Jan . 09, 2025 10:52 Back to list

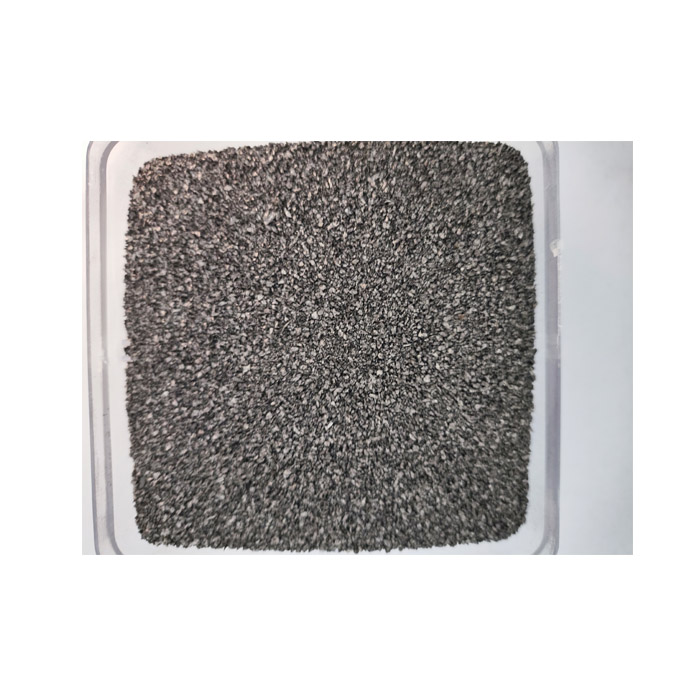

carbon petroleum coke exporters

In the ever-evolving industrial landscape, carbon raisers have proven indispensable. These high-carbon content materials are specifically engineered to elevate the carbon levels in molten steel and iron, thereby enhancing the material's overall quality and performance. As industrial operations become increasingly sophisticated, the demand for premium carbon raisers has never been more crucial, underscoring the vital role they play in achieving optimal metallurgy.

Achieving authoritativeness in the domain of carbon raisers involves a commitment to continual research and innovation. Leading manufacturers invest heavily in the development of carbon raisers with enhanced performance characteristics, such as improved dissolution rates and lower sulfur content. These innovations foster trust and credibility, as industries increasingly seek partners that deliver not just products, but solutions. Trustworthiness is further cemented by adhering to stringent environmental standards. The production of carbon raisers is no longer about output alone but also about sustainable practices that minimize environmental impact. By leveraging cutting-edge technology and adhering to ethical practices, producers affirm their dedication to not just industrial advancement but also ecological preservation. In conclusion, carbon raisers are essential not only to elevate the quality of metal production but also as a testament to industrial growth that values precision, expertise, and sustainability. Companies that understand and implement the latest innovations in carbon raiser technology position themselves as leaders in the metallurgical field. These entities are not only suppliers but strategic partners in industrial success, ensuring that the future of metallurgy is both bright and sustainable.

Achieving authoritativeness in the domain of carbon raisers involves a commitment to continual research and innovation. Leading manufacturers invest heavily in the development of carbon raisers with enhanced performance characteristics, such as improved dissolution rates and lower sulfur content. These innovations foster trust and credibility, as industries increasingly seek partners that deliver not just products, but solutions. Trustworthiness is further cemented by adhering to stringent environmental standards. The production of carbon raisers is no longer about output alone but also about sustainable practices that minimize environmental impact. By leveraging cutting-edge technology and adhering to ethical practices, producers affirm their dedication to not just industrial advancement but also ecological preservation. In conclusion, carbon raisers are essential not only to elevate the quality of metal production but also as a testament to industrial growth that values precision, expertise, and sustainability. Companies that understand and implement the latest innovations in carbon raiser technology position themselves as leaders in the metallurgical field. These entities are not only suppliers but strategic partners in industrial success, ensuring that the future of metallurgy is both bright and sustainable.

Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025