Jul . 26, 2024 15:00 Back to list

Exploring the Use of Recycled Materials from China for Sustainable Thermal Insulation Solutions

The Role of Recycled Materials in Thermal Insulation in China

As the global community continuously seeks sustainable solutions to address environmental challenges, China has emerged as a significant player in the recycling industry. Among various sectors, the use of recycled materials in thermal insulation has gained prominence as an effective method to enhance energy efficiency and reduce the carbon footprint in construction and manufacturing. This article explores the importance of recycled materials in thermal insulation applications within China, highlighting their benefits, challenges, and future prospects.

The Role of Recycled Materials in Thermal Insulation in China

One significant advantage of using recycled materials in insulation is their ability to reduce landfill waste. In a rapidly industrializing nation like China, where urbanization accelerates waste generation, repurposing materials is a vital strategy in waste management. By transforming discarded products such as plastics, textiles, and glass into insulation, China can significantly divert waste from landfills and reduce the need for virgin materials, which often require extensive energy-intensive processes to produce.

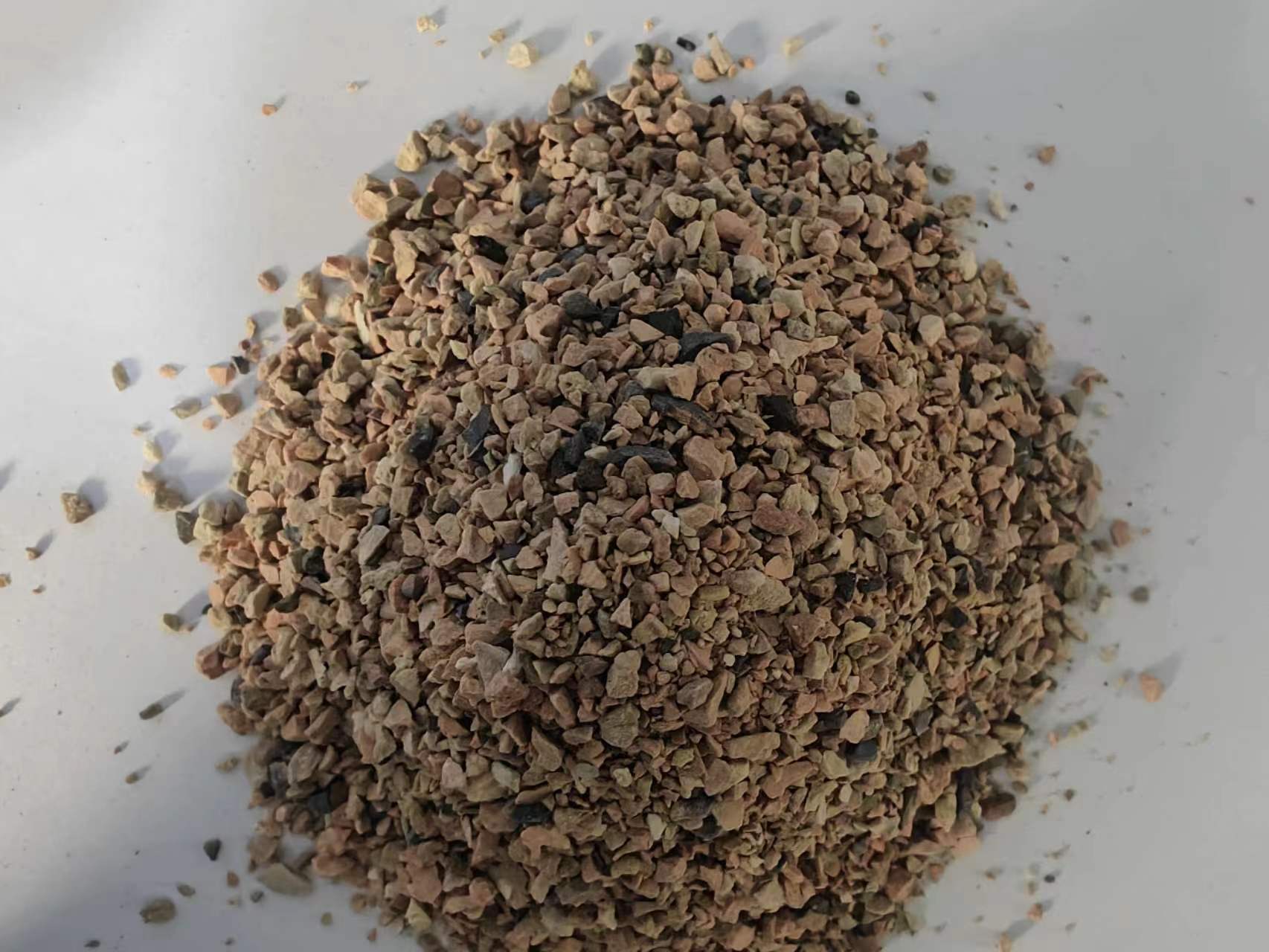

china recycled materials as thermal insulation

Furthermore, recycled insulation materials can offer competitive thermal performance. For instance, recycled polystyrene and polyurethane foams provide excellent thermal resistance, comparable to traditional insulation materials. In addition, using natural fibers—like straw, wool, or recycled denim—can create effective insulation solutions that are not only thermally efficient but also biodegradable, aligning with China's commitment to green building practices.

However, the journey toward widespread adoption of recycled materials in thermal insulation is not without its challenges. Quality control is a significant concern; recycled materials can vary significantly in performance due to inconsistencies in sourcing and processing. This inconsistency can discourage builders and manufacturers from choosing recycled options, favoring traditional materials that offer reliable performance. Moreover, the initial cost of recycled materials can be higher than that of conventional materials, primarily due to processing and quality assurance costs. To promote wider adoption, investments in technology and infrastructure for recycling processes are essential to improve quality, reduce costs, and establish trust among stakeholders.

Looking towards the future, China's government is promoting green technologies and sustainable practices as part of its broader environmental policy objectives. Initiatives such as the Circular Economy Promotion Law aim to enhance resource efficiency and encourage recycling industries' growth. By supporting research and development in recycled insulation materials, the government can drive innovation and establish regulatory frameworks that encourage builders and manufacturers to incorporate sustainable practices.

In conclusion, the integration of recycled materials into thermal insulation offers a promising avenue for enhancing energy efficiency and promoting sustainability in China’s construction and manufacturing sectors. While challenges remain, continued investment and support from the government, combined with advances in recycling technologies, can pave the way for a future where recycled materials play a central role in thermal insulation. As China continues to grapple with environmental issues, the development and adoption of recycled insulation materials could significantly contribute to a greener, more sustainable future.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025