Jul . 20, 2024 11:51 Back to list

Choose Reliable Manufacturers for Bauxite and Galena Products with High Quality Standards

Understanding the Manufacturers of Bauxite and Galena

Bauxite and galena are two significant minerals that play crucial roles in various industries. Bauxite, primarily known as the principal source of aluminum, is an essential raw material for the global aluminum industry. On the other hand, galena, primarily composed of lead sulfide, is the most important ore for lead, an essential metal used in batteries, radiation shielding, and various alloys. The manufacturing processes and the market dynamics for these minerals are intricate and vital to several economic sectors, including construction, automotive, electronics, and green technologies.

Manufacturing of Bauxite

Bauxite is primarily extracted through open-pit mining. The ore is then processed through a refining technique known as the Bayer process, where bauxite is treated with sodium hydroxide at high temperatures to yield alumina (aluminum oxide). This alumina can subsequently be smelted to produce aluminum metal. The largest producers of bauxite include countries like Australia, China, Brazil, and Guinea. Australian manufacturers, in particular, dominate the market due to their vast reserves and efficient mining operations.

Manufacturers in the bauxite industry must navigate a variety of challenges, including environmental regulations, global market fluctuations, and technological advancements. Sustainable mining practices are becoming increasingly vital as consumers and governments prioritize environmental preservation. Innovations in mining technology aim to reduce waste and energy consumption, thus enhancing efficiency and minimizing ecological impact.

Manufacturing of Galena

Galena is extracted through both underground and open-pit mining methods. Once mined, the ore undergoes a series of processing steps, including crushing, grinding, and flotation, to separate the valuable lead from the waste materials. The result is lead concentrate, which can be further refined to produce pure lead through smelting processes.

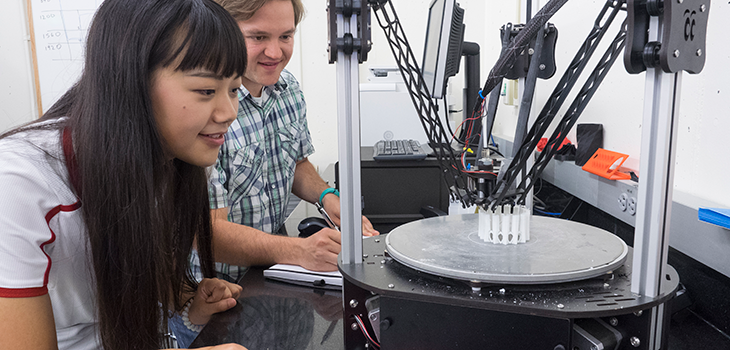

bauxite or galena manufacturer

Lead manufacturing also faces its share of challenges, particularly related to environmental concerns due to the toxicity of lead. As a result, manufacturers are implementing strict safety and environmental practices. The lead industry is also witnessing a trend towards recycling, where scrap lead from used batteries and other products is reclaimed and repurposed, significantly reducing the need for new mining.

The Market Dynamics

The market for both bauxite and galena is influenced by various factors, including global demand, trade policies, and technological advancements. For instance, the expanding electric vehicle (EV) market has increased the demand for aluminum, driving bauxite prices higher. In contrast, concerns over lead's health effects have prompted regulatory changes that impact the galena market. As countries like the United States and China impose stricter environmental regulations, manufacturers must adapt their mining and production processes to comply with new standards.

Furthermore, geopolitical factors play a significant role in the bauxite and galena markets. For instance, trade agreements or tariffs imposed on these minerals can shift production and affect prices globally. Manufacturers must remain vigilant and responsive to these market shifts, forging partnerships and diversifying their supply chains to mitigate risks.

Conclusion

In summary, the manufacturing of bauxite and galena is a complex interplay of mining, processing, and market dynamics. While these minerals are critical for modern industries, their extraction and production raise significant environmental and health concerns that necessitate responsible manufacturing practices. As global demand for aluminum and lead continues to evolve, so too must the strategies employed by manufacturers to ensure both economic viability and sustainability in the future. The future of bauxite and galena production will likely hinge on technological innovation, regulatory adaptation, and a commitment to sustainable practices that balance industrial needs with environmental stewardship.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025