Nov . 11, 2024 08:23 Back to list

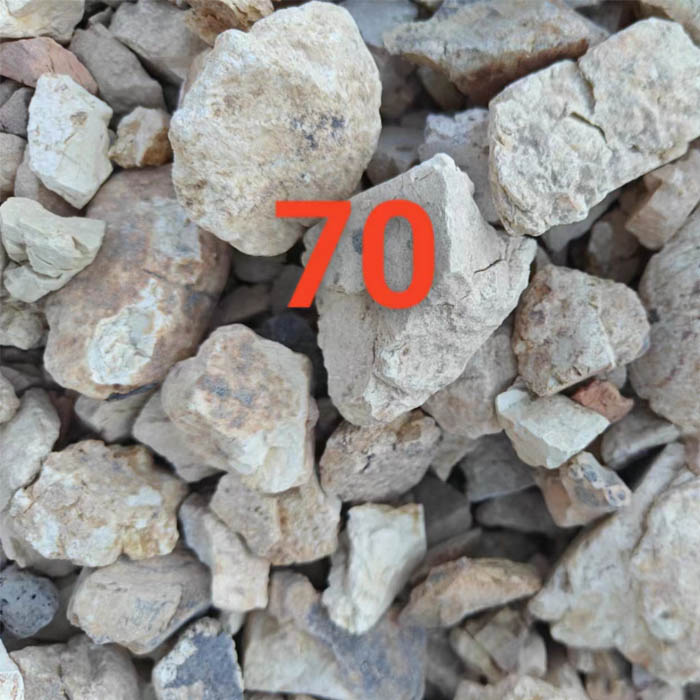

boiler refractory materials

Understanding Boiler Refractory Materials Essential for Thermal Efficiency and Durability

Boilers play a critical role in various industries, generating steam for power, heating, and various processing applications. To ensure optimal performance and longevity, the materials used within their construction must withstand extreme conditions, including high temperatures, corrosive environments, and thermal shock. This is where refractory materials come into play.

Refractory materials are specialized substances that can withstand heat and are resistant to wear, corrosion, and other forms of physical and chemical degradation. They are essential for the effective operation of boilers, as they line the furnace and combustion chamber, providing both insulation and protection to the structural components of the boiler.

The primary function of boiler refractory materials is to maintain the correct temperature within the boiler while minimizing heat loss. This thermal insulation is vital, as it enhances the overall efficiency of the boiler. By keeping the heat contained within the furnace, the energy generated through combustion is maximized, leading to better fuel economy and reduced operational costs.

There are several types of refractory materials used in boiler applications, each with unique properties suited to specific conditions. Common types include

1. Silica Refractories These are composed primarily of silicon dioxide and are known for their excellent resistance to thermal shock. Silica refractories are widely used in high-temperature furnace linings due to their ability to withstand abrupt temperature changes.

2. Alumina Refractories These contain alumina and offer higher durability and resistance to high temperatures compared to silica refractories. Alumina-based materials are often utilized in high-efficiency systems, where advanced thermal management is crucial.

boiler refractory materials

3. Magnesite Refractories Made from magnesium oxide, these refractories are particularly effective in steelmaking and other high-temperature environments. They provide excellent resistance to basic slags and are ideal for applications involving metal production.

4. Ceramic Fiber Lightweight and highly insulating, ceramic fiber refractories are increasingly popular for their ease of installation and high energy efficiency. They can withstand high temperatures and are often used in conjunction with other refractory materials.

In addition to high-temperature resistance and thermal insulation, boiler refractory materials must exhibit mechanical strength, resistance to corrosion and oxidation, and low porosity. These properties ensure that the materials maintain their integrity under the intense conditions typical of boiler operations.

The selection of appropriate refractory materials is vital for the longevity and safety of boiler systems. Improper choices can lead to premature wear and failure, resulting in costly repairs or even catastrophic incidents. Therefore, it is essential for engineers and operators to understand the specific operational conditions of their boilers and select refractory materials accordingly.

Regular maintenance and monitoring of refractory linings are also crucial. Over time, even the best materials can degrade due to high thermal cycles and exposure to aggressive flue gases. Scheduled inspections and timely repairs or replacements help maintain boiler efficiency, reduce downtime, and ensure operational safety.

In conclusion, boiler refractory materials are a fundamental component in the design and operation of efficient and durable boilers. By choosing the right materials and maintaining them properly, industries can enhance their thermal efficiency, reduce operational costs, and prolong the lifespan of their boiler systems. As technology continues to advance, further innovations in refractory materials are likely to emerge, leading to even more effective solutions for high-temperature industrial applications.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025