Dec . 03, 2024 11:29 Back to list

inlex refractory materials suppliers

The Role of INLEX Refractory Materials Suppliers in Industry

In the realm of industrial materials, refractory substances hold a vital position due to their ability to withstand extreme temperatures and challenging environments. Among the many suppliers in this niche market, INLEX has established itself as a prominent name, catering to a variety of industries including metallurgy, glass, ceramics, and cement.

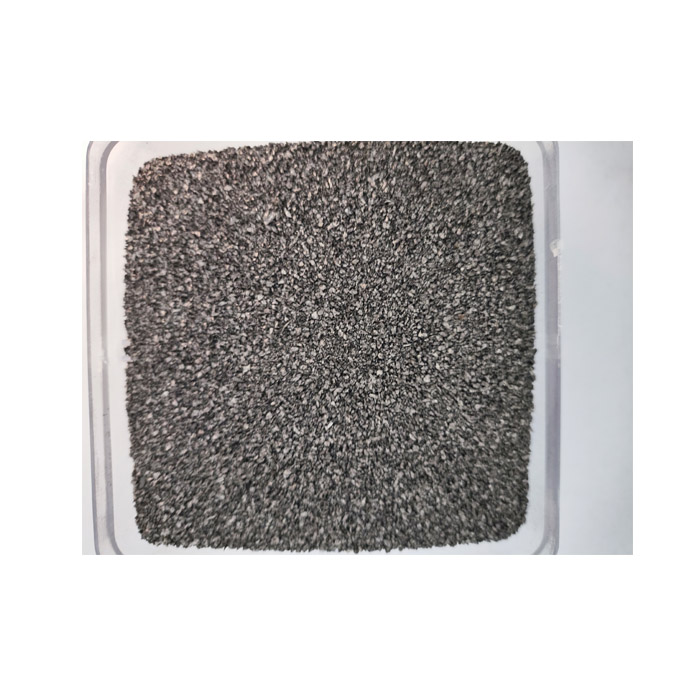

Refractory materials are designed to retain their strength and structural integrity when exposed to high temperatures, making them indispensable in several applications. INLEX refractory materials are known for their exceptional performance under thermal stress, offering solutions that enhance productivity and efficiency in manufacturing processes. The company supplies a diverse range of refractory products, including bricks, castables, and monolithic refractories, all engineered to meet specific operational conditions.

The Role of INLEX Refractory Materials Suppliers in Industry

The glass manufacturing industry also relies heavily on high-quality refractory materials. INLEX supplies refractories that can endure the intense thermal cycles involved in glass melting processes. These materials are designed to minimize thermal shock and improve heat retention, thereby enhancing energy efficiency. Additionally, INLEX’s expertise in custom solutions allows glass manufacturers to optimize their production processes, tailoring materials to their specific furnace designs and operational requirements.

inlex refractory materials suppliers

In the cement sector, refractories play a crucial role in rotary kilns, where the pyroprocessing of raw materials occurs at high temperatures. INLEX's advanced refractory solutions are engineered to handle the abrasive and corrosive nature of kiln environments, ensuring longevity and reducing the need for frequent repairs or replacements. This durability not only translates to cost savings for manufacturers but also supports sustainable production practices by extending the life of critical equipment.

Furthermore, INLEX emphasizes the importance of research and development, continually innovating their product lines to address the evolving needs of the market. By engaging in collaborations with clients, INLEX ensures that their offerings remain relevant and effective. This commitment to customer satisfaction and technological advancement has helped INLEX solidify its reputation as a trusted supplier in refractory materials.

The importance of sourcing quality refractory materials cannot be overstated, as the right products can significantly impact production efficiency and operational costs. INLEX stands out in the market not only for its diverse product range but also for its dedication to providing tailored solutions that meet the unique challenges faced by various industries. By combining expertise, quality materials, and innovative solutions, INLEX refractory materials suppliers are positioned to lead the way in helping industries achieve their operational goals while maintaining safety and sustainability standards.

In summary, the role of INLEX refractory materials suppliers is crucial in providing the necessary materials that support high-temperature industrial processes. With a focus on quality, innovation, and customer collaboration, INLEX continues to be a pivotal player in the refractory materials market, driving efficiency and performance across multiple sectors. As industries evolve and demand for advanced materials increases, INLEX is well-equipped to meet these challenges head-on, ensuring a resilient future for its clients.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025