Dec . 10, 2024 11:40 Back to list

Innovative Techniques for Producing Superior Quality EAF Steel in Modern Manufacturing Processes

High-Quality EAF Steel Making A Modern Approach to Steel Production

Electric Arc Furnace (EAF) steel making has emerged as a cornerstone of the modern steel industry, renowned for its efficiency, flexibility, and environmental benefits. Unlike traditional methods that typically rely on blast furnaces, EAF production utilizes recycled scrap metal as its primary raw material, significantly reducing energy consumption and emissions. This article delves into the intricacies of high-quality EAF steel making, highlighting its processes, benefits, and the future prospects it holds.

The EAF Process A Brief Overview

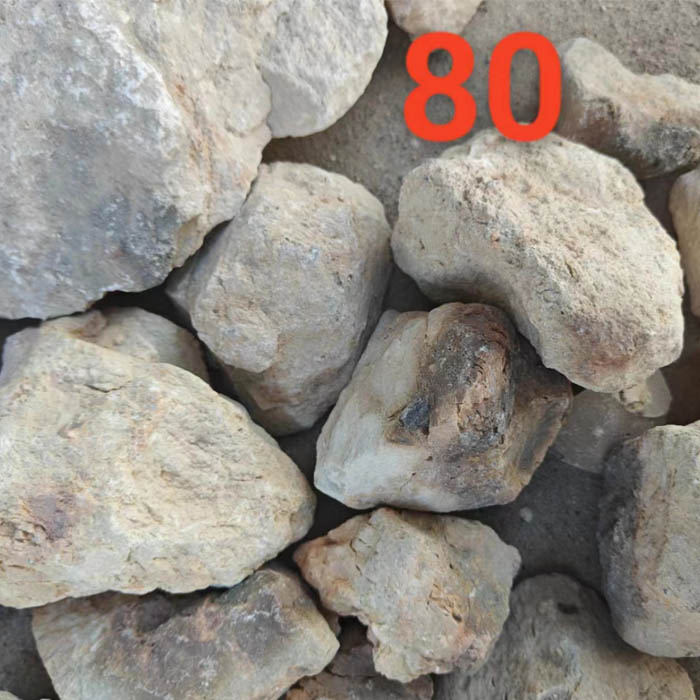

The EAF process begins with the collection and preparation of scrap steel, which is often sourced from end-of-life products like automobiles, appliances, and construction materials. This scrap is then charged into the furnace. One of the key features of EAF steel making is its reliance on an electric arc to melt the scrap. Electrodes, typically made of graphite, produce an electric arc that generates extreme heat, allowing the steel to reach melting temperatures of approximately 1,600 degrees Celsius (2,912 degrees Fahrenheit).

Once melted, the molten steel is refined through various metallurgical processes. This phase involves the addition of alloys and other materials to achieve specific chemical compositions and properties tailored to end-user specifications. Common alloying elements include manganese, nickel, chromium, and vanadium, each enhancing certain mechanical properties of the steel.

Enhancing Steel Quality

The quality of steel produced in EAFs is often measured by its cleanliness, mechanical properties, and consistency. High-quality EAF steel is typically characterized by low impurity levels, which can significantly affect its performance in applications ranging from construction to automotive manufacturing. To achieve this high level of quality, several advanced techniques are employed

1. Process Control Automated systems monitor various parameters like temperature, chemistry, and processing time, ensuring consistency and quality in every batch.

2. Ultra-Low Emission Technologies New technologies aimed at reducing emissions during the melting process have become crucial. Innovations like off-gas cleaning systems capture pollutants before they escape into the atmosphere, contributing to improved environmental outcomes.

3. Secondary Metallurgy After initial melting, the molten steel often undergoes secondary metallurgy processes, such as ladle refining and vacuum degassing. These treatments help purify the steel and further tailor its composition, ensuring that it meets stringent industry standards.

high quality eaf steel making

Benefits of EAF Steel Making

The adoption of EAF steel making offers numerous advantages over traditional methods

- Environmental Sustainability EAF production is significantly more sustainable, utilizing approximately 60% less energy than blast furnaces. Additionally, it has a lower carbon footprint, making it more attractive in today's eco-conscious market.

- Flexibility EAFs are capable of producing varied steel grades without extensive retooling. This adaptability allows manufacturers to respond quickly to market demands and customize products according to specific customer needs.

- Recycling EAF largely relies on scrap steel, diverting tons of metal from landfills and promoting a circular economy. This not only conserves virgin raw materials but also supports the recycling industry.

Future Outlook

The future of high-quality EAF steel making looks promising, driven by technological advancements and increasing market demand for sustainable products. The steel industry is continuously innovating, with research focused on improving the efficiency of electric arc processes and further reducing environmental impacts.

Moreover, the global emphasis on green technologies and decarbonization efforts will likely propel the EAF method to the forefront of steel production strategies. As industries across the globe seek to decrease their carbon footprints, the adaptability and sustainability of EAF steel making will be invaluable.

In conclusion, high-quality EAF steel making represents a pivotal shift in the metal industry, emphasizing efficiency, quality, and sustainability. As technology advances and environmental concerns rise, the importance of this innovative steel production method will only increase, shaping a greener future for generations to come.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025