Oct . 06, 2024 02:13 Back to list

high quality msds petroleum coke

High Quality MSDS for Petroleum Coke

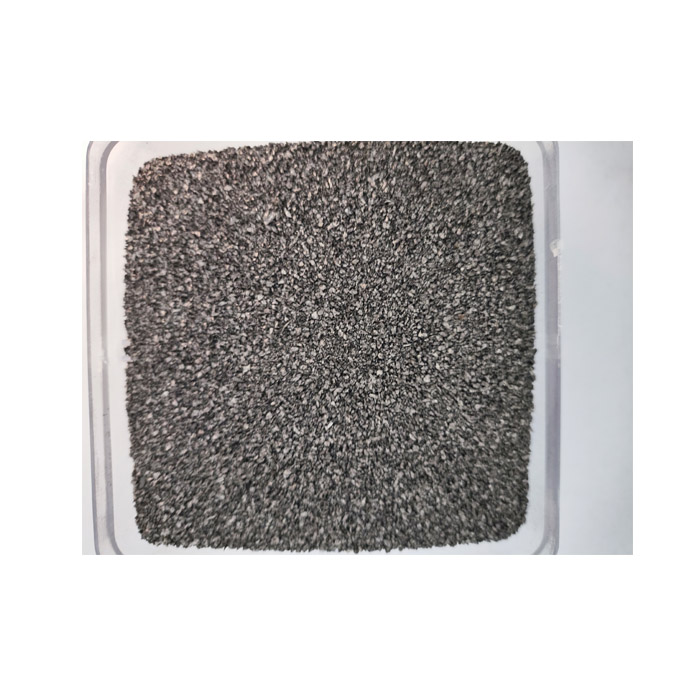

Petroleum coke, often referred to as pet coke, is a key byproduct of the oil refining process. It is produced from the carbonization of crude oil, which results in a solid carbon material that has various applications across multiple industries. The use of petroleum coke has grown significantly due to its properties as an economical carbon source, making it integral to the production of aluminum, steel, and even in cement manufacturing. As with any industrial material, understanding its safety and handling requirements is paramount, and that's where the Material Safety Data Sheet (MSDS) comes into play.

The MSDS for petroleum coke is a critical document that provides information on the chemical properties, hazards, handling, and safe usage of this material. It serves as a crucial reference for workers and safety personnel to understand the risks involved and the necessary precautions to mitigate them. A high-quality MSDS will cover various essential components, ensuring comprehensive safety guidance.

Firstly, a well-compiled MSDS will begin with a product identification section, providing details such as the chemical name, synonyms, and the intended use of petroleum coke

. This ensures that anyone referencing the MSDS can quickly ascertain the material being discussed.Secondly, the physical and chemical properties of petroleum coke are outlined. This includes its appearance, odor, melting point, boiling point, density, and solubility. Understanding these characteristics is vital, as they play a significant role in assessing the material's behavior under different conditions, which is crucial for safe storage and transportation.

high quality msds petroleum coke

The hazard identification section is arguably one of the most critical parts of any MSDS. It highlights the potential risks associated with petroleum coke, including inhalation of dust, skin and eye irritation, and potential fire hazards. Clear descriptions of these risks, along with recommended safety measures, empower workers to handle the material safely.

Furthermore, the MSDS should detail appropriate first-aid measures in case of exposure. It is essential for workers to know the necessary actions to take in case of inhalation, skin contact, or eye exposure to mitigate any adverse effects quickly.

Protective measures play a key role in ensuring safety when working with petroleum coke. A high-quality MSDS will clearly specify the personal protective equipment (PPE) required, including gloves, safety goggles, and respiratory protection, along with recommendations for hygiene practices to follow.

Finally, the disposal and environmental considerations section should not be overlooked. Proper disposal methods must be outlined to ensure compliance with local regulations, thereby minimizing the environmental impact of petroleum coke waste.

In conclusion, a high-quality MSDS for petroleum coke is an indispensable tool for ensuring safety in its handling and use. By providing detailed information on hazards, safety precautions, and proper handling procedures, it helps to safeguard not only the workers involved but also the environment. This underscores the need for industries utilizing petroleum coke to prioritize comprehensive safety documentation and training to enhance workplace safety and compliance.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025