Feb . 18, 2025 05:50 Back to list

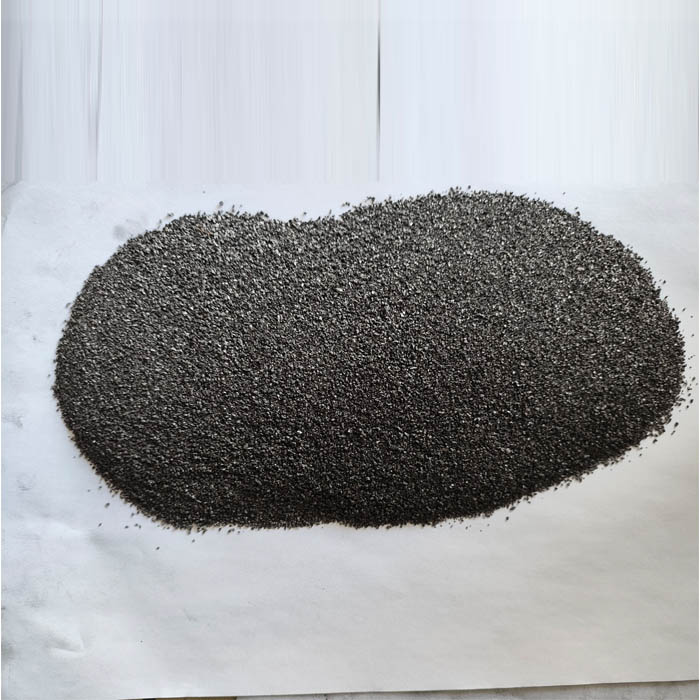

fe-c composite pellets

Revolutionizing the Metallurgical Industry with Fe-C Composite Pellets

The competitive edge of Fe-C composite pellets is further enhanced by ongoing research and development efforts focused on expanding their applicability and performance. Cutting-edge studies are exploring the integration of additional alloying elements to further refine the properties of Fe-C composite pellets, especially in extreme environments. Collaborative partnerships between research institutions and industrial leaders are catalyzing advancements that aim to optimize the composite for specific applications, offering tailored solutions that cater to unique industry needs. A paramount aspect of Fe-C composite pellets is their contribution to energy efficiency. By offering a material that can withstand high temperatures and pressures, these pellets enable processes that require less energy input, thereby reducing operational costs and contributing to energy conservation. This efficiency is further backed by their ability to facilitate faster and more consistent production processes, resulting in overall operational improvements and cost savings for manufacturers. Furthermore, the intrinsic properties of Fe-C composite pellets play a pivotal role in enhancing the quality and durability of end products. Their resilience to wear and tear, coupled with exceptional corrosion resistance, extends the lifespan of components, thereby ensuring long-term reliability and performance. This reliability significantly reduces maintenance and replacement costs, providing a substantial economic advantage to industries that incorporate these composites into their manufacturing processes. As industries continue to navigate the complexities of modern manufacturing challenges, Fe-C composite pellets present a reliable and innovative tool for achieving operational excellence. Their unique combination of strength, sustainability, and efficiency positions them as a crucial component in the future of metallurgical engineering. The forward trajectory of Fe-C composite pellets is marked by a commitment to continuous improvement and adaptation, ensuring they remain an essential asset in the pursuit of industrial innovation and sustainability. In conclusion, Fe-C composite pellets symbolize a transformative step forward in material science and engineering. Their impact reverberates across industries, offering not just enhanced performance but also paving the way for a more sustainable and efficient future. As the demand for superior materials continues to grow, Fe-C composite pellets stand ready to meet the challenge, delivering unmatched quality and reliability that resonate with the evolving needs and aspirations of the global manufacturing landscape.

The competitive edge of Fe-C composite pellets is further enhanced by ongoing research and development efforts focused on expanding their applicability and performance. Cutting-edge studies are exploring the integration of additional alloying elements to further refine the properties of Fe-C composite pellets, especially in extreme environments. Collaborative partnerships between research institutions and industrial leaders are catalyzing advancements that aim to optimize the composite for specific applications, offering tailored solutions that cater to unique industry needs. A paramount aspect of Fe-C composite pellets is their contribution to energy efficiency. By offering a material that can withstand high temperatures and pressures, these pellets enable processes that require less energy input, thereby reducing operational costs and contributing to energy conservation. This efficiency is further backed by their ability to facilitate faster and more consistent production processes, resulting in overall operational improvements and cost savings for manufacturers. Furthermore, the intrinsic properties of Fe-C composite pellets play a pivotal role in enhancing the quality and durability of end products. Their resilience to wear and tear, coupled with exceptional corrosion resistance, extends the lifespan of components, thereby ensuring long-term reliability and performance. This reliability significantly reduces maintenance and replacement costs, providing a substantial economic advantage to industries that incorporate these composites into their manufacturing processes. As industries continue to navigate the complexities of modern manufacturing challenges, Fe-C composite pellets present a reliable and innovative tool for achieving operational excellence. Their unique combination of strength, sustainability, and efficiency positions them as a crucial component in the future of metallurgical engineering. The forward trajectory of Fe-C composite pellets is marked by a commitment to continuous improvement and adaptation, ensuring they remain an essential asset in the pursuit of industrial innovation and sustainability. In conclusion, Fe-C composite pellets symbolize a transformative step forward in material science and engineering. Their impact reverberates across industries, offering not just enhanced performance but also paving the way for a more sustainable and efficient future. As the demand for superior materials continues to grow, Fe-C composite pellets stand ready to meet the challenge, delivering unmatched quality and reliability that resonate with the evolving needs and aspirations of the global manufacturing landscape.

Next:

Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025