Jul . 29, 2024 02:03 Back to list

Exploring Innovative Combinations of Metals in Modern Manufacturing Techniques and Applications for Enhanced Performance

The Role of Metal Combinations in Modern Metallurgy

Metallurgy, the science and technology of metals, has evolved significantly over the years, particularly with the development of advanced metal combinations. These combinations have become essential in various industries, from construction to aerospace, due to their enhanced properties and performance. The art of combining different metals to achieve superior characteristics is not just a practice; it's a critical component that drives innovation in material science.

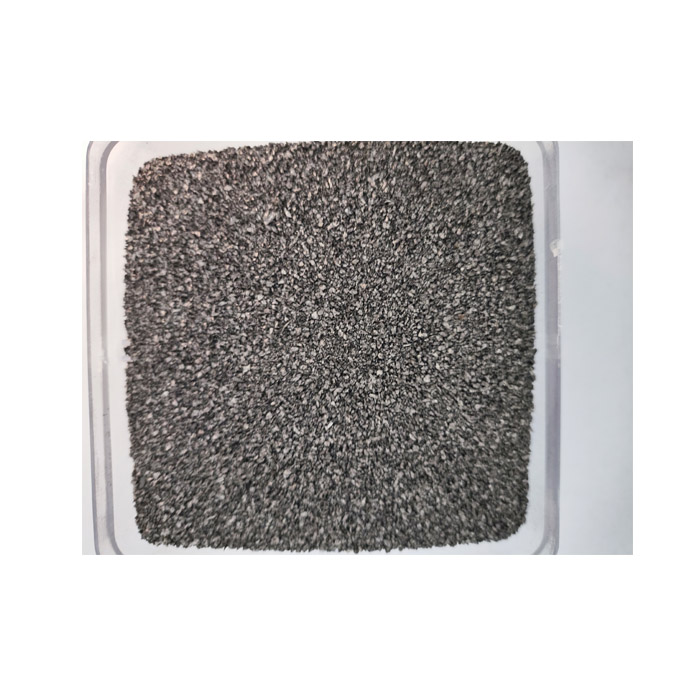

Metal combinations, or alloys, are created by melting base metals and adding other elements to enhance their mechanical, thermal, and chemical properties. The importance of these combinations cannot be overstated. For example, steel, an alloy of iron and carbon, is one of the most widely used materials in the world due to its high tensile strength and durability. Similarly, aluminum alloys are employed for their lightweight yet strong characteristics, making them ideal for applications in automotive and aerospace industries.

Manufacturers of metal combinations often face challenges in achieving the desired properties in their products. This necessitates extensive research and development efforts to explore various metallurgical processes. Techniques such as heat treatment, alloying, and the implementation of advanced manufacturing technologies like additive manufacturing or 3D printing play vital roles in optimizing the microstructure and performance of these alloys.

metallurgy 4 metal combinations manufacturers

One of the key considerations in metallurgy is the compatibility of different metals. Not all metals blend well; certain combinations can lead to undesirable effects like brittleness or corrosion. Therefore, manufacturers must meticulously select the metals for their desired applications. For instance, combining copper with tin results in bronze, an alloy renowned for its anti-corrosive properties and used extensively in marine applications.

Moreover, the environmental impact of metallurgy is an increasingly pressing concern. As industries strive for sustainability, manufacturers of metal combinations are exploring greener production methods. This includes recycling existing metals and minimizing the carbon footprint of their operations. By adopting innovative practices, companies are not only reducing waste but also contributing to a circular economy, which is vital for the future of our planet.

The demand for customized metal combinations has surged in recent years, driven by advancements in technology and changing market needs. Manufacturers are now able to tailor alloys specifically for applications in cutting-edge fields such as electronics, biomedical devices, and renewable energy technologies. For example, the development of high-strength, lightweight alloys is crucial for advancements in electric vehicles and energy-efficient structures.

In conclusion, metal combinations play a pivotal role in modern metallurgy, enabling manufacturers to produce materials that meet the complex demands of today’s industries. As technology continues to advance, the possibilities for innovative metal combinations will expand, leading to new applications that we may not yet imagine. The future of metallurgy is bright, with continuous research and development paving the way for more efficient, sustainable, and high-performance materials that will shape the world of tomorrow. As the industry evolves, the collaboration between metallurgists, engineers, and manufacturers will be essential in harnessing the full potential of metal combinations, ensuring they meet both the challenges of the present and the opportunities of the future.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025