Jul . 29, 2024 22:56 Back to list

Finding Reliable Suppliers for High-Quality Calcined Bauxite in the Global Market Today

The Importance of Calcined Bauxite Suppliers in the Global Market

Calcined bauxite, a critical raw material derived from bauxite ore, plays a pivotal role in various industrial applications, particularly in the production of aluminum and refractories. With the growing demand for high-quality calcined bauxite, the role of reliable suppliers has become increasingly significant in the global market. In this article, we will explore the importance of calcined bauxite suppliers, their impact on industries, and the factors to consider when selecting a suitable supplier.

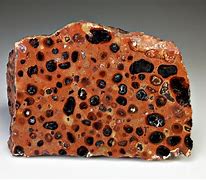

Understanding Calcined Bauxite

Calcined bauxite is produced by high-temperature heating of bauxite ore, which primarily consists of aluminum oxide (Al2O3). This process enhances its properties, making it suitable for various applications including the manufacturing of refractory materials, which can withstand extreme temperatures. Additionally, calcined bauxite is essential in the production of aluminum, cement, and iron and steel industries. Its unique attributes, such as high alumina content and low impurities, make it a preferred choice for these applications.

Role of Suppliers in the Industry

The supplier landscape for calcined bauxite is diverse, with key players located in different parts of the world. The reliability of these suppliers is crucial for industries that depend on consistent quality and supply for their operations. High-quality calcined bauxite ensures that end products meet stringent performance standards and regulatory requirements. A dependable supplier not only provides quality material but also supports industries through timely deliveries, competitive pricing, and technical assistance.

Moreover, suppliers are often responsible for maintaining ethical sourcing practices, transparency, and sustainability. As industries increasingly shift towards environmentally friendly practices, suppliers who prioritize sustainability in their operations are becoming more appealing. This trend is pushing many suppliers to adopt greener extraction and processing methods, minimizing environmental impact while ensuring that high-quality materials are still delivered.

Selection Criteria for Suppliers

When selecting a calcined bauxite supplier, several factors must be considered to ensure the best fit for specific industrial needs

calcined bauxite supplier

1. Quality Assurance Always evaluate the quality of the calcined bauxite offered. Request certifications and test results that showcase the material's properties, such as alumina content and impurity levels.

2. Reputation and Experience Research the supplier’s reputation in the market. Look for established suppliers with a proven track record and positive testimonials from other industry players.

3. Supply Chain Reliability Assess the supplier’s ability to meet demand consistently. A reliable supply chain is essential to prevent production delays.

4. Pricing Competitive pricing is important, but it should not be the only consideration. Analyze the overall value proposition, taking into account quality, service, and reliability.

5. Customer Support Good customer service and technical support can greatly enhance your experience with a supplier. Choose a supplier that is responsive and eager to assist with inquiries or issues.

6. Sustainability Practices Consider suppliers that implement sustainable practices in their operations. Many industries are moving towards greener alternatives, and partnering with environmentally conscious suppliers can enhance your brand’s reputation.

Conclusion

Calcined bauxite suppliers are integral to the industries that rely on this versatile material. As demand continues to rise, the importance of choosing a trustworthy supplier cannot be underestimated. By considering quality, reputation, reliability, pricing, customer support, and sustainability practices, industries can secure a partnership that drives productivity and innovation. As global markets evolve, those who adapt to changing dynamics and prioritize these factors will likely thrive in the competitive landscape of calcined bauxite supply.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025