Nov . 11, 2024 02:18 Back to list

Manufacturer of Exposed Concrete Aggregate Solutions for Superior Outdoor Designs

Understanding Exposed Aggregate Concrete A Guide for Manufacturers

Exposed aggregate concrete has gained immense popularity in recent years, blending aesthetics and durability in various applications. As a manufacturer in this niche, a thorough understanding of the concept, its benefits, and the manufacturing processes involved can set your products apart in a competitive market.

What is Exposed Aggregate Concrete?

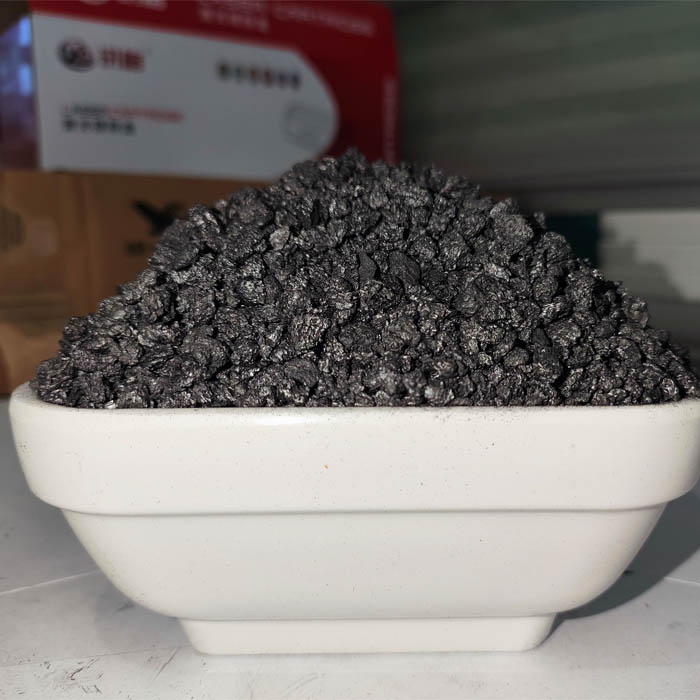

Exposed aggregate concrete is a technique used in concrete finishing that reveals the coarse aggregate within the concrete mix. This is achieved by removing the top layer of cement paste, which can be done by washing, brushing or using chemical retarders. The result is a surface that highlights the natural beauty of stones and minerals mixed into the concrete, offering a unique and attractive appearance.

This technique is not just for decorative purposes; it also improves the functionality of the concrete surface. The texture of exposed aggregate provides excellent traction, making it a popular option for driveways, walkways, patios, and even commercial spaces.

Benefits of Exposed Aggregate Concrete

1. Aesthetic Appeal One of the most significant advantages of exposed aggregate is its visual appeal. The variety of colors and textures available allows for creativity in design. Whether you prefer a vibrant look with colorful stones or a more natural appearance with earthy tones, the choices are nearly limitless.

2. Durability Concrete is known for its strength, and by exposing aggregate, you enhance this attribute. The process can strengthen the surface, making it more resilient to wear and tear over time, which is especially important in high-traffic areas.

3. Low Maintenance Exposed aggregate surfaces are relatively easy to maintain. Since the surface doesn't require painting or sealing like other decorative finishes, upkeep involves simple cleaning methods to remove dirt and debris. Additionally, its resistance to cracking and chipping minimizes the need for repairs.

4. Environmental Benefits Many exposed aggregate options utilize recycled materials or locally sourced aggregates, making them a more sustainable choice. This eco-friendly aspect aligns well with the growing demand for green building materials.

exposed concrete aggregate manufacturer

5. Versatility Exposed aggregate can be used in various applications, including residential and commercial properties. It can also be integrated into landscaping designs, pool decks, and outdoor spaces. This versatility makes it a vital product for manufacturers looking to diversify their offerings.

Manufacturing Process

The manufacturing process of exposed aggregate concrete involves several critical steps

1. Mix Design The success of exposed aggregate concrete begins with the correct mix design. This includes selecting the appropriate type and size of aggregates, as well as the right proportions of cement, water, and additives. Depending on the desired finish, the aggregates can vary in color, size, and shape.

2. Pouring the Concrete Once the mix is designed, the concrete is poured into forms. This is where precision is vital, ensuring even distribution and optimal compaction to eliminate air bubbles.

3. Setting and Finishing After the concrete is poured, it needs to set for a specified period. Once initially set, the surface is treated with a retarding agent that delays the hardening of the top layer of cement. This will allow for the later removal of the cement paste.

4. Exposing the Aggregate The final step involves exposing the aggregate by washing away the top layer of cement. This can be done using high-pressure water or scrubbing techniques. Care must be taken during this process to avoid damaging the exposed aggregate.

5. Curing Finally, the exposed aggregate surface needs to be cured properly to ensure maximum strength and durability. This can be achieved through covering the surface with curing blankets or applying curing compounds.

Conclusion

As a manufacturer of exposed aggregate concrete, understanding the intricacies of the product—from aesthetics and benefits to the manufacturing process—is crucial to meeting market demands. By focusing on quality and innovation while embracing eco-friendly practices, you can position your products favorably in an ever-evolving industry. With the right approach, your exposed aggregate concrete offerings can not only meet but exceed customer expectations, paving the way for greater market success.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025