Dec . 25, 2024 12:01 Back to list

Enhanced Durability and Oxidation Resistance for Superior Industrial Applications

Improved Oxidation Resistance Innovations and Suppliers in Advanced Materials

In today’s rapidly evolving industrial landscape, oxidation resistance has become a paramount concern for manufacturers and consumers alike. The degradation of materials due to oxidizing agents can lead to significant operational inefficiencies, safety hazards, and increased maintenance costs. Thus, the demand for improved oxidation resistance in various applications—ranging from aerospace and automotive to electronics and coatings—has surged.

Several suppliers around the globe specialize in providing advanced materials and coatings that enhance oxidation resistance. These innovations not only prolong the lifespan of materials but also improve overall performance in high-temperature and reactive environments.

Understanding Oxidation Resistance

Oxidation is a chemical reaction that occurs when a material reacts with oxygen, resulting in the formation of oxides that can deteriorate structural integrity. Metals, particularly those in high-performance applications, are especially susceptible to oxidation. For example, aluminum, while resistant to corrosion, can still oxidize under certain conditions, forming a layer of aluminum oxide that can affect its properties.

Improved oxidation resistance involves processes like alloying, the application of protective coatings, and the use of ceramics that inherently resist oxidation. Recent technological advancements have introduced new composite materials and surface treatments that significantly mitigate the effects of oxidation.

Key Innovations in Oxidation Resistant Materials

1. Advanced Coatings Suppliers now offer innovative coatings that provide a protective layer against oxidizing environments. High-temperature resistant coatings, such as those based on zirconia or aluminum oxide, are applied to extend the life of components in engines and turbines.

2. Ceramic Matrix Composites (CMCs) These materials combine the strength of ceramics with the toughness of metal. CMCs possess exceptional oxidation resistance, making them ideal for aerospace applications, particularly in jet engines, where they face extreme temperatures and oxidative conditions.

3. Nano-Coatings The development of nanotechnology has led to the creation of ultra-thin coatings that offer enhanced protection. These coatings not only resist oxidation but also improve thermal stability and wear resistance. Suppliers specializing in nanotechnology are emerging as key players in this space.

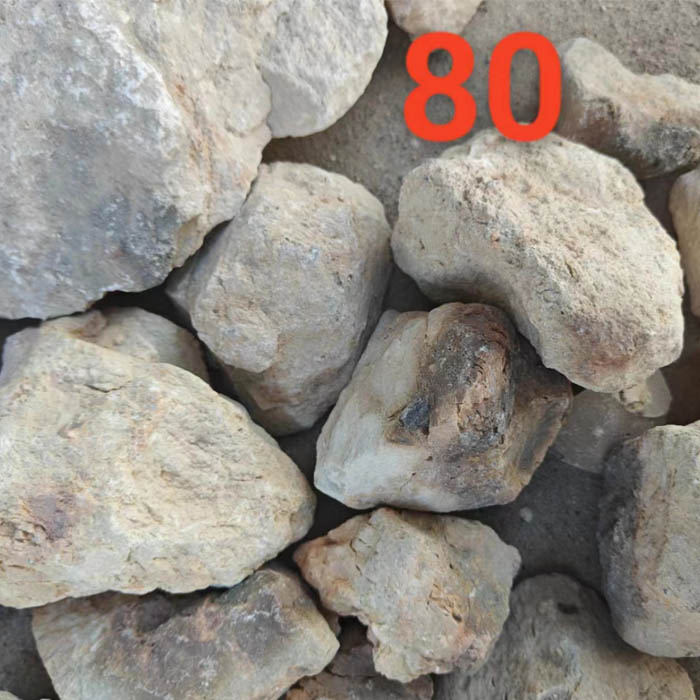

improved oxidation resistance suppliers

4. Alloy Development Research into new metal alloys has yielded formulations that inherently resist oxidation. For instance, nickel-based superalloys are widely used in jet engines due to their ability to withstand extreme environments while resisting oxidizing agents.

Choosing the Right Supplier

When selecting a supplier for improved oxidation resistance materials, several crucial factors should be considered

- Reputation and Expertise Opt for suppliers with a proven track record in providing high-performance materials. Look for certifications and industry endorsements.

- Customization Many applications require tailored solutions. Suppliers that offer customized formulations and coatings could provide significant advantages in performance.

- Research and Development Suppliers that invest in R&D are more likely to stay at the forefront of technological advancements. They can provide innovative solutions aligned with the latest industry trends.

- Sustainability Practices With increasing focus on sustainability, consider suppliers that prioritize eco-friendly processes and materials, aligning with global efforts towards reducing environmental impact.

Conclusion

The significance of improved oxidation resistance cannot be understated in today’s high-performance applications. As manufacturers continuously seek ways to enhance durability and performance, the role of specialized suppliers becomes increasingly vital. By leveraging advancements in materials science—ranging from advanced coatings and composites to innovative alloys—businesses can ensure they remain competitive, safe, and efficient.

In a world where materials are subjected to more challenging environments, it’s essential to partner with knowledgeable suppliers who can provide the necessary solutions to meet these demands. Investing in improved oxidation resistance technology not only adds value but also paves the way for greater innovation and sustainability in industrial practices. Thus, the pursuit of advanced oxidation resistance is not merely a trend but a crucial step towards the future of manufacturing and materials engineering.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025