Dec . 04, 2024 17:00 Back to list

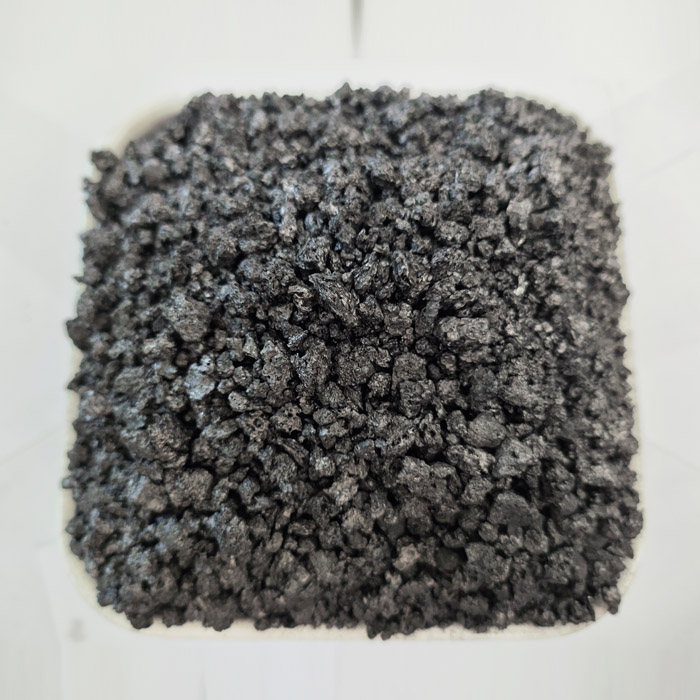

high quality hose for refractory materials

High-Quality Hose for Refractory Materials Essential for Efficient Operations

In the world of industrial manufacturing, the movement of materials is a critical process that can significantly influence productivity and operational efficiency. One area that often receives less attention than it deserves is the transporting of refractory materials. Refractory materials, known for their ability to withstand extreme temperatures, are used in various industries, including steel, cement, and petrochemical facilities. The transportation of these materials requires specialized equipment, notably high-quality hoses designed specifically to handle the unique demands of refractory materials.

Understanding Refractory Materials

Refractory materials are notable for their durability and heat resistance, which makes them indispensable in high-temperature applications. These materials include bricks, castables, and ceramics used in furnaces, kilns, and reactors. However, moving these dense and often abrasive materials presents unique challenges. Conventional hoses may not withstand the thermal stress or the abrasive nature of these materials, leading to potential downtime and increased maintenance costs.

The Role of High-Quality Hoses

The importance of high-quality hoses in the transportation of refractory materials cannot be overstated. Several factors make these hoses vital for operational efficiency

1. Durability Hoses used in refractory applications must be robust enough to resist abrasion and wear caused by the movement of dense materials. High-quality hoses are made from advanced materials that provide excellent resistance to wear and tear.

2. Temperature Resistance Refractory materials can reach extremely high temperatures, making it essential for hoses to withstand such heat without degrading. High-quality hoses are designed to endure these temperatures, ensuring that the material being transported remains stable and effective.

3. Flexibility and Ease of Handling Despite their strength, high-quality hoses should also offer flexibility to navigate through manufacturing spaces easily. This flexibility ensures that hoses can be routed as needed without kinking or damage, facilitating a smooth workflow.

4. Safety The movement of refractories can pose risks in the workplace. High-quality hoses minimize the chances of leaks and ruptures, which can lead to hazardous conditions. Ensuring safety through reliable hose materials is essential for protecting workers and equipment alike.

high quality hose for refractory materials

5. Cost Efficiency While the initial investment in high-quality hoses may be higher than basic options, they often lead to long-term savings. Reduced downtime, lower maintenance costs, and increased operational reliability contribute to a more cost-effective solution overall.

Selecting the Right Hose

Choosing the right hose for transporting refractory materials involves several considerations

- Material Composition Look for hoses made from materials that are specifically designed to provide heat resistance and durability, such as high-grade rubber or thermoplastic elastomers.

- Hose Diameter The diameter of the hose must match the requirements of the application, ensuring optimal flow rates without causing blockages.

- Reinforcement Layers Hoses with multiple layers of reinforcement offer increased strength and durability. This is particularly important in high-pressure applications where failure of the hose could lead to a catastrophic incident.

- Compatibility with Equipment Ensure that the hoses are compatible with existing machinery, including fittings and connectors, for seamless integration into current operational practices.

Conclusion

In conclusion, high-quality hoses designed for refractory materials are indispensable for industries that rely on these advanced materials. Their role in ensuring safe, efficient, and cost-effective transportation cannot be overlooked. By investing in the right hoses, companies can enhance their operational efficiency, reduce downtime, and ultimately boost their productivity. As industries continue to evolve, the need for specialized equipment such as high-quality hoses will remain at the forefront of maximizing performance and safety in refractory material handling. Industries must prioritize the selection of durable, heat-resistant hoses to navigate the complexities of dealing with these critical materials effectively.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025