Dec . 07, 2024 04:19 Back to list

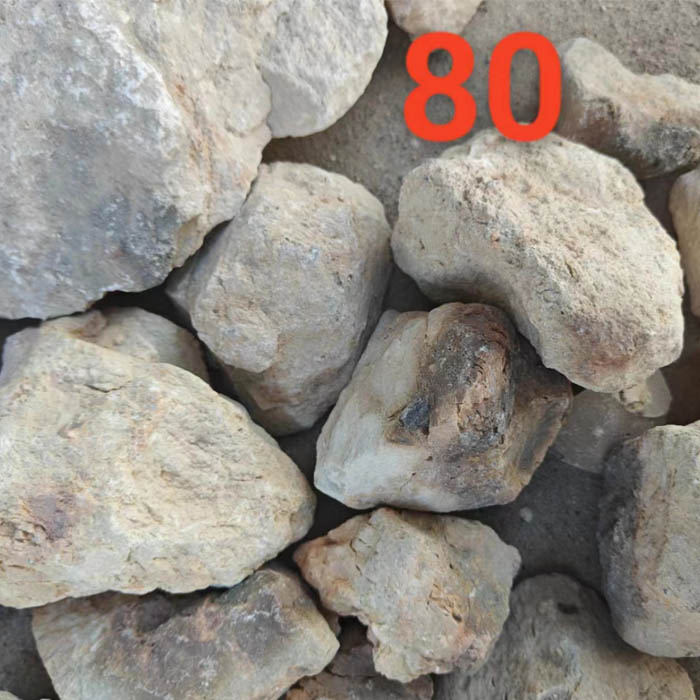

carbon powder factory

The Rise of Carbon Powder Factories A Sustainable Approach to Material Production

In recent years, the demand for carbon-based materials has surged, driven by advancements in technology and a growing focus on sustainability. Carbon powder, a key material used in various industries including electronics, batteries, and even cosmetics, has gained significant attention. The establishment of carbon powder factories is becoming increasingly popular as companies look to harness the potential of this versatile substance while also addressing environmental concerns.

Carbon powder is derived from various feedstocks, including coal, biomass, and recycled materials. The process typically involves heating these materials in the absence of oxygen, a method known as pyrolysis. This process not only converts the feedstock into carbon powder but also generates useful by-products such as syngas, which can be used as an energy source. As a result, carbon powder factories can significantly contribute to a circular economy by utilizing waste materials and minimizing environmental impact.

The Rise of Carbon Powder Factories A Sustainable Approach to Material Production

Moreover, the construction industry is also experiencing a shift towards using carbon powder. Innovations in concrete technology have led to the incorporation of carbon powder as a supplemental cementitious material. By doing so, manufacturers can reduce the overall carbon footprint of concrete production, addressing one of the largest sources of greenhouse gas emissions in the construction sector. The integration of carbon powder not only improves the material properties of concrete but also promotes the use of recycled materials, further advancing sustainability goals.

carbon powder factory

However, while the benefits of carbon powder factories are compelling, there are challenges that must be addressed. The production process requires significant energy input, which can lead to a large carbon footprint if derived from fossil fuels. To overcome this, many factories are investing in renewable energy sources such as solar, wind, or biomass energy. By utilizing clean energy, these facilities can minimize their environmental impact and align with global sustainability initiatives.

Moreover, as the industry evolves, regulatory frameworks are also adapting to ensure that carbon powder production meets environmental standards. Governments and international organizations are establishing guidelines and certifications to encourage responsible production practices. This regulatory support is crucial in promoting transparency and accountability within the carbon powder supply chain.

The future of carbon powder factories looks promising. With technological advancements and increased awareness of sustainability, these facilities are well-positioned to play a vital role in the materials industry. Innovations in production processes and a focus on recycling feedstocks will further enhance the viability of carbon powder as a sustainable option.

In conclusion, carbon powder factories represent a significant development in the effort to create sustainable materials. By harnessing the potential of carbon powder, industries can reduce reliance on non-renewable resources and minimize environmental impacts. As we move towards a more sustainable future, the continued growth and innovation within the carbon powder sector will be vital in driving the transition to a greener economy. The strategic implementation of renewable energy and adherence to environmental standards will ultimately ensure that carbon powder remains a key player in sustainable manufacturing practices.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025