កញ្ញា . 29, 2024 03:42 Back to list

Manufacturers of Heat-Resistant Insulation Materials for Enhanced Energy Efficiency

The Importance of Thermally Insulative Materials A Focus on Factories

In a world where energy efficiency and sustainability are becoming increasingly crucial, the role of thermally insulative materials cannot be overstated. These materials are essential in minimizing heat transfer, which leads to significant energy savings in various applications, ranging from residential buildings to industrial factories. This article will explore the importance of thermally insulative materials in factories, their benefits, types, and the role of manufacturing in advancing these materials.

Factories are often vast structures that require substantial energy for heating and cooling. The energy consumed by HVAC (Heating, Ventilation, and Air Conditioning) systems can be a considerable portion of a factory's operating costs. By utilizing thermally insulative materials, factories can drastically reduce this energy consumption, leading to enhanced efficiency and lower utility bills. This not only increases the factory's profitability but also supports broader environmental objectives by reducing carbon footprints.

The benefits of thermally insulative materials go beyond energy savings. Improved thermal insulation can create a more comfortable working environment for employees. Maintaining stable temperatures within factories can enhance worker productivity, reduce fatigue, and promote safety. For instance, in industries where temperature-sensitive processes or materials are involved, maintaining the right thermal conditions can prevent spoilage and ensure product quality.

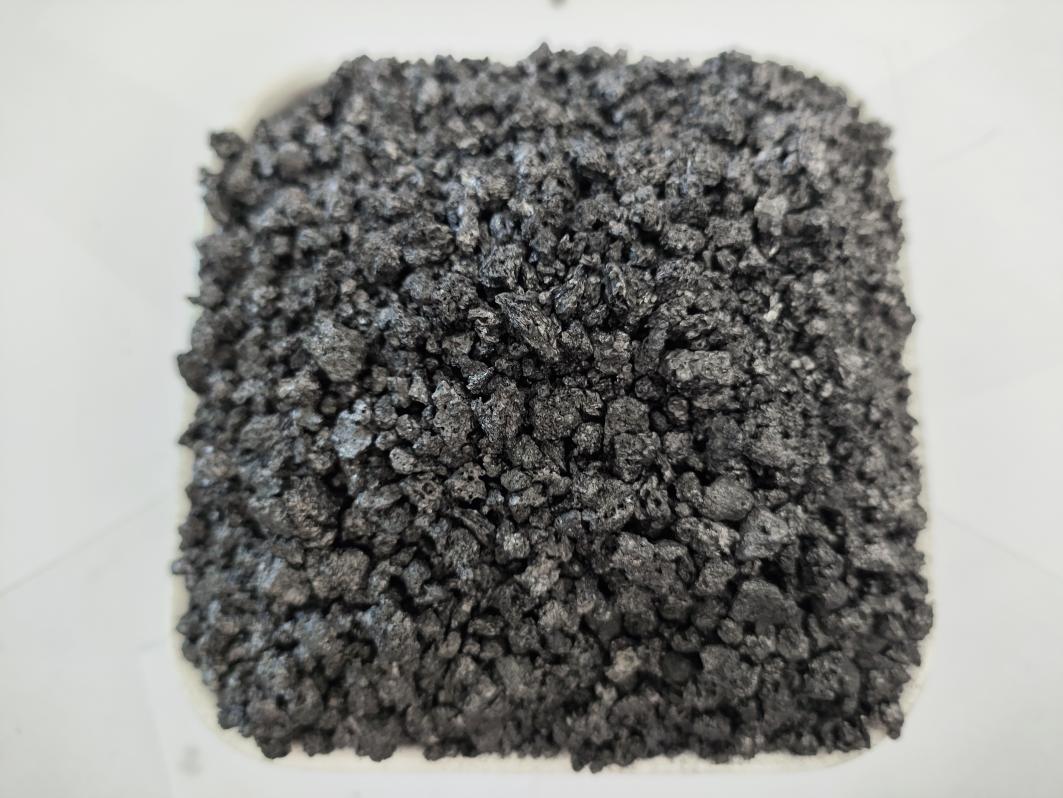

There are various types of thermally insulative materials used in factory construction and refurbishment. Common examples include fiberglass, polyurethane foam, and mineral wool. Each of these materials has specific properties that make them suitable for different applications. For instance, fiberglass is known for its excellent thermal resistance and fire-retardant qualities, while polyurethane foam offers superior insulating performance in a lightweight form. Mineral wool, on the other hand, provides both thermal and acoustic insulation, making it ideal for factories that require reduced noise levels.

thermally insulative materials factories

The manufacturing process of these insulative materials has also evolved considerably. Factories specializing in thermal insulation have embraced innovative technologies to enhance the performance and durability of their products. Advanced manufacturing techniques enable the production of materials that are not only more effective in minimizing heat transfer but are also sustainable and eco-friendly. For example, some companies are now producing insulation materials made from recycled content or developing bio-based alternatives that reduce reliance on non-renewable resources.

In addition to improving thermal performance, leading manufacturers are focused on ensuring that their products are safe and non-toxic. This shift is significant, as safety regulations become more stringent, and there is a growing societal demand for materials that do not pose health risks to factory workers and the environment.

The future of thermally insulative materials in factories looks promising, particularly with the increase in smart manufacturing and the development of sustainable construction practices. As industry trends shift towards smarter energy management systems, the integration of advanced insulation materials can play a vital role. Factories can utilize sensors and IoT technologies to monitor energy usage in real time, enabling them to optimize conditions and maintenance schedules, further enhancing energy efficiency.

In summary, thermally insulative materials are vital in creating energy-efficient, safe, and comfortable factory environments. As manufacturers continue to innovate and improve these materials, the potential for energy savings and environmental benefits will only increase. By investing in quality thermally insulative materials, factories not only improve their operational efficiency but also contribute to a more sustainable future, aligning with global efforts to combat climate change and promote eco-friendly practices.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025