Sep . 08, 2024 09:47 Back to list

Premium Gray Graphite Supplier | High-Quality Graphite Products

Gray Graphite Supplier Meeting the Demands of Diverse Industries

Graphite is a versatile material that finds its applications in numerous industries, from automotive to electronics. Among the various types of graphite, gray graphite stands out due to its unique properties, making it indispensable in many industrial processes. This article explores the role of gray graphite suppliers and the significance of their products in today’s market.

Gray graphite, recognized for its excellent thermal conductivity, lubricating properties, and resistance to high temperatures, is used extensively in manufacturing brake linings, gaskets, and seals. The increasing demand for these products necessitates a reliable supply chain, and thus, the role of gray graphite suppliers is critical.

One of the key factors when choosing a gray graphite supplier is the quality of the material. High-quality gray graphite is characterized by its purity, consistency, and performance under various conditions. Suppliers that prioritize quality often conduct rigorous testing and quality assurance protocols to ensure that their graphite meets industry standards. As industries continue to push for efficiency and longevity in their products, the demand for top-tier gray graphite experiences unprecedented growth.

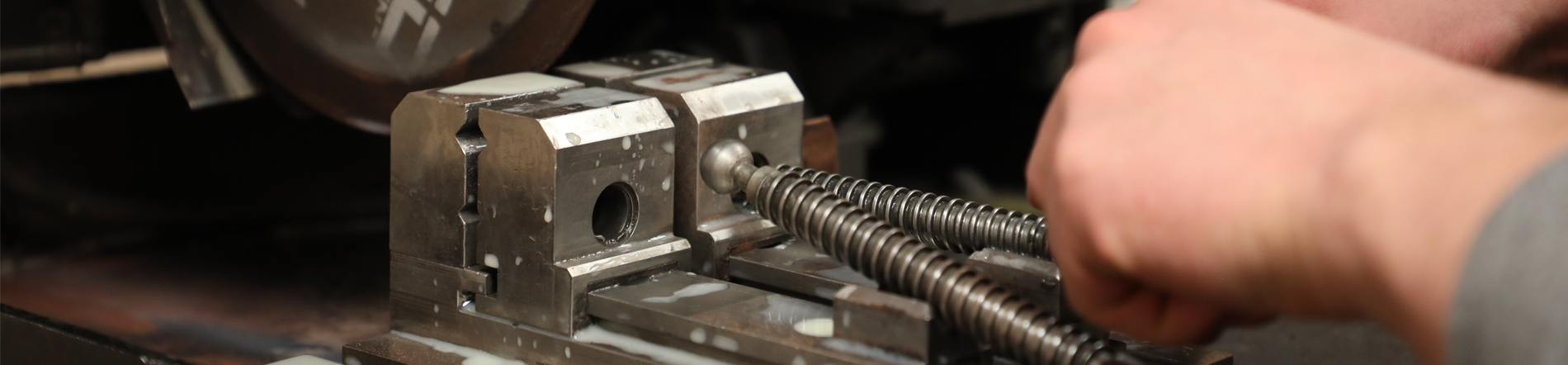

gray graphite supplier

Additionally, gray graphite suppliers must stay ahead of market trends. The automotive industry, for instance, is gravitating towards electric vehicles (EVs), which require advanced materials. This transition opens new opportunities for gray graphite suppliers, as the material is critical in components such as motor brushes and battery electrodes. Suppliers that can innovate and provide high-performance gray graphite tailored for these applications will have a significant competitive advantage.

Moreover, environmental considerations are becoming increasingly important for suppliers. The production of graphite, particularly through traditional mining methods, can have substantial impacts on the environment. As a result, many manufacturers are turning to suppliers that prioritize sustainable practices—such as recycling graphite and minimizing waste during the production process. Suppliers who adopt green initiatives not only contribute positively to the planet but also align themselves with the growing consumer demand for environmentally friendly products.

Geographical factors also play a vital role in the effectiveness of gray graphite suppliers. Suppliers located near major industrial hubs can provide quicker and more cost-effective deliveries, enhancing their appeal in the marketplace. Additionally, a global network can further improve availability and ensure that clients across different regions have access to gray graphite as needed.

In conclusion, gray graphite suppliers are crucial players in the supply chain of several key industries. Their ability to provide high-quality, innovative, and sustainable products will significantly influence the development and efficiency of technologies we rely on today. By maintaining rigorous quality standards and adapting to industry trends, these suppliers not only meet current demands but also pave the way for a more sustainable and technologically advanced future. As industries evolve, the partnership between manufacturers and gray graphite suppliers will undoubtedly continue to be vital to achieving excellence in production and performance.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025