Nov . 25, 2024 12:34 Back to list

high temperature thermal insulation materials factories

High Temperature Thermal Insulation Materials Factories and Their Importance

In today’s industrial landscape, high temperature thermal insulation materials play a crucial role in enhancing energy efficiency and ensuring safety in various applications. These materials are specifically designed to withstand extreme heat conditions, making them essential in industries like metallurgy, ceramics, petrochemicals, and aerospace. As businesses strive to minimize energy costs and meet stringent environmental regulations, the demand for high-performance thermal insulation is on the rise.

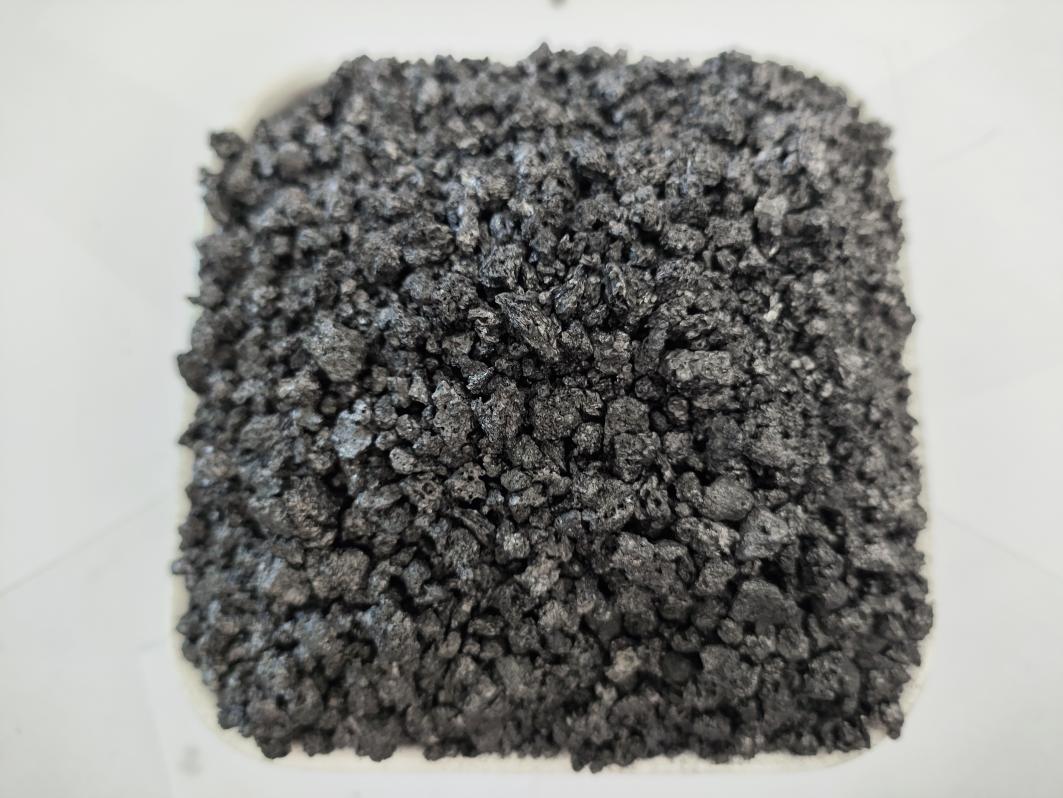

High temperature insulation materials are typically categorized based on their composition and application. Common types include ceramic fibers, mineral wool, and refractory materials. Ceramic fibers, for instance, can withstand temperatures exceeding 1,000 degrees Celsius and are often used in furnaces, kilns, and other high-temperature environments. Mineral wool, made from natural or synthetic fibers, is not only effective at high temperatures but also offers excellent sound absorption properties. Refractory materials, on the other hand, are essential for lining furnace interiors and must possess both thermal and mechanical stability.

The production of these high temperature thermal insulation materials involves sophisticated manufacturing processes tailored to meet specific technical requirements. Factories specializing in this field are equipped with advanced technologies that ensure the consistent quality and reliability of the insulation products. These factories utilize automated production lines that streamline the manufacturing process, reduce waste, and enhance precision. Furthermore, stringent quality control measures are implemented throughout the production cycle to ensure that the final products meet international standards and customer specifications.

high temperature thermal insulation materials factories

The significance of high temperature thermal insulation materials extends beyond just energy savings; they also contribute to fire safety and regulatory compliance in various industries. By minimizing heat loss, these materials help reduce greenhouse gas emissions, thus playing an essential role in combating climate change. Additionally, they help protect equipment and personnel from extreme heat, thereby reducing the risk of accidents and injuries in the workplace.

In recent years, the high temperature insulation materials market has witnessed substantial growth due to several factors. The increasing demand for energy-efficient solutions, coupled with the rising costs of energy, has driven industries to seek advanced insulation options. Additionally, the ongoing development of new materials and technologies is enhancing the performance of high temperature insulation, making them more appealing to manufacturers and end-users alike.

The geographic distribution of factories producing high temperature thermal insulation materials is noteworthy as well. While many key players are located in industrial regions, they are also expanding their operations globally to meet the growing demand. Countries such as China, the United States, and Germany are leading the production of these materials, driven by their large manufacturing bases and technological advancements.

In conclusion, high temperature thermal insulation materials are vital to modern industry, enhancing energy efficiency while ensuring safety in high heat applications. The factories that produce these materials play a crucial role in meeting the evolving needs of various sectors. As technology continues to advance and environmental regulations become stricter, the importance of high quality thermal insulation will only grow, making it a priority for manufacturers across the globe. Investing in high temperature insulation technologies not only aligns with sustainability goals but also supports economic growth through improved operational efficiencies.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025