Nov . 22, 2024 04:15 Back to list

aggregates for lightweight concrete exporters

Aggregates for Lightweight Concrete Exporters

Lightweight concrete has gained immense popularity in the construction industry due to its numerous advantages, including reduced structural load, improved thermal insulation, and enhanced fire resistance. At the core of lightweight concrete is the choice of aggregates, which directly influence the material's properties. The role of aggregates in the production of lightweight concrete is crucial, particularly for exporters who cater to global demand.

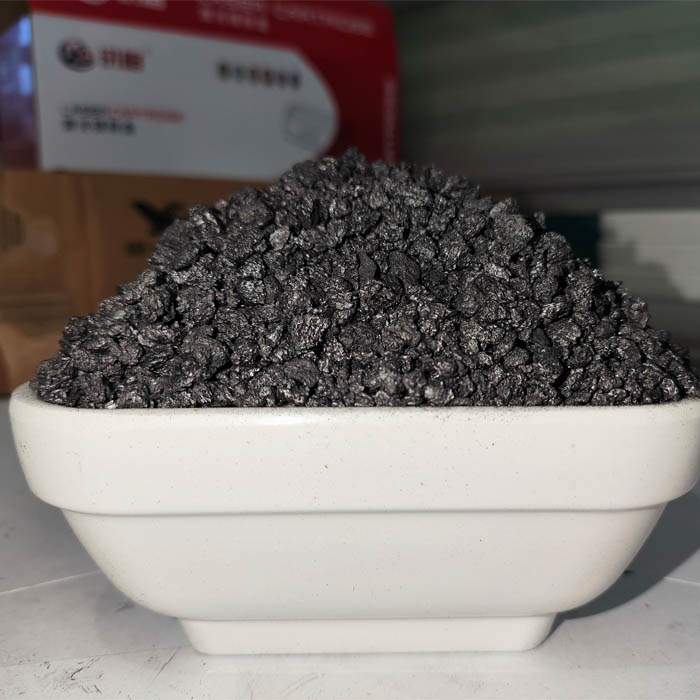

Lightweight aggregates can be derived from various materials and naturally occurring substances. The most common types include expanded clay, expanded shale, expanded glass, and pumice. These aggregates are characterized by their reduced density compared to traditional aggregates like gravel and sand. The lightweight nature of these materials not only contributes to the overall weight reduction of concrete structures but also provides superior insulation properties, making them ideal for a range of construction applications.

The global market for lightweight concrete aggregates has expanded significantly, driven by the construction industry's ever-increasing need for sustainable materials. Exporters must source high-quality lightweight aggregates that meet international standards. The characteristics that define high-quality aggregates include low density, high specific surface area, and good physical and chemical stability. These properties are essential in ensuring that the lightweight concrete produced is durable, strong, and compliant with various construction regulations.

aggregates for lightweight concrete exporters

One of the significant challenges for exporters is ensuring a consistent supply of lightweight aggregates. Sourcing materials domestically can be beneficial, but many exporters look to establish international networks to reduce costs and enhance product offerings. This involves navigating regulatory environments and tariffs, which can significantly impact the feasibility of long-distance shipping. Sustainable practices in the acquisition and shipping of aggregates are increasingly becoming a priority, as companies strive to meet environmental regulations and reduce their carbon footprints.

In terms of applications, lightweight concrete is ideal for various construction projects, including residential buildings, commercial complexes, and infrastructure works like bridges and roads. It is particularly valuable in areas where soil conditions require lighter construction materials to reduce loading stresses. Its insulating properties also make it a popular choice in regions with extreme climates, as it helps maintain indoor temperatures, thereby reducing energy costs.

Moreover, as the construction industry seeks to innovate and adopt greener practices, lightweight concrete offers a promising solution. For instance, the incorporation of recycled materials, such as recycled aggregates from construction and demolition waste, into lightweight concrete mixes can significantly lower environmental impact. This trend is not only appealing to eco-conscious consumers but also aligns with global sustainability goals. Exporters who invest in research and development to create innovative lightweight aggregate solutions stand to gain a competitive edge in the marketplace.

In summary, aggregates play a pivotal role in the production of lightweight concrete for exporters. By understanding the properties and types of lightweight aggregates, maintaining consistent quality, and navigating the complexities of international trade, exporters can effectively meet the growing demand for lightweight concrete. With the ongoing emphasis on sustainability and innovation in construction, the future of lightweight concrete aggregates looks promising, presenting new opportunities for exporters to expand their reach while contributing to a more sustainable built environment. As the market continues to evolve, adaptability and a commitment to quality will be crucial for success in this dynamic industry.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025