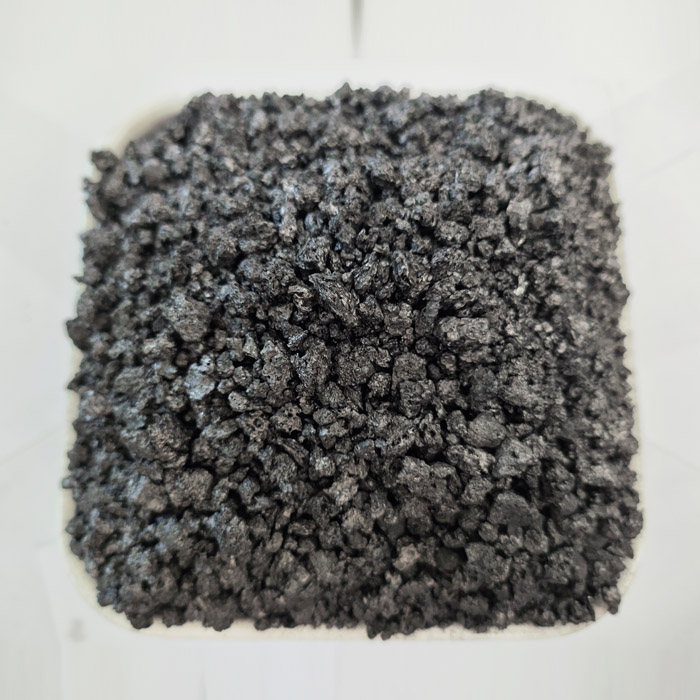

Iron powder is a finely ground metal powder with a variety of applications, ranging from the production of ferritic materials to use in 3D printing and sintering processes. Traditional methods of producing iron powder involve high-energy processes that not only consume significant resources but also generate substantial waste and environmental impact. This is where the Fel Iron Powder Factory distinguishes itself from conventional manufacturers.

Innovative Manufacturing Processes

The Fel Iron Powder Factory utilizes advanced production techniques that focus on efficiency and sustainability. By adopting atomization processes rather than traditional milling, the factory ensures a higher yield of quality iron powder while minimizing waste. Atomization involves converting molten iron into powder through a series of controlled processes that allow for precise particle size distribution and morphology.

The factory also invests in state-of-the-art technology, allowing for real-time monitoring and adjustments in production. This adaptability leads to improved product consistency and a reduction in defects, ultimately enhancing customer satisfaction. This commitment to quality and innovation positions the Fel Iron Powder Factory as a leader in the iron powder market.

Environmental Sustainability

In an era where industrial pollution and waste reduction are critical, the Fel Iron Powder Factory has made significant strides in promoting environmental sustainability. The factory employs a closed-loop water system that recycles water used in the cooling and cleaning processes, significantly reducing freshwater consumption. Furthermore, the facility is equipped with advanced filtration and scrubbing systems that minimize airborne emissions, ensuring compliance with stringent environmental regulations.

fel iron powder factory

Moreover, the factory is actively working towards reducing its carbon footprint by investing in renewable energy sources. Solar panels and wind turbines have been integrated into the facility's energy grid, allowing it to harness clean energy for production processes. This commitment to sustainability not only reduces operational costs but also serves as a model for other manufacturers striving to reduce their environmental impact.

Community Engagement and Economic Impact

The Fel Iron Powder Factory is not just a hub of innovation—it is also deeply committed to the local community. The factory has created numerous job opportunities, providing training and employment for skilled workers in the region. By engaging with local educational institutions, it actively promotes STEM (Science, Technology, Engineering, and Mathematics) initiatives to cultivate the next generation of engineers and scientists.

Additionally, the factory has established programs that focus on community welfare, including partnerships with local organizations to support health, education, and environmental conservation efforts. This holistic approach to business not only boosts economic growth but also fosters a sense of community and social responsibility.

Looking to the Future

As the global demand for iron powder continues to rise, the Fel Iron Powder Factory is well-positioned to meet this challenge head-on. With ongoing investments in research and development, the factory aims to introduce new products that cater to emerging markets, such as electric vehicles and advanced manufacturing technologies.

Furthermore, the factory is dedicated to continuing its sustainability journey, setting ambitious goals for waste reduction, energy efficiency, and overall environmental performance. By prioritizing both innovation and environmental stewardship, the Fel Iron Powder Factory is paving the way for a more sustainable and prosperous future.

Conclusion

In conclusion, the Fel Iron Powder Factory stands as a testament to what modern manufacturing can achieve when innovation meets responsibility. Through its advanced production methods, commitment to sustainability, and active community engagement, the factory not only produces high-quality iron powder but also contributes positively to the environment and local economy. As industries worldwide seek smarter and greener solutions, the Fel Iron Powder Factory will undoubtedly continue to be a leader in the field, inspiring others to follow in its footsteps.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025