Sep . 25, 2024 09:19 Back to list

Exploring High-Quality SWRCH50K for Enhanced Performance and Efficiency in Applications

The High-Quality SWRCH 50K A Revolution in Material Science

In recent years, the demand for high-performance materials has skyrocketed across various industries, from aerospace to automotive and electronics. Among the leading innovations in this domain is the High-Quality SWRCH 50K, a material that has garnered attention for its exceptional properties and versatility. This article delves into the characteristics, applications, and benefits of SWRCH 50K, shedding light on its significance in modern engineering.

The High-Quality SWRCH 50K A Revolution in Material Science

One of the standout features of SWRCH 50K is its excellent machinability. Unlike traditional high-carbon steels, which can be difficult to work with, SWRCH 50K has been optimized to allow for easier cutting and shaping, making it ideal for precision engineering. This element is particularly critical in industries where tolerances are tight, and failure of components can lead to catastrophic results. The ease of machining not only reduces production time but also decreases wear on tools, further enhancing manufacturing efficiency.

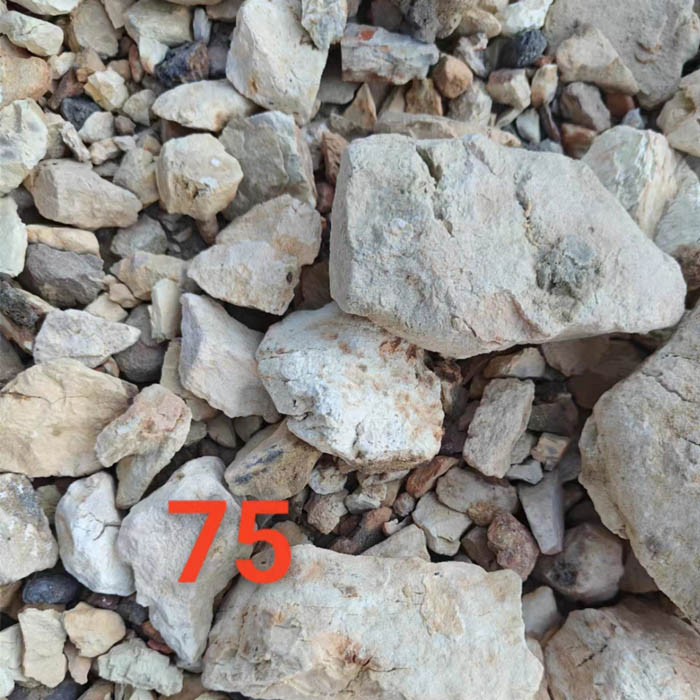

high quality swrch50k

The applications of SWRCH 50K are widespread and varied. In the automotive industry, it is frequently used in components that require high tensile strength and fatigue resistance, such as gears, shafts, and fasteners. The aerospace sector also benefits from SWRCH 50K, as its lightweight yet robust nature allows for the development of parts that can withstand the extreme conditions of flight without compromising safety or performance.

Another compelling advantage of SWRCH 50K is its excellent resistance to wear and tear. This makes it particularly suitable for high-load applications where friction and abrasion are concerns. Coupled with its ability to maintain its properties even in harsh environments, SWRCH 50K emerges as a preferred choice for manufacturing equipment and machinery that demand longevity and reliability.

Moreover, in the realm of sustainability, SWRCH 50K is an attractive option. The prolonged lifespan of components made from this material means less frequent replacements and reduced waste. When combined with recycling processes, the environmental footprint of manufacturing using SWRCH 50K can be significantly minimized, aligning with the global movement towards more sustainable industrial practices.

In conclusion, the High-Quality SWRCH 50K represents a significant advancement in material science, offering a blend of strength, durability, and machinability that meets the demanding requirements of modern industries. As technological advancements continue to develop and the push for sustainable solutions intensifies, materials like SWRCH 50K will play an essential role in shaping the future of engineering and manufacturing, ensuring that we can meet both performance expectations and environmental responsibilities effectively.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025