नोव्हेंबर . 23, 2024 16:46 Back to list

material refractory suppliers

Understanding Material Refractory Suppliers A Critical Component of Industry

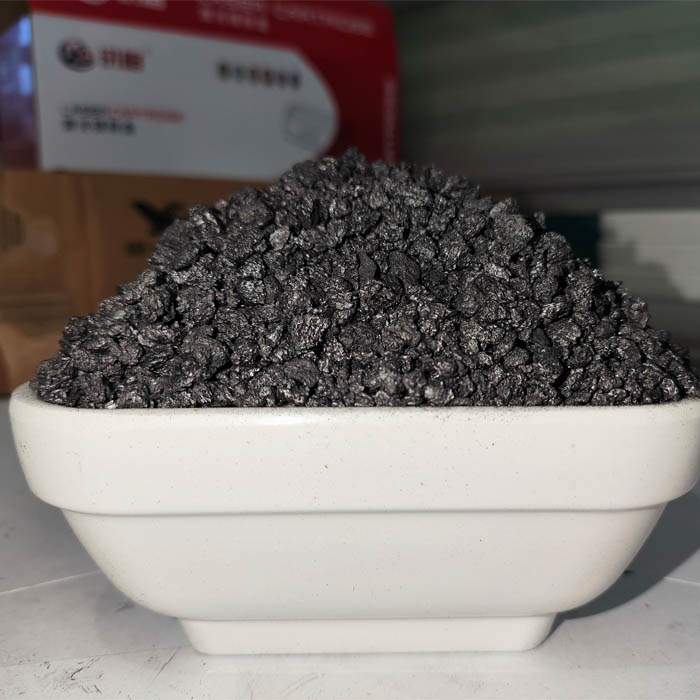

In the world of manufacturing and industrial processes, refractory materials play a crucial role, particularly in high-temperature applications. Refractories are heat-resistant materials that are essential in various operations, including metal production, glass manufacturing, and cement processing. The need for reliable and efficient refractory materials has led to the emergence of specialized suppliers who provide these essential products. This article will explore the significance of refractory suppliers and the factors that influence their role in different industries.

Understanding Material Refractory Suppliers A Critical Component of Industry

The role of refractory suppliers is multifaceted. Firstly, they source raw materials and produce various refractory products, including bricks, castables, and monolithics. They must ensure that their products meet the rigorous standards required for specific applications. Quality control is paramount, as any failure in refractory performance can lead to operational inefficiencies, safety hazards, and significant financial losses for industrial operations.

material refractory suppliers

Choosing the right refractory supplier is crucial. Factors to consider include the supplier's expertise, product range, customization capabilities, and delivery times. Experienced suppliers can provide valuable insights into material selection based on the specific conditions an operation may encounter. For instance, high alumina refractories may be favored in an aluminum production facility due to their superior performance in molten metal applications, while silica refractories may be more suitable for glass production due to their thermal stability.

Furthermore, technological advancements have influenced the refractory supply industry. Innovative manufacturing techniques and the use of advanced materials have led to the development of refractories with enhanced properties. For example, the introduction of nanotechnology in refractory production has resulted in materials that can withstand even higher temperatures and resist chemical corrosion more effectively.

Another significant aspect of refractory suppliers is their commitment to sustainability. As industries strive to reduce their environmental impact, many refractory manufacturers are exploring eco-friendly materials and recycling options for their products. Suppliers that prioritize sustainable practices not only contribute to environmental conservation but also cater to the increasing demand from customers who are now factoring sustainability into their procurement processes.

In summary, material refractory suppliers are an indispensable part of the industrial landscape. Their ability to provide high-quality, reliable, and innovative refractory materials directly impacts the efficiency and safety of high-temperature operations across various industries. As technology evolves and sustainability becomes more critical, suppliers must adapt to meet the changing demands of their customers and uphold the standards necessary for maintaining operational excellence. When selecting a refractory supplier, companies should consider factors such as experience, product variety, quality assurance, and dedication to sustainable practices to ensure they partner with the best in the industry.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025