Dec . 25, 2024 11:10 Back to list

Supplier of High-Performance Castable Refractory Materials for Various Industries

The Importance of Choosing the Right Castable Refractory Material Supplier

In industries that rely on high-temperature processes, such as metalworking, glass production, and ceramics, castable refractory materials play a vital role. These materials, designed to withstand extreme heat, provide essential protection to furnaces, kilns, and other thermal equipment. As the demand for reliable performance and durability increases, selecting the right castable refractory material supplier becomes crucial for ensuring operational efficiency and safety.

Understanding Castable Refractory Materials

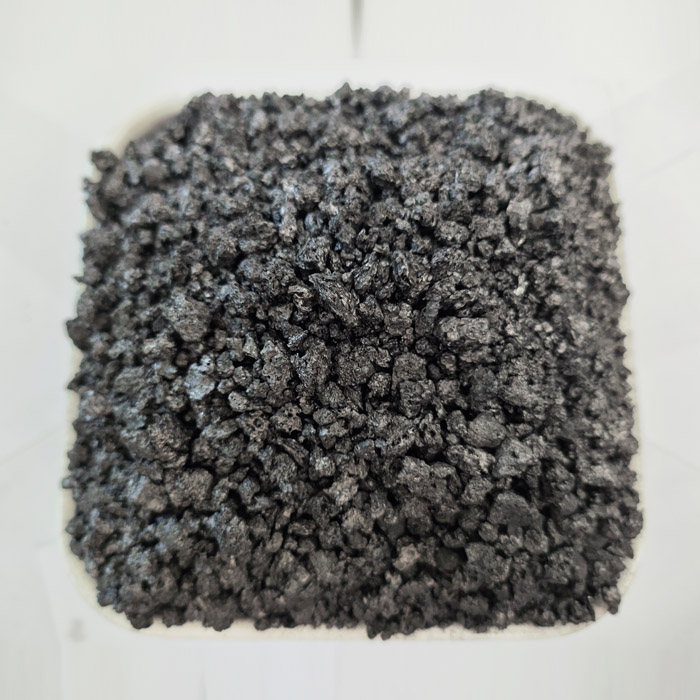

Castable refractories are a type of heat-resistant material that can be shaped and installed in various forms. Unlike traditional bricks, which are rigid and limited to specific shapes, castables can be poured into molds or formed on-site. This versatility allows for customized applications in industrial settings. Made from a mixture of aggregate, bonding agents, and additives, these materials are specifically engineered to withstand high temperatures, thermal shock, and abrasive environments.

Why Supplier Selection Matters

Selecting a supplier for castable refractory materials is not a decision to be taken lightly. The quality of the materials will directly impact the longevity and efficiency of your operations. A reputable supplier will provide products that meet industry standards and specifications, ensuring that you receive a durable and reliable material. Conversely, inferior quality materials can lead to premature wear, increased downtime, and higher maintenance costs.

Key Factors to Consider When Choosing a Supplier

1. Reputation and Experience Look for suppliers with a proven track record and extensive experience in the field of refractory materials. A well-established supplier is more likely to understand the unique needs of different industries and offer tailored solutions.

castable refractory material supplier

2. Product Range A good supplier should offer a comprehensive range of castable refractories, including different compositions and formulations that cater to various temperature ranges and industrial applications. This ensures that you can find the right material for your specific needs.

3. Technical Support Reliable suppliers often provide technical assistance, helping clients choose the right products and offering guidance on installation and maintenance. This support can be invaluable, particularly for businesses that may not have in-house expertise.

4. Quality Assurance Verify that the supplier adheres to quality control measures and industry certifications. This can be an indicator of their commitment to producing superior materials and ensuring customer satisfaction.

5. Customer Reviews and Testimonials Research and read reviews from other customers to gain insights into their experiences with the supplier. Satisfied customers often highlight the reliability and performance of the materials, as well as the quality of customer service.

6. Timely Delivery The efficiency of your operations depends on the timely delivery of materials. Choose a supplier known for their reliability in meeting deadlines, to minimize any disruptions to your production schedule.

Conclusion

In conclusion, the selection of a castable refractory material supplier is a critical step in ensuring the success of high-temperature applications. By considering factors such as reputation, product range, technical support, and quality assurance, businesses can make informed decisions that contribute to enhanced performance and durability in their operations. By investing time in selecting the right supplier, companies can significantly reduce the risk of operational issues and drive long-term success in their industries.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025