Jan . 01, 2025 10:28 Back to list

Supplier Selection Process for Adsorb Trial Innovations and Benefits

The Importance of Adsorbent Trials and Supplier Selection

In the realm of industrial processes, adsorbents play a crucial role in separation and purification techniques. Whether in water treatment, gas purification, or chemical production, the selection of an appropriate adsorbent is vital. The effectiveness of these materials often hinges not just on their inherent properties, but also on the quality and reliability of the suppliers that provide them. This article delves into the significance of adsorbent trials and the factors to consider when selecting a supplier.

Understanding Adsorbents

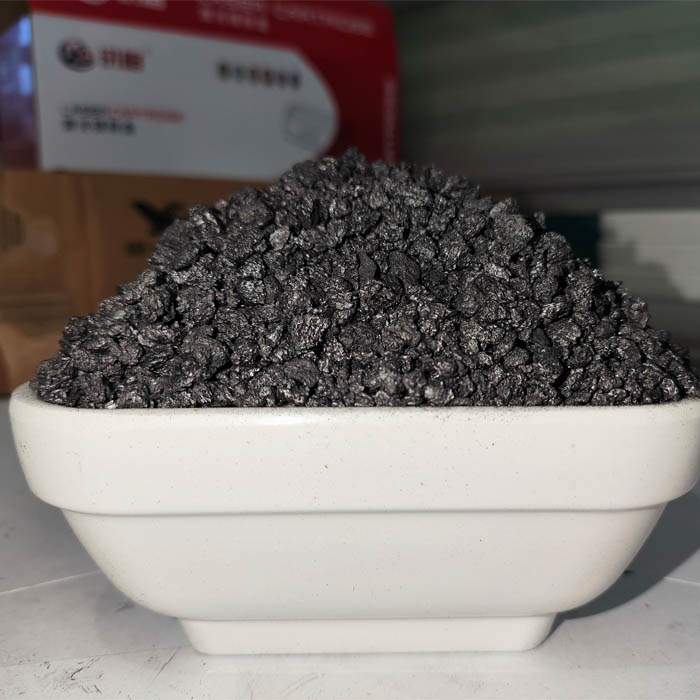

Adsorbents are materials that adhere to molecules or particles from gases or liquids through physical or chemical reactions. Common examples include activated carbon, silica gel, zeolites, and activated alumina. Each type of adsorbent presents unique characteristics that make it suitable for specific applications. Choosing the right adsorbent requires understanding the nature of the target substance, operational conditions, and the desired purity levels.

The Role of Adsorbent Trials

Before finalizing the choice of an adsorbent, conducting trials is essential. These trials help determine how well a candidate material performs under specific conditions related to the intended application. In these trials, variables such as temperature, pressure, concentration, and flow rates are manipulated to simulate actual operational environments.

Through these tests, organizations can assess crucial factors such as - Capacity The amount of substance that can be adsorbed by the material. - Selectivity The ability of the adsorbent to preferentially adsorb certain compounds over others. - Kinetics The rate at which adsorption occurs, which affects the overall efficiency of the process. - Regeneration The ease with which the adsorbent can be reused after saturation.

Successful adsorbent trials yield valuable data that inform decision-making and optimize process design. They can lead to enhanced performance, cost savings, and sustainability.

Selecting the Right Supplier

adsorb trial supplier

Once suitable adsorbents are identified through trials, the next step is to select a reliable supplier. Supplier selection is pivotal, as the performance of an adsorbent is also tied to its quality and consistency. Here are critical factors to consider when evaluating potential suppliers

1. Quality Assurance Suppliers should adhere to stringent quality control measures throughout the production process. Certifications such as ISO 9001 can indicate a supplier's commitment to quality.

2. Technical Support A reputable supplier should provide technical assistance, including guidance on selecting the right adsorbent for specific applications and troubleshooting support.

3. Reputation and Experience Suppliers with a strong track record and industry experience are generally more trustworthy. Customer testimonials and case studies can offer insights into their reliability and capabilities.

4. Availability and Lead Time Timely availability of products is crucial for maintaining operational efficiency. Suppliers should have a clear and manageable supply chain.

5. Cost and Value Competitive pricing is important, but it should not come at the expense of quality. Evaluate the total cost of ownership, which includes purchase price, longevity, and efficiency of the adsorbent.

6. Sustainability Practices In today’s environmentally conscious world, choosing suppliers that prioritize sustainability in their sourcing and production processes can align with corporate social responsibility goals.

Conclusion

Adsorbent trials and supplier selection are integral components in optimizing industrial processes involving adsorption. Conducting thorough trials not only ensures the effectiveness of the adsorbent selected but also highlights the importance of collaborating with a capable and trustworthy supplier. By considering various factors—quality assurance, technical support, reputation, availability, cost, and sustainability—organizations can make informed decisions that enhance performance and contribute to the overall success of their operations. The right combination of adsorbents and suppliers can lead to innovations in efficiency, quality, and environmental responsibility, ultimately benefiting both businesses and the planet.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025