Nov . 13, 2024 02:03 Back to list

chq wire rod manufacturer

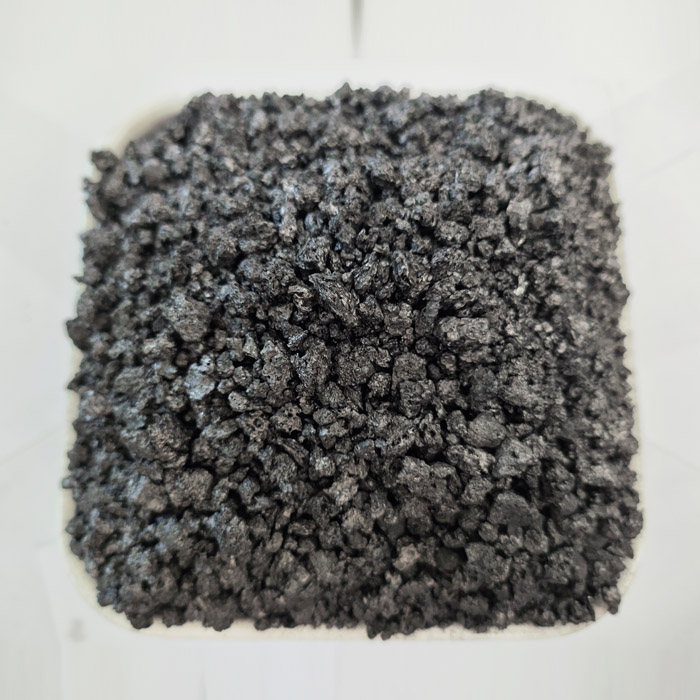

Understanding CHQ Wire Rod Manufacturing

CHQ (Cold Heading Quality) wire rods are essential components in various industrial applications, particularly in the production of fasteners and other cold-formed parts. The manufacturing of CHQ wire rods involves a sophisticated process designed to meet specific quality standards that ensure the end-products function effectively and reliably.

Raw Materials and Production Process

The production of CHQ wire rods begins with selecting high-quality raw materials, usually low carbon or medium carbon steels. The choice of steel impacts the final properties of the wire, including its tensile strength, ductility, and overall performance in various applications. Once the suitable raw material is selected, the manufacturing process involves several stages melting, casting, rolling, and finally, cooling.

In the melting phase, steel scrap and alloys are melted in a furnace, achieving a molten state suitable for casting. This molten steel is then poured into molds to form semi-finished products, typically billets. After cooling and solidifying, these billets are reheated and transformed into wire rods through a series of high-temperature rolling mills that reduce the diameter of the steel while enhancing its mechanical properties.

Quality Control Standards

chq wire rod manufacturer

The quality of CHQ wire rods is paramount, as they are often used in critical applications where failure is not an option. Manufacturers adhere to strict quality control measures throughout the production process. These include regular inspections and testing of the steel's chemical composition, microstructure, and mechanical properties. Advanced techniques such as ultrasonic testing and eddy current testing are employed to detect any internal defects that could compromise the performance of the wire rods.

Additionally, manufacturers often comply with international standards and certifications, such as ISO 9001, to ensure their products meet global quality benchmarks. This commitment to quality not only satisfies customer requirements but also builds the manufacturer's reputation in the market.

Applications of CHQ Wire Rods

The applications of CHQ wire rods are diverse. They are predominantly used in the automotive industry for producing components like bolts, nuts, and other fasteners. Beyond automotive, these wire rods are also utilized in industries such as aerospace, construction, and machinery manufacturing. Their versatility and durability make them a preferred choice for engineers and manufacturers alike.

Conclusion

In conclusion, CHQ wire rod manufacturing is a critical industrial process that combines high-quality raw materials, meticulous production techniques, and stringent quality control measures. As industries continue to evolve, the demand for reliable and high-performance wire rods will only increase. Manufacturers in this sector must remain vigilant and innovative to meet the changing needs of the market while maintaining the highest standards of quality in their products. As the backbone of many industrial applications, the significance of CHQ wire rods cannot be overstated.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025