Sep . 08, 2024 02:39 Back to list

High Carbon Steel Wire Rod Manufacturer - Premium Quality Wire Rods

High Carbon Steel Wire Rod Manufacturer A Cornerstone of Modern Industry

High carbon steel wire rod is a critical material in various industrial applications, known for its superior strength and excellent tensile properties. Manufacturers of high carbon steel wire rod play a pivotal role in supplying the essential raw material required for various sectors, including automotive, construction, and manufacturing.

High carbon steel typically contains carbon content ranging from 0.6% to 1.0%, enhancing its hardness and strength. This makes it particularly suitable for applications that demand high wear resistance and durability. The production process involves the careful selection of raw materials, stringent controls during melting and casting, and precise rolling processes. Consequently, manufacturers who specialize in high carbon steel wire rod must maintain high operational standards to ensure the quality and reliability of their products.

One of the primary applications of high carbon steel wire rod is in the manufacturing of wire, cables, and springs. These components require not just strength but also the ability to withstand deformation without losing structural integrity. For example, in the automotive industry, high carbon steel wire is utilized in producing suspension springs, which absorb shocks and enhance the ride quality of vehicles. Likewise, in construction, wire ropes and cables made from high carbon steel are commonly used for lifting and rigging, where safety and performance are paramount.

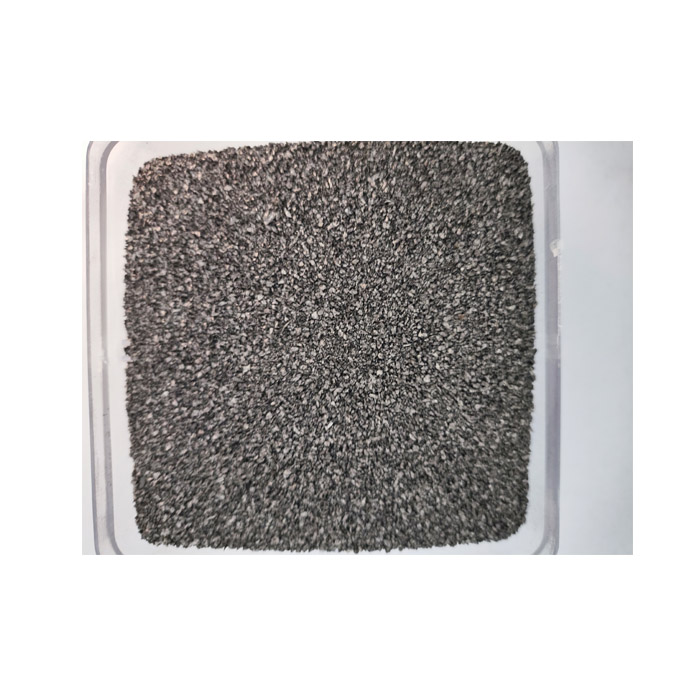

high carbon steel wire rod manufacturer

The production of high carbon steel wire rod follows a series of steps that begin with the melting of iron ore and scrap steel in an electric arc furnace. This process allows for precise control over the carbon content and other elemental additions. Following this, the molten steel is cast into billets, which are then rolled into wire rods. Manufacturers employ advanced rolling techniques that can include hot rolling, cold drawing, and heat treatment to achieve the desired mechanical properties.

Quality control is paramount in the manufacturing of high carbon steel wire rod. Leading manufacturers implement rigorous testing protocols throughout the production process. This includes checks for tensile strength, yield strength, elongation, and surface quality. Advanced technologies, such as non-destructive testing, are employed to detect any internal or external defects, ensuring that the final product meets both industry standards and customer specifications.

The global demand for high carbon steel wire rod is driven by the continuous growth of industries such as automotive manufacturing, construction, and general engineering. As these sectors expand, the need for high-performance materials becomes even more critical. Manufacturers are not only focusing on production efficiency but also on sustainable practices, such as recycling scrap materials to minimize waste and reduce the environmental impact.

In conclusion, high carbon steel wire rod manufacturers are integral to multiple industries that rely on strong, durable materials. Their role enhances the supply chain of critical components and ensures that high standards are maintained across various applications. As industries evolve, these manufacturers will continue to play a vital role in shaping the materials that underpin modern infrastructure and technology. Investing in high-quality, high carbon steel wire rod can lead to improved performance and longevity of the end products, making it a preferred choice for engineers and manufacturers alike.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025