Nov . 23, 2024 00:11 Back to list

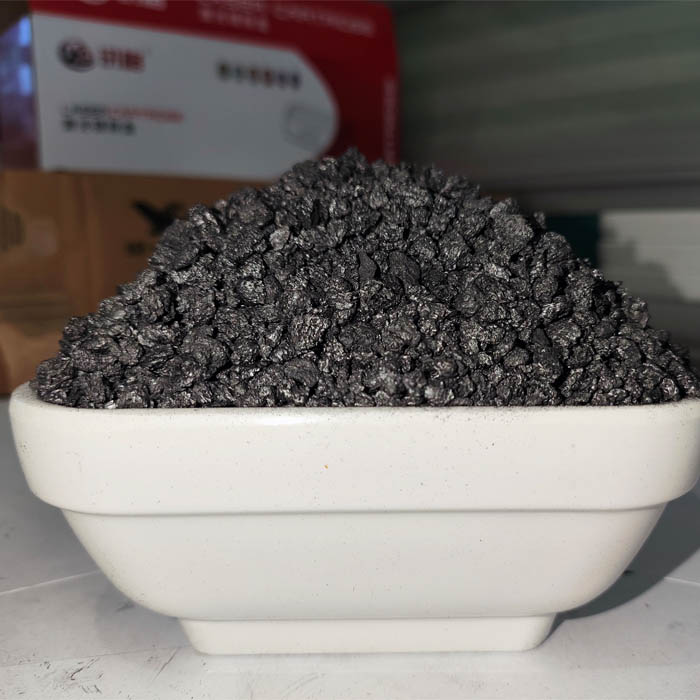

china fe-c alloy

The Significance of Fe-C Alloys in China’s Metallurgical Industry

In recent years, China has emerged as a powerhouse in the global metallurgical industry, notably in the production and application of iron-carbon (Fe-C) alloys. These alloys, primarily consisting of iron and carbon, are fundamental in various industrial applications, ranging from the construction sector to the manufacturing of tools and machinery. The Fe-C alloy's properties, including hardness, tensile strength, and ductility, make it an essential material in modern engineering.

Composition and Properties of Fe-C Alloys

Fe-C alloys typically encompass a carbon content ranging from 0.02% to 6.7%. This range creates different categories of steel and cast iron, each with unique properties. The mechanical characteristics of these alloys depend heavily on their carbon content and microstructure. For example, low carbon steels, typically containing below 0.3% carbon, exhibit high machinability and ductility, making them suitable for forming processes. In contrast, high carbon steels, containing more than 0.6% carbon, offer superior hardness and wear resistance, making them ideal for cutting tools.

The versatility of Fe-C alloys is evident in their application across various industries. In construction, structural steel made from low carbon alloys provides the necessary strength and flexibility for buildings and bridges. Additionally, medium carbon steels are widely used in manufacturing gears and shafts, while high carbon steels are employed in the production of springs and blades.

Production of Fe-C Alloys in China

China is the world's largest producer of Fe-C alloys, a title it has held for several years owing to its vast resources and advanced technological capabilities. The country employs various production methods, including the blast furnace method and electric arc furnaces, to manufacture these alloys. The adoption of cutting-edge technology has allowed the Chinese metallurgical industry to enhance efficiency and reduce environmental impact.

Moreover, China's investment in research and development has led to improvements in alloy compositions and processing techniques. This focus on innovation ensures that Chinese Fe-C alloys meet international standards, thus increasing their competitiveness in the global market. The government’s supportive policies, encouraging investment in the metallurgical sector, further bolster the growth of the Fe-C alloy industry.

china fe-c alloy

Environmental Considerations

The production of Fe-C alloys can have significant environmental impacts, particularly in terms of carbon emissions and energy consumption. As a response to these challenges, China is increasingly adopting more sustainable practices in its metallurgical processes. The implementation of cleaner production technologies, such as waste heat recovery systems and the use of alternative raw materials, has gained momentum. Additionally, the effort to recycle scrap metal has led to a circular economy approach within the industry, minimizing waste and reducing the carbon footprint associated with new alloy production.

Future Prospects for Fe-C Alloys

The future of Fe-C alloys in China appears promising, driven by the growing demand for high-quality materials in various sectors. With domestic infrastructure projects and manufacturing capabilities surging, the need for durable and efficient Fe-C alloys will continue to grow. Moreover, as industries evolve toward more advanced technologies, high-performance alloys, including advanced high-strength steels (AHSS) and specialty Fe-C alloys, are likely to gain traction.

Innovation will remain a critical factor in maintaining the edge of Chinese Fe-C alloys in the global market. Continued research into alloy properties and enhancements, alongside sustainable practices in production, will set the stage for future advancements in this field.

Conclusion

In summary, Fe-C alloys play a vital role in China’s metallurgical landscape, contributing significantly to various sectors while also presenting environmental challenges. With a strong focus on innovation, sustainability, and meeting global standards, the Fe-C alloy industry in China is poised for robust growth in the years to come, ensuring its position as a key player on the world stage. As such, the journey of Fe-C alloys represents not only a narrative of industrial progress but also a commitment to responsible manufacturing practices that align with global sustainability goals.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025