ធ្នូ . 25, 2024 04:05 Back to list

metallurgy precious metals manufacturer

The Role of Metallurgy in Precious Metals Manufacturing

Metallurgy, the science and technology of metals, plays a crucial role in the production and processing of precious metals such as gold, silver, and platinum. As the demand for these metals continues to grow in various sectors, particularly in jewelry and electronics, understanding the intricacies of metallurgy becomes increasingly important. This article delves into the significance of metallurgy in the manufacture of precious metals, discussing the processes, techniques, and advancements that ensure the highest quality products.

The Foundation of Precious Metals Manufacturing

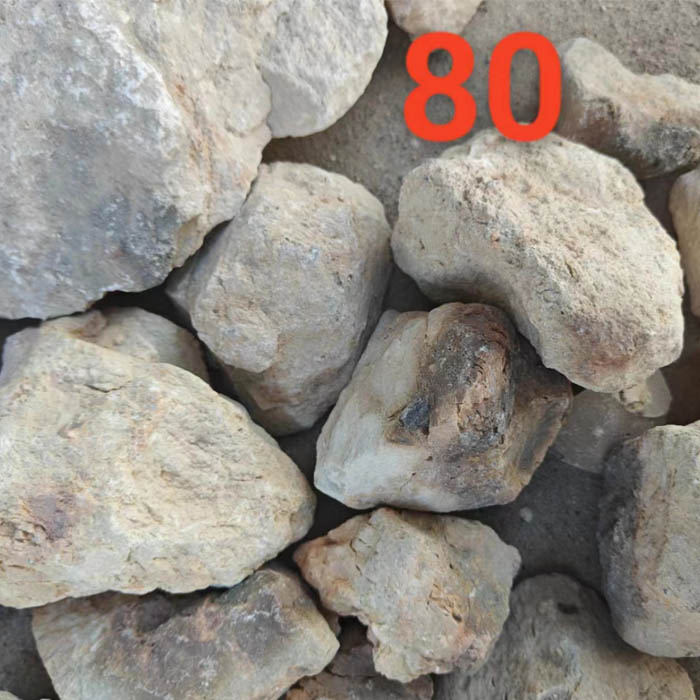

The journey of precious metals begins with mining, where ores are extracted from the earth. These ores primarily contain valuable metals in their elemental forms, often mixed with other minerals. Metallurgy steps in at this point, providing methods to extract and purify these metals. The initial stage involves crushing and grinding the ore to liberate the precious metals, followed by concentration techniques such as flotation or gravity separation to increase the metal content.

Once the ore is concentrated, the next phase is extraction. Two primary methods are employed pyrometallurgy, which uses high temperatures to extract metals, and hydrometallurgy, which uses aqueous solutions to leach metals from their ores. Each method has its advantages and is selected based on factors such as the type of ore, desired purity, and environmental considerations.

Refining and Purification

After extraction, the next vital step in metallurgy is refining. The goal is to elevate the quality of the precious metals to meet industry standards. For gold, for instance, one of the most common refining methods is the Miller process, which involves chlorination to remove impurities, resulting in gold of up to 99.5% purity. This high level of purity is crucial for applications in jewelry and electronics, where even the slightest impurities can affect performance and aesthetic qualities.

Silver, often mixed with copper and other metals, undergoes similar refining processes. Techniques such as electrolysis and chemical leaching are frequently used to attain high-purity silver that can be crafted into various products.

metallurgy precious metals manufacturer

Alloying and Design

Metallurgy does not end with refining; it extends to the alloying and designing of finished products. Precious metals are often alloyed with other metals to enhance their strength, durability, and other desirable properties. For example, gold is frequently alloyed with silver, copper, or palladium to create various karats of gold, ranging from 10K to 24K, each with its own unique characteristics.

In addition to alloying, metallurgy plays a critical role in the design and manufacturing processes of precious metal products. Techniques such as casting, forging, and machining are employed to create intricate designs for jewelry, coins, and electronic components. Advancements in metallurgy, such as the development of new alloys and innovative manufacturing technologies, have not only improved the performance of these products but have also allowed for more complex and aesthetically pleasing designs.

Sustainability Challenges and Innovations

While the metallurgy of precious metals offers numerous benefits, it is not without challenges. The extraction and processing of these metals can have significant environmental impacts, including habitat destruction and pollution. Thus, the industry is continually seeking sustainable practices.

Innovations in metallurgy are focusing on reducing waste, improving energy efficiency, and recycling precious metals from electronic waste. The practice of urban mining, which involves recovering precious metals from discarded electronics, is gaining traction. By applying advanced metallurgical techniques, manufacturers can reclaim valuable resources while minimizing environmental harm.

Conclusion

Metallurgy is a cornerstone of the precious metals manufacturing industry, encompassing everything from extraction to refining, alloying, and design. As technology advances and consumer demands evolve, the role of metallurgy will become even more significant. By promoting sustainable practices and embracing innovation, the industry can ensure that the allure of precious metals continues while also safeguarding the planet for future generations.

-

Environmentally Friendly Granule Covering Agent: Sustainable Solutions

NewsAug.27,2025

-

High Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.26,2025

-

Fe-C Composite Pellets for BOF: Enhance Efficiency, Lower Steelmaking Costs

NewsAug.25,2025

-

Durable Building Material for Round Wall Exporters | Custom Shapes

NewsAug.24,2025

-

Tundish Dry Vibrator: Boost Steel Casting Performance

NewsAug.23,2025

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025