Aug . 06, 2024 13:24 Back to list

Current Trends in Pricing for Calcined Petroleum Coke from Leading Manufacturers Worldwide

The Price of Calcined Petroleum Coke An Overview of the Market and Key Factors

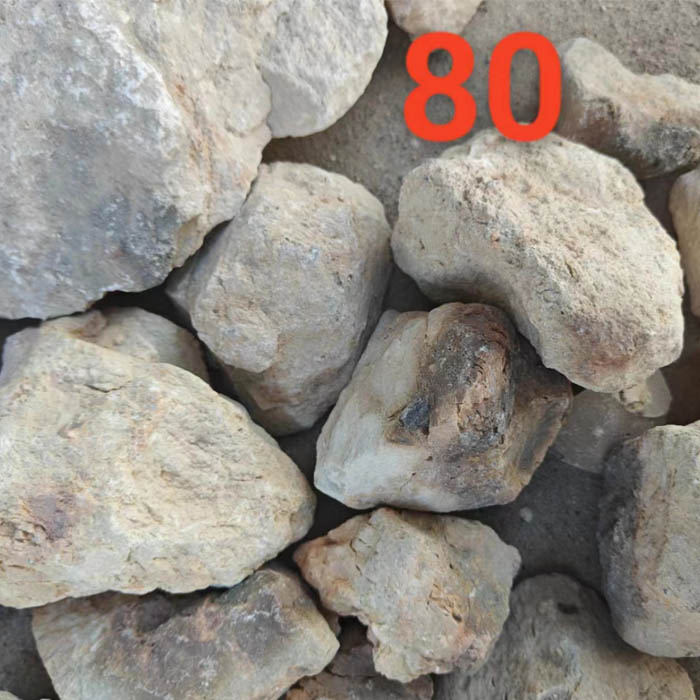

Calcined petroleum coke (CPC) is a critical material used in the aluminum industry, as well as in the production of electrodes for steel and titanium industries. It is produced from green petroleum coke, which is heated in a rotary kiln at high temperatures to remove volatile constituents. The resulting material is a high-carbon product with a low level of impurities, making it essential for various industrial applications. Understanding the pricing dynamics of CPC is crucial for manufacturers and end-users alike, as it can significantly influence production costs and profitability.

Current Market Trends

As of 2023, the price of calcined petroleum coke has experienced fluctuations influenced by several key factors. Global demand for aluminum products continues to rise, driven by increased use in automotive and construction sectors. This uptrend in aluminum production inevitably translates to higher demand for CPC, thus impacting its pricing. Additionally, the growing emphasis on lightweight materials to enhance energy efficiency in vehicles has led to an uptick in demand for aluminum, further solidifying the role of CPC in the supply chain.

Supply Chain Dynamics

The supply of CPC is closely tied to the availability of crude oil and the performance of the refining sector. A surge in crude oil prices can drive up the cost of petroleum coke, affecting the price of calcined products. Furthermore, geopolitical tensions, trade agreements, and regulatory changes can disrupt supply chains, resulting in additional cost pressures. In 2023, various regions have faced challenges, including logistical issues and increased energy costs, prompting price volatility in the CPC market.

Manufacturing Costs

price of calcined petroleum coke manufacturer

Manufacturers must consider not only the cost of raw materials but also the operational expenses associated with calcination processes. The energy-intensive nature of calcining petroleum coke requires substantial investments in infrastructure and technology. Consequently, any fluctuation in energy prices—particularly in electricity and natural gas—can have a direct impact on the overall cost of production. Furthermore, efficiency improvements, environmental regulations, and emissions standards may also influence the operating costs of CPC manufacturers, thereby affecting market prices.

Quality Considerations

Quality plays a significant role in determining CPC prices. High-quality CPC is sought after for its specific properties, such as high-density, low porosity, and minimal impurities. The production of high-grade calcined petroleum coke often incurs higher costs, thus influencing its market price. Additionally, the ability to meet customer specifications and industry standards can lead to premium pricing for CPC products, particularly in demanding applications such as aluminum smelting and electrode manufacturing.

Future Outlook

Looking ahead, the price of calcined petroleum coke will likely continue to be influenced by market demand, supply chain stability, and production costs. As the aluminum industry evolves, with innovations in recycling and new production methods, the dynamics of CPC pricing may also shift. Furthermore, global sustainability initiatives are prompting manufacturers to explore alternative feedstocks and production methods, which could reshape the CPC market landscape.

Conclusion

In summary, the price of calcined petroleum coke remains a complex interplay of market demand, supply chain issues, manufacturing costs, and quality considerations. As industries increasingly focus on sustainability and efficiency, the landscape of CPC pricing will undoubtedly evolve. For stakeholders in the CPC market, staying informed about these trends and factors is essential for competitive positioning and strategic planning in an ever-changing industrial environment.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025