Nov . 09, 2024 03:41 Back to list

Manufacturers of Alta CB 65 Slate Graphite for High-Performance Applications

Understanding the Alta CB 65 Slate Graphite A Leap in Manufacturing Technology

In the world of materials, graphite has long been recognized for its unique properties, including high thermal and electrical conductivity, chemical stability, and excellent lubricity. Among its various forms, slate graphite has emerged as a sought-after option for many industrial applications. The Alta CB 65 slate graphite is a prime example of innovation in this field, and understanding its manufacturing process and properties sets the stage for its wide-ranging applications.

The Composition and Structure of Alta CB 65 Slate Graphite

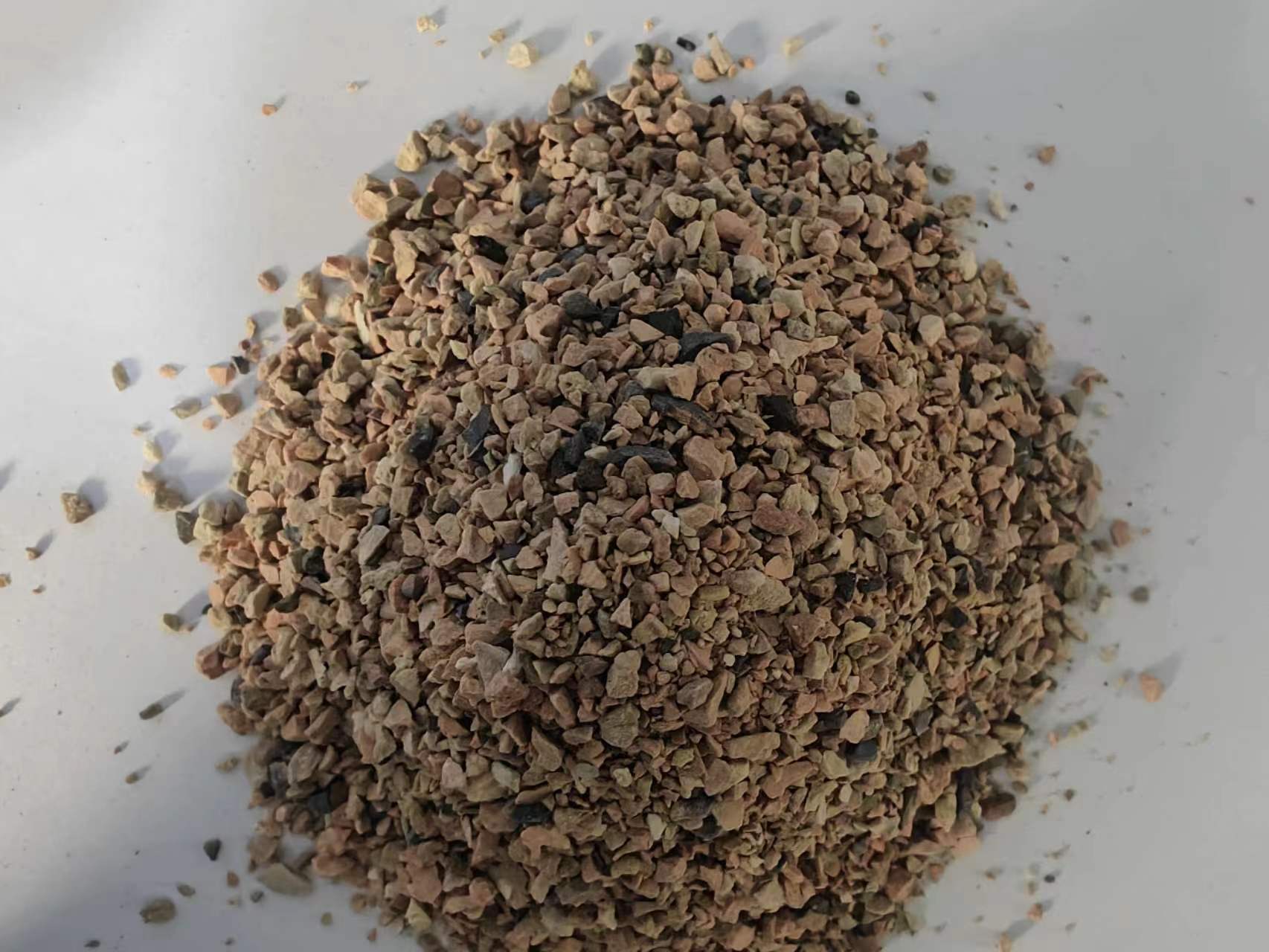

Alta CB 65 slate graphite is derived from high-quality natural graphite, which undergoes a meticulous transformation process. This unique slate graphite combines the flaky structure of natural graphite with enhancements that optimize its characteristics for specific applications. Its composition typically consists of a varying degree of carbon content, often exceeding 90%. The distinctive layered structure allows for easier intercalation, making it highly suitable for electronic applications.

The manufacturing process begins by sourcing high-purity graphite from trusted suppliers. The raw material is then subjected to various mechanical and chemical treatments to enhance its properties. This may include processes like crushing, grinding, and purification, followed by the application of heat to achieve optimal characteristics.

Key Benefits of Alta CB 65 Slate Graphite

One of the most significant advantages of Alta CB 65 slate graphite is its exceptional thermal and electrical conductivity. This makes it a preferred choice in applications where efficient heat dissipation is critical, such as in batteries and electronic components. The material’s excellent lubricating properties also make it ideal for applications in machinery, lubricants, and automotive components where reduced friction is essential.

The chemical inertness of slate graphite adds another dimension to its utility

. It doesn’t react with most chemicals, rendering it suitable for use in harsh environments. This aspect ensures longevity and reliability, particularly for industries such as aerospace, automotive, and electronics.alta cb 65 slate graphite manufacturers

Manufacturing Techniques and Quality Control

To maintain the high standards expected of Alta CB 65 slate graphite, manufacturers implement rigorous quality control measures throughout the production process. Advanced technologies, such as X-ray diffraction and scanning electron microscopy, are employed to analyze particle size distribution and purity levels. This scrutiny ensures that the final product meets the stringent requirements of various industries.

Furthermore, manufacturers often utilize environmentally friendly practices during production. These sustainable methods minimize waste and reduce carbon footprints, aligning with global trends toward eco-friendly manufacturing.

Applications and Market Trends

Alta CB 65 slate graphite is making waves in various industries, primarily in the field of electronics. Its use in lithium-ion batteries is particularly noteworthy, as it enhances energy performance and extends battery life. Additionally, it is increasingly applied in fuel cell technologies and other renewable energy systems.

The demand for slate graphite is projected to grow significantly in the coming years, driven by the expansion of electric vehicles and advancements in energy storage technologies. As industries continue to seek robust and reliable materials, the versatility of Alta CB 65 slate graphite positions it as a key player in the market.

Conclusion

In conclusion, Alta CB 65 slate graphite represents a significant advancement in manufacturing technology. Its unique properties, derived from high-quality natural graphite, make it an indispensable material across multiple sectors, including electronics, automotive, and aerospace. As manufacturers strive to meet the increasing demand for efficiency and sustainability, the continued innovation in the production of Alta CB 65 slate graphite will undoubtedly shape the future of many industries. With its multifaceted applications and impressive performance characteristics, it is clear that slate graphite is not just a material of the moment, but a cornerstone for advancements in technology and industrial development.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025