ನವೆಂ . 10, 2024 08:32 Back to list

Top Suppliers of Boiler Refractory Materials for Industrial Applications

Understanding the Role of Boiler Refractory Material Suppliers

In the realm of industrial heating systems, the significance of refractory materials cannot be overstated. These materials are essential in lining and insulating boilers, furnaces, and kilns, serving as a barrier to contain heat effectively while withstanding extreme temperatures. The proper functioning of these systems heavily relies on the quality and reliability of the refractory materials used. Hence, choosing the right boiler refractory material suppliers is vital for industries aiming for efficiency and longevity in their thermal systems.

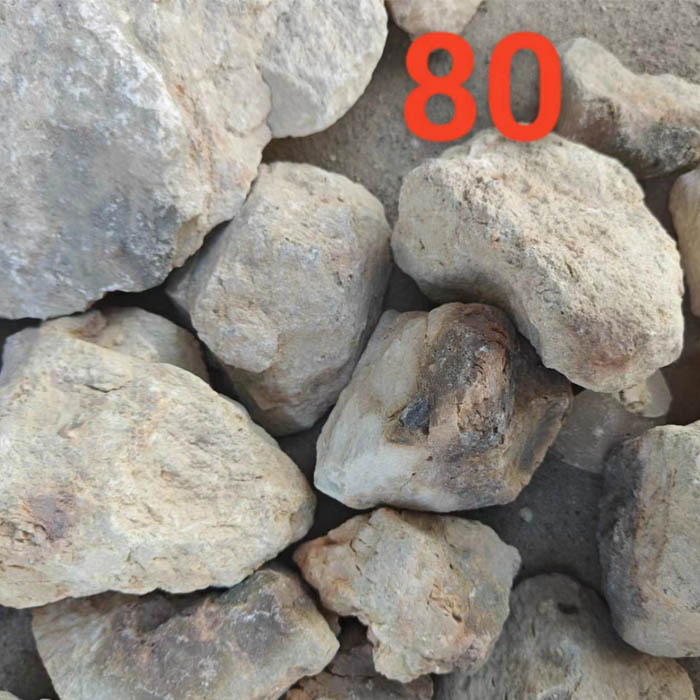

Refractory materials are designed to endure the harsh conditions present within boilers. They must resist not only high temperatures but also chemical corrosion from various combustion processes. Common types of refractory materials used in boiler applications include alumina, silica, and fireclay refractories. Suppliers typically offer a range of products, from bricks and castables to insulation materials and specialty coatings. Each type of material has unique properties suited to different applications and operating conditions.

When seeking out boiler refractory material suppliers, industries should prioritize several key factors. First and foremost, the supplier's reputation is critical. A supplier known for high-quality products and dependable service will ensure that the materials used in boiler linings are durable and effective. Checking for certifications and industry standards compliance can provide insight into the supplier's credibility and commitment to quality.

Moreover, understanding the supplier's technical expertise is equally important. A knowledgeable supplier can provide invaluable support in selecting the right materials for specific applications and offer guidance on installation techniques and maintenance. Technical support may include on-site consultations, which can help identify potential issues before they become significant problems, thus saving time and reducing costs in the long run.

boiler refractory material suppliers

Another factor to consider is the supplier’s ability to customize materials based on unique operational needs. Industries vary greatly in their heating processes, so a one-size-fits-all approach often doesn’t suffice. Suppliers who can offer custom solutions tailored to specific environments and requirements can significantly enhance operational efficiency. This customization may include adjusting the material's thermal conductivity, mechanical strength, or chemical resistance to suit unique circumstances.

Additionally, suppliers should have a robust supply chain to ensure timely delivery of refractory materials. Delays in obtaining necessary materials can lead to operational downtime, which can be costly. A reliable supplier will have a proven track record of meeting deadlines and managing logistics efficiently.

Lastly, consider sustainability practices when selecting boiler refractory material suppliers. As industries become increasingly aware of their environmental impact, suppliers who prioritize sustainable materials and processes may provide a competitive advantage. Using eco-friendly refractories can not only enhance the company’s image but also improve compliance with environmental regulations.

In conclusion, the selection of boiler refractory material suppliers plays a crucial role in the success and efficiency of thermal systems in various industries. By focusing on the supplier’s reputation, technical expertise, customization capabilities, reliability, and sustainability, businesses can make informed choices that will positively impact their operations. Investing in high-quality refractory materials from reputable suppliers is not just a matter of compliance; it is a strategic decision that will ensure operational excellence and longevity. As industry needs evolve, partnering with the right suppliers will become even more critical in navigating the challenges of modern manufacturing and energy production.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025