Jun . 14, 2024 06:07 Back to list

Basic Oxygen Steel Making Suppliers

Basic Oxygen Steelmaking Suppliers A Comprehensive Guide

In the realm of steel production, the process of basic oxygen steelmaking (BOS) holds a significant position. This method, also known as the Linz-Donawitz (L-D) process, is widely used due to its efficiency and cost-effectiveness. To ensure the smooth operation of this process, it is crucial to source high-quality raw materials and equipment from reliable suppliers. In this article, we will delve into the world of basic oxygen steelmaking suppliers, exploring their roles, capabilities, and how they contribute to the steel industry.

Role of Basic Oxygen Steelmaking Suppliers

Suppliers play a vital role in the steel industry by providing the necessary raw materials, equipment, and services required for basic oxygen steelmaking. These suppliers ensure that steel manufacturers have access to the highest quality products and technologies, which in turn leads to the production of high-performance steel.

Capabilities of Basic Oxygen Steelmaking Suppliers

When it comes to basic oxygen steelmaking suppliers, there are several key capabilities that set them apart. These include

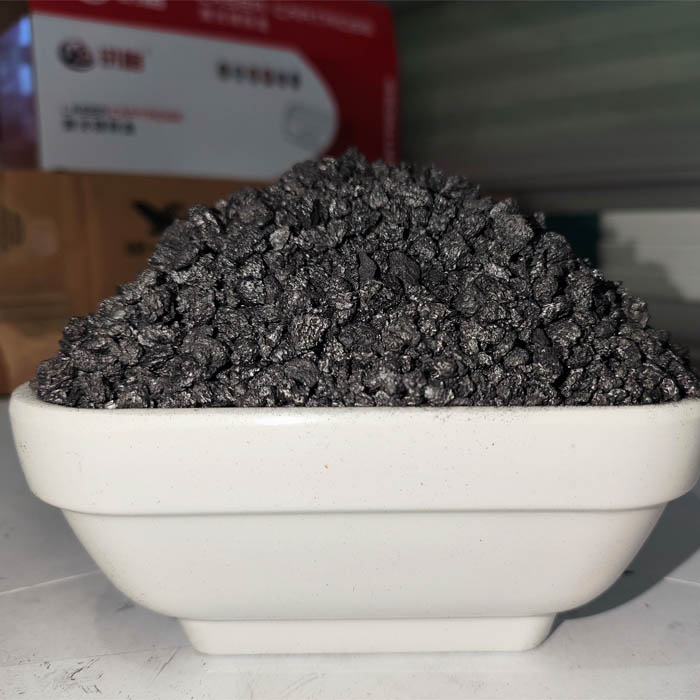

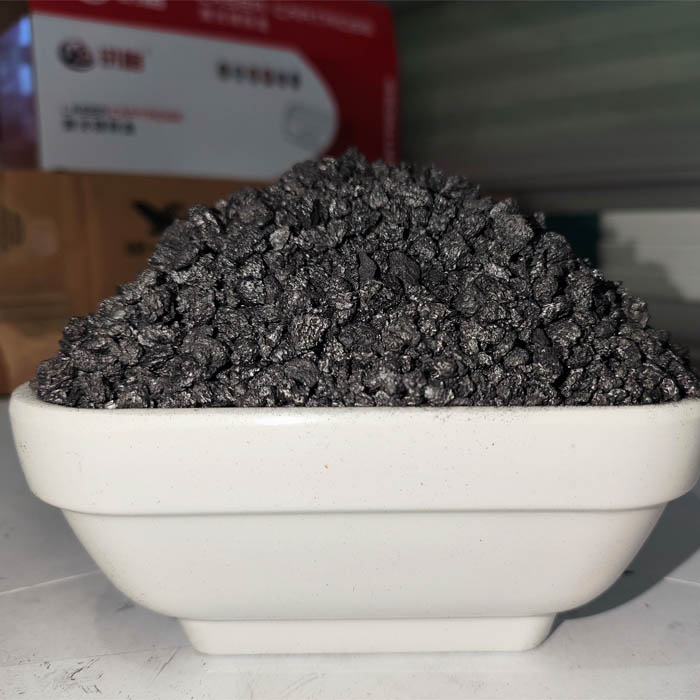

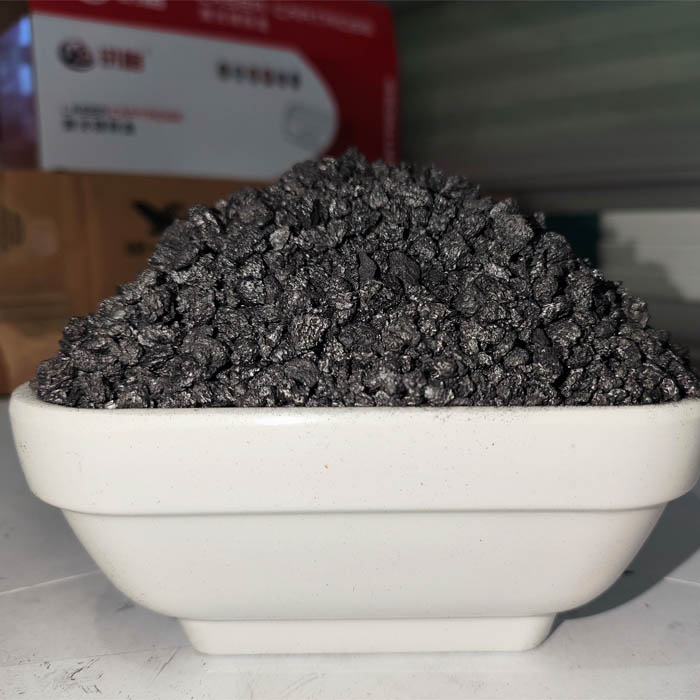

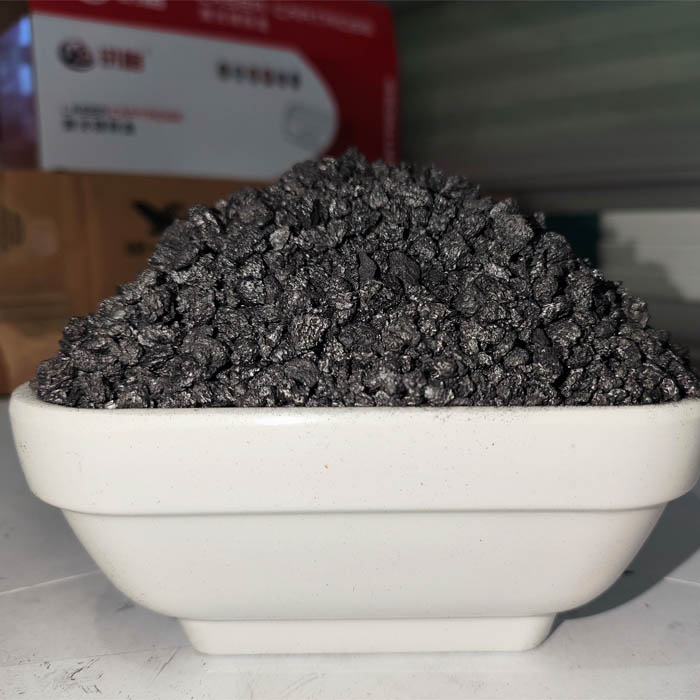

1. Product Range Suppliers must offer a wide range of products, including scrap metal, refractories, oxygen, and other essential materials and equipment. This ensures that steel manufacturers can find everything they need under one roof.

2. Quality Assurance Basic oxygen steelmaking requires high-quality raw materials and equipment to produce steel with the desired properties. Therefore, suppliers must implement strict quality control measures to ensure that all products meet international standards.

3. Technical Support Steel manufacturers rely on suppliers for technical expertise and support Technical Support Steel manufacturers rely on suppliers for technical expertise and support Technical Support Steel manufacturers rely on suppliers for technical expertise and support Technical Support Steel manufacturers rely on suppliers for technical expertise and support

Technical Support Steel manufacturers rely on suppliers for technical expertise and support Technical Support Steel manufacturers rely on suppliers for technical expertise and support basic oxygen steel making suppliers. Suppliers should be able to provide guidance on process optimization, troubleshooting, and other technical issues to help manufacturers achieve optimal performance.

4. Logistics and Distribution Efficient logistics and distribution networks are critical for ensuring that raw materials and equipment reach steel manufacturers on time. Suppliers should have robust logistical capabilities to handle large volumes of goods and deliver them to customers worldwide.

How Basic Oxygen Steelmaking Suppliers Contribute to the Industry

Basic oxygen steelmaking suppliers play a crucial role in the development and growth of the steel industry. By providing high-quality products and services, suppliers enable steel manufacturers to produce steel more efficiently and cost-effectively. This, in turn, drives innovation and competition within the industry, leading to the development of new steel products and applications.

Moreover, suppliers contribute to the sustainability of the steel industry by promoting the use of recycled materials and energy-efficient technologies. This helps to reduce the environmental impact of steel production and promote a more sustainable future for the industry.

Conclusion

In conclusion, basic oxygen steelmaking suppliers play a vital role in the steel industry by providing the necessary raw materials, equipment, and services required for the L-D process. With their expertise in product range, quality assurance, technical support, and logistics, these suppliers enable steel manufacturers to produce high-performance steel efficiently and cost-effectively. As the steel industry continues to evolve, the role of suppliers will become increasingly important, driving innovation and sustainability in the sector.

basic oxygen steel making suppliers. Suppliers should be able to provide guidance on process optimization, troubleshooting, and other technical issues to help manufacturers achieve optimal performance.

4. Logistics and Distribution Efficient logistics and distribution networks are critical for ensuring that raw materials and equipment reach steel manufacturers on time. Suppliers should have robust logistical capabilities to handle large volumes of goods and deliver them to customers worldwide.

How Basic Oxygen Steelmaking Suppliers Contribute to the Industry

Basic oxygen steelmaking suppliers play a crucial role in the development and growth of the steel industry. By providing high-quality products and services, suppliers enable steel manufacturers to produce steel more efficiently and cost-effectively. This, in turn, drives innovation and competition within the industry, leading to the development of new steel products and applications.

Moreover, suppliers contribute to the sustainability of the steel industry by promoting the use of recycled materials and energy-efficient technologies. This helps to reduce the environmental impact of steel production and promote a more sustainable future for the industry.

Conclusion

In conclusion, basic oxygen steelmaking suppliers play a vital role in the steel industry by providing the necessary raw materials, equipment, and services required for the L-D process. With their expertise in product range, quality assurance, technical support, and logistics, these suppliers enable steel manufacturers to produce high-performance steel efficiently and cost-effectively. As the steel industry continues to evolve, the role of suppliers will become increasingly important, driving innovation and sustainability in the sector.

Technical Support Steel manufacturers rely on suppliers for technical expertise and support Technical Support Steel manufacturers rely on suppliers for technical expertise and support

Technical Support Steel manufacturers rely on suppliers for technical expertise and support Technical Support Steel manufacturers rely on suppliers for technical expertise and support basic oxygen steel making suppliers. Suppliers should be able to provide guidance on process optimization, troubleshooting, and other technical issues to help manufacturers achieve optimal performance.

4. Logistics and Distribution Efficient logistics and distribution networks are critical for ensuring that raw materials and equipment reach steel manufacturers on time. Suppliers should have robust logistical capabilities to handle large volumes of goods and deliver them to customers worldwide.

How Basic Oxygen Steelmaking Suppliers Contribute to the Industry

Basic oxygen steelmaking suppliers play a crucial role in the development and growth of the steel industry. By providing high-quality products and services, suppliers enable steel manufacturers to produce steel more efficiently and cost-effectively. This, in turn, drives innovation and competition within the industry, leading to the development of new steel products and applications.

Moreover, suppliers contribute to the sustainability of the steel industry by promoting the use of recycled materials and energy-efficient technologies. This helps to reduce the environmental impact of steel production and promote a more sustainable future for the industry.

Conclusion

In conclusion, basic oxygen steelmaking suppliers play a vital role in the steel industry by providing the necessary raw materials, equipment, and services required for the L-D process. With their expertise in product range, quality assurance, technical support, and logistics, these suppliers enable steel manufacturers to produce high-performance steel efficiently and cost-effectively. As the steel industry continues to evolve, the role of suppliers will become increasingly important, driving innovation and sustainability in the sector.

basic oxygen steel making suppliers. Suppliers should be able to provide guidance on process optimization, troubleshooting, and other technical issues to help manufacturers achieve optimal performance.

4. Logistics and Distribution Efficient logistics and distribution networks are critical for ensuring that raw materials and equipment reach steel manufacturers on time. Suppliers should have robust logistical capabilities to handle large volumes of goods and deliver them to customers worldwide.

How Basic Oxygen Steelmaking Suppliers Contribute to the Industry

Basic oxygen steelmaking suppliers play a crucial role in the development and growth of the steel industry. By providing high-quality products and services, suppliers enable steel manufacturers to produce steel more efficiently and cost-effectively. This, in turn, drives innovation and competition within the industry, leading to the development of new steel products and applications.

Moreover, suppliers contribute to the sustainability of the steel industry by promoting the use of recycled materials and energy-efficient technologies. This helps to reduce the environmental impact of steel production and promote a more sustainable future for the industry.

Conclusion

In conclusion, basic oxygen steelmaking suppliers play a vital role in the steel industry by providing the necessary raw materials, equipment, and services required for the L-D process. With their expertise in product range, quality assurance, technical support, and logistics, these suppliers enable steel manufacturers to produce high-performance steel efficiently and cost-effectively. As the steel industry continues to evolve, the role of suppliers will become increasingly important, driving innovation and sustainability in the sector. Next:

Latest news

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025