Jul . 27, 2024 22:57 Back to list

4 Cubic Feet Vermiculite Bag Manufacturing Process and Benefits for Gardening and Construction

Understanding 4% Cubic Ft Bag Vermiculite A Comprehensive Overview of Its Factory Production and Applications

Vermiculite is a naturally occurring mineral known for its unique properties, making it a versatile material used in various industries, particularly in gardening, construction, and insulation. Vermiculite expands when heated, creating lightweight, fire-resistant, and absorbent particles that provide excellent insulation and aeration. In this article, we will delve into the production of vermiculite, specifically focusing on the 4% cubic ft bags used for various applications and the factory processes involved in their manufacture.

What is Vermiculite?

Vermiculite is a hydrated laminar mineral that undergoes significant expansion when heated. Its structure consists of thin, flat particles that can be easily compressed and expanded. This characteristic, combined with its lightweight nature, makes vermiculite an excellent choice for improving soil aeration and drainage in gardening. Additionally, it is used in construction as an insulating material and for fireproofing purposes.

The Factory Production Process

The production of vermiculite begins with the mining of crude ore, which is usually extracted from open-pit mines. The ore is then transported to processing facilities, where it undergoes several stages of refinement

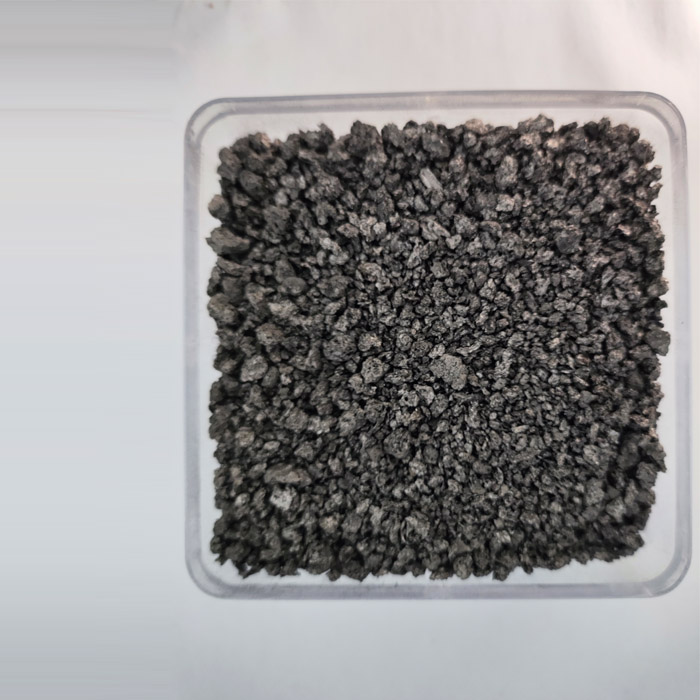

1. Crushing and Screening The crude vermiculite is crushed into smaller pieces using various crushing machines. These pieces are then screened to separate the finer grades suitable for expanded vermiculite production.

2. Heating and Expansion The screened material is subjected to high temperatures (approximately 1,600°F or 870°C) in a process called exfoliation. During this heating, vermiculite granules pop and expand up to 20 times their original size, resulting in a lightweight, fluffy product. This process is crucial in producing vermiculite that can adequately serve its intended purposes.

3. Cooling After exfoliation, the material is cooled and sorted based on particle size. Different sizes may be needed for specific applications, such as horticulture, where coarse particles are beneficial for drainage, and finer particles are advantageous for retaining moisture.

4 cubic ft bag vermiculite factory

4. Packaging The expanded vermiculite is then packaged into bags, typically reaching a volume of 4 cubic feet for easy handling and distribution. Each bag is prepared to ensure that it is durable and can withstand transportation and storage without compromising the quality of the vermiculite inside.

Applications of 4% Cubic Ft Bag Vermiculite

The final product, packaged in 4% cubic ft bags, has a wide range of applications. Here are some key uses

- Gardening and Horticulture Vermiculite is commonly mixed with potting soils to improve aeration, drainage, and moisture retention. It creates an ideal environment for plant roots to grow, ensuring healthy and robust plants.

- Construction Its fire-resistant properties make vermiculite an excellent choice for insulation in residential and commercial buildings. It is also used in lightweight concrete and as a filler material in various construction applications.

- Soundproofing Due to its structure, vermiculite provides effective sound dampening, making it ideal for use in music studios and other spaces where sound control is essential.

- Environmental Applications Vermiculite can absorb water and nutrients, making it beneficial for erosion control, as well as in spill cleanup of hazardous materials due to its absorbent nature.

In conclusion, the 4% cubic ft bag of vermiculite is not just a simple product; it represents a complex production process that underscores the mineral's versatility and utility across various sectors. From enhancing plant growth to providing insulation in buildings, vermiculite remains an essential component in optimizing performance and sustainability in both industrial and environmental applications. As industries continue to evolve, the demand for this remarkable mineral is likely to grow, reinforcing its importance in our daily lives.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025