Oct . 31, 2024 19:58 Back to list

Exploring the Four Most Resilient Metals in High-Quality Metallurgy

The Four Strongest Metals in High-Quality Metallurgy

Metallurgy, the science of metals, plays a pivotal role in various industries, from construction to aerospace. Among the plethora of metals available, certain alloys stand out for their exceptional strength and durability. Here, we explore the four strongest metals in high-quality metallurgy, each renowned for its unique properties and applications.

The Four Strongest Metals in High-Quality Metallurgy

2. Titanium Next is titanium, often celebrated for its incredible strength-to-weight ratio. With a tensile strength of approximately 1000 MPa, titanium is significantly lighter than steel but offers comparable strength. This unique property makes it a favorite in the aerospace industry, where reducing weight can lead to significant fuel savings and improved performance. Moreover, titanium is highly resistant to corrosion, making it suitable for medical implants and marine applications.

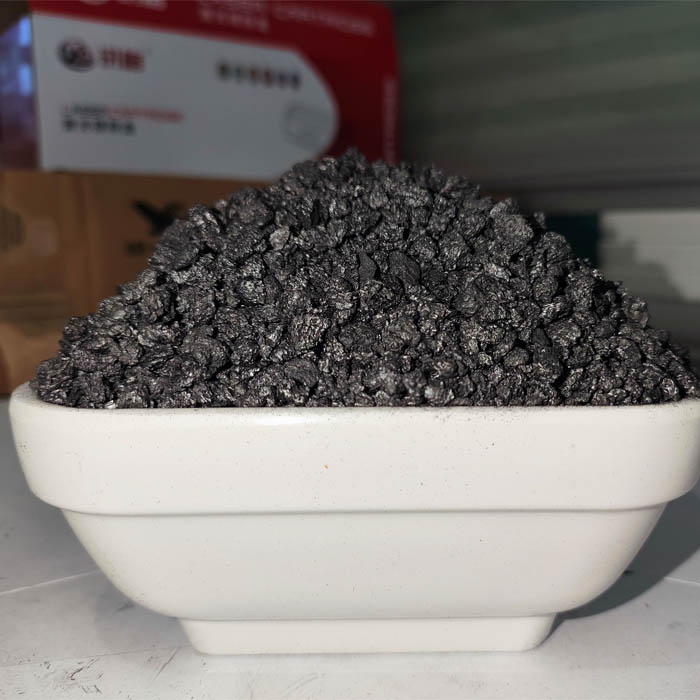

high quality metallurgy 4 strongest metal

3. Chromium Chromium, a crucial component in stainless steel, boasts a tensile strength of around 900 MPa. Its primary role in metallurgy is to enhance the hardness, toughness, and corrosion resistance of steel. Chromium’s ability to create a passivation layer on its surface helps to protect it from oxidizing agents, thus extending the life of the metal. It is widely used in automotive and plumbing industries, underscoring its importance in everyday applications.

4. Steel Alloys Finally, steel alloys deserve a mention for their exceptional strength, particularly high-carbon steels and tool steels. These alloys can achieve tensile strengths exceeding 2000 MPa, making them ideal for construction, manufacturing, and tooling applications. The addition of elements like chromium, nickel, and molybdenum enhances their strength and durability, making them indispensable in engineered structures and heavy machinery.

In conclusion, the world of high-quality metallurgy offers a range of metals that excel in strength and durability. Tungsten, titanium, chromium, and steel alloys are at the forefront, each serving specialized functions across various industries. Understanding their properties not only aids in selecting the right material for specific purposes but also propels innovation in technology and engineering.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025