Aug . 14, 2024 06:26 Back to list

Investigation of Dry Vibration Materials for Tundish Applications in China's Steel Industries

The Role of Dry Vibration Material in Tundish Applications in China

In the modern steelmaking industry, the demand for high-quality steel has necessitated advancements in various production processes, particularly in the secondary metallurgy phase. One key component in this phase is the tundish, a vessel that plays a crucial role in distributing molten steel to continuous casting machines. To enhance the efficiency and performance of tundish systems, the use of dry vibration materials has become increasingly prominent in China’s steel industry.

What is a Tundish and Its Importance?

A tundish serves as an intermediary vessel between the steel ladle and the continuous caster. It stabilizes the flow of molten steel, helps to remove impurities, and maintains thermal equilibrium. The design and operation of the tundish significantly affect the quality of the final steel product. For this reason, the materials used in constructing tundishes are of paramount importance to ensure their durability and functionality.

Dry Vibration Material Definition and Composition

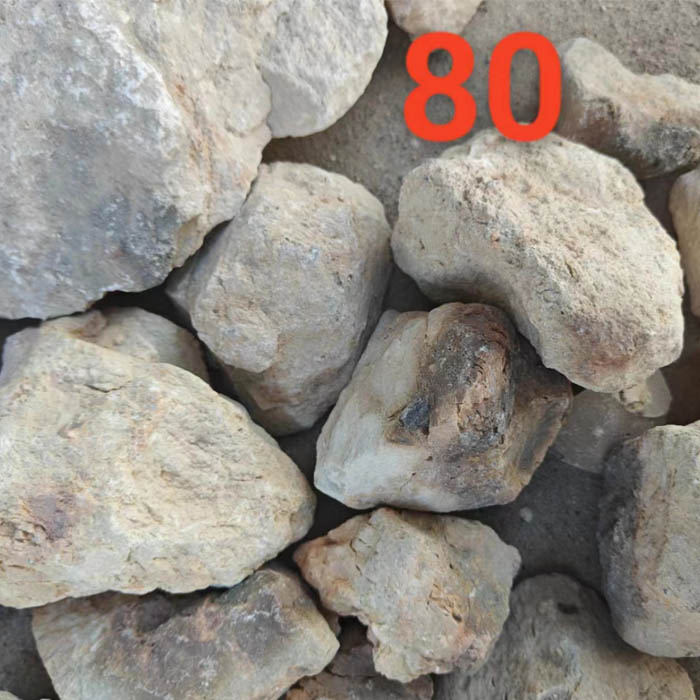

Dry vibration materials, also known as refractory materials, are specially formulated composites designed to withstand the high temperatures and harsh chemical environments of metallurgical processes. These materials are typically made from alumina, silica, and other refractory oxides which provide excellent thermal stability and resistance to thermal shock. In the context of tundishes, they are applied as a lining material to prevent the molten steel from reacting with the metal structure of the tundish, thus safeguarding the quality of the steel produced.

Benefits of Using Dry Vibration Material in Tundishes

1. Thermal Insulation Dry vibration materials offer superior thermal insulation, which is crucial in maintaining the temperature of molten steel. This property helps in reducing energy consumption and minimizes heat losses during the casting process.

china tundish dry vibration material

2. Reduced Reactions and Contamination These materials are designed to be inert, preventing unwanted chemical reactions between the molten steel and the tundish lining. This minimizes the risk of contamination, ensuring that the final steel product meets stringent quality standards.

3. Enhanced Flow Control The application of dry vibration materials aids in achieving better flow control within the tundish. By managing the flow of molten steel more effectively, manufacturers can reduce turbulence, which is vital for preventing inclusions and maintaining the structural integrity of the steel.

4. Durability and Longevity With the harsh environmental conditions inside a tundish, the longevity of the lining material is crucial. Dry vibration materials are specifically engineered to withstand extreme temperatures and mechanical stress, leading to reduced maintenance costs and extended service life.

The Implementation in China's Steel Industry

China, being the world's largest steel producer, has recognized the importance of advanced materials in improving steelmaking processes. The adoption of dry vibration materials in tundish operations is part of a broader strategy to enhance production efficiency and product quality. Steel manufacturers in China have increasingly invested in research and development to optimize these materials for local conditions, ensuring that they can withstand the unique challenges posed by the domestic market.

Moreover, the government’s push towards sustainable practices has encouraged steelmakers to explore innovative solutions like dry vibration materials, which can contribute to more energy-efficient processes and reduced emissions.

Conclusion

The integration of dry vibration materials into tundish operations represents a significant advancement in the steelmaking process in China. By enhancing thermal insulation, reducing contamination risks, improving flow control, and extending the lifespan of tundish linings, these materials play a vital role in producing high-quality steel efficiently. As the industry continues to evolve, the ongoing exploration and optimization of such innovative materials will be crucial in meeting both domestic and global steel demands.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025