Nov . 17, 2024 08:46 Back to list

iron powder msds factory

Iron Powder MSDS A Comprehensive Guide for Factories

Iron powder is commonly used in various industries, from manufacturing to metallurgy. It serves multiple purposes, including being a raw material for producing sintered parts, making ferrous powders for welding, and as an additive in chemical processes. However, handling iron powder necessitates a thorough understanding of its Material Safety Data Sheet (MSDS) to ensure safety and compliance in a factory setting.

Understanding the MSDS

An MSDS provides crucial information about the properties of a chemical substance, including its hazards, handling, storage, and emergency measures. For iron powder, the MSDS serves as a critical resource for safety management within factories. It categorizes the data into several sections, each detailing specific safety instructions and potential hazards associated with iron powder.

Physical and Chemical Properties

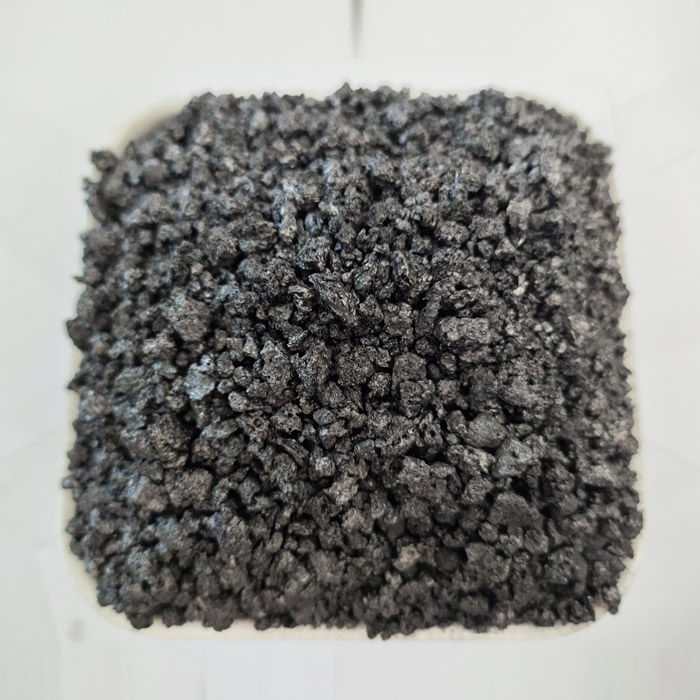

Iron powder typically appears as a fine, grayish-black powder and can vary in composition based on its manufacturing process. It is important to note its physical properties, such as melting point, boiling point, density, and solubility. These factors influence how iron powder behaves under different conditions, particularly when exposed to moisture, which can lead to oxidation and the formation of iron oxide (rust).

Hazards Identification

Iron powder is generally considered to have low toxicity, but it poses certain hazards, especially in the form of dust. When finely divided, iron powder can be a fire and explosion hazard if not handled correctly. Dust clouds can ignite or explode in the presence of an ignition source. Factories must implement measures to minimize dust generation, including proper ventilation systems and dust collection units.

Safe Handling and Storage

iron powder msds factory

To ensure safety in the workplace, several guidelines should be adhered to when handling iron powder. This includes using personal protective equipment (PPE) such as gloves, safety glasses, and respiratory protection to prevent inhalation of dust. When storing iron powder, it should be kept in a cool, dry, well-ventilated area away from incompatible substances such as oxidizers. Containers should be hermetically sealed to prevent moisture absorption, which can compromise the quality of the powder.

Emergency Measures

In case of a spill or accidental exposure, the MSDS outlines necessary emergency procedures. Safety personnel should be trained to respond appropriately to incidents involving iron powder. For spills, avoid using water, as it may create a slippery surface and exacerbate the situation. Instead, sweep up the powder carefully to avoid generating dust and place it in a suitable waste container for disposal.

Environmental Considerations

Iron powder can pose environmental concerns if released in large quantities, leading to soil and water contamination. Factories should have protocols in place for managing waste and ensuring that any discharge complies with local environmental regulations. It is advisable to recycle iron powder whenever possible to reduce waste and environmental footprint.

Conclusion

In conclusion, understanding the MSDS for iron powder is essential for factory operations involving this material. By familiarizing themselves with the properties, hazards, and safety measures outlined in the MSDS, factory personnel can significantly minimize risks. Regular training and adherence to safety protocols will aid in creating a safer working environment while maximizing the benefits of iron powder as a valuable industrial material. Ensuring proper handling, storage, and emergency preparedness not only protects the workforce but also contributes to a sustainable manufacturing process.

Through knowledgeable practices and a commitment to safety, factories can safely utilize iron powder, harnessing its potential while safeguarding their employees and the environment.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025