Aug . 12, 2024 21:58 Back to list

Exploring the Benefits of Copper Pipe Insulation Materials for Enhanced Energy Efficiency and Durability

The Essential Role of Copper Pipe Insulation Materials in China's Industrial Landscape

In recent years, the industrial landscape in China has witnessed remarkable advancements, particularly in the realm of construction and manufacturing. Copper pipe insulation materials have emerged as critical components in this evolution, playing a pivotal role in enhancing energy efficiency, sustainability, and overall performance of various systems.

Copper pipes are prized for their excellent thermal conductivity and durability, making them ideal for a wide range of applications, from residential heating and cooling systems to industrial refrigeration and plumbing. However, without proper insulation, the efficiency of copper pipes can be compromised. Insulation materials serve to minimize heat loss and condensation, ensuring that energy is utilized optimally. This is where the importance of insulation materials becomes evident.

The Essential Role of Copper Pipe Insulation Materials in China's Industrial Landscape

Several types of insulation materials are commonly used with copper pipes, including foam, fiberglass, and rubber. Each material offers unique benefits, and the choice largely depends on the specific application and environmental conditions. For instance, closed-cell foam insulation is known for its superior thermal resistance and moisture barrier properties, making it ideal for outdoor installations and areas subject to high humidity. Conversely, fiberglass insulation is often favored for its cost-effectiveness and fire-resistant attributes, suitable for both residential and commercial applications.

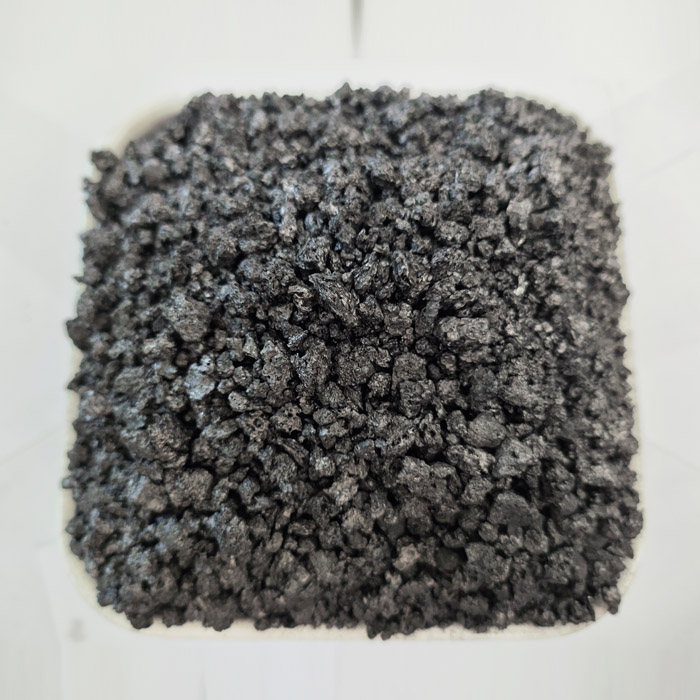

china copper pipe insulation material

In recent years, there has been a growing emphasis on sustainability and environmental impact within China's manufacturing sectors. Many companies are now opting for eco-friendly insulation materials that minimize their carbon footprints. Innovative insulation technologies are being developed to ensure that copper pipe insulation not only meets current energy standards but also anticipates future regulations aimed at reducing energy consumption and greenhouse gas emissions.

Moreover, China's commitment to green building practices has further propelled the demand for high-quality insulation solutions. The adoption of the Green Building Evaluation Standards encourages the use of materials that offer superior energy performance and environmental friendliness. As a result, manufacturers are increasingly investing in research and development to produce advanced copper pipe insulation materials that improve thermal efficiency while being less harmful to the environment.

Additionally, proper installation of insulation materials is paramount. Even the best insulation can fail to deliver its intended benefits if not installed correctly. Therefore, training and education for installers on best practices and innovation in insulation techniques are essential. The industry is keen on developing certification programs to ensure that standards are maintained and that installers are up to date with the latest advancements.

In conclusion, copper pipe insulation materials play an integral role in promoting energy efficiency and sustainability in China’s rapidly growing industrial sector. As urbanization continues to rise and environmental regulations become stricter, the demand for innovative and effective insulation solutions is expected to grow. By focusing on eco-friendly materials and ensuring top-notch installation practices, China can enhance the performance of its copper piping systems, paving the way for a more energy-efficient and sustainable future.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025