Dec . 07, 2024 14:58 Back to list

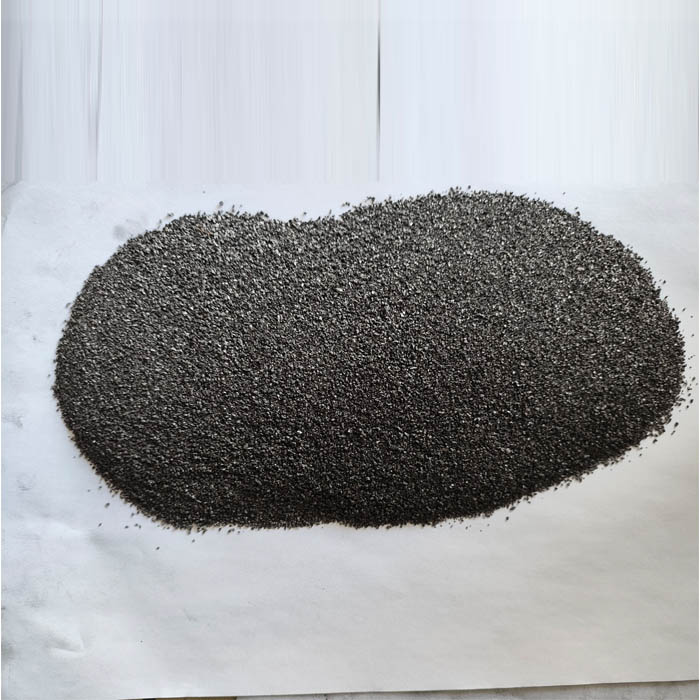

liquid graphite lubricant factories

Liquid Graphite Lubricants The Future of Industrial Lubrication

In the ever-evolving landscape of industrial lubricants, liquid graphite lubricants have emerged as a revolutionary solution. With their unique properties and versatile applications, liquid graphite lubricants are gaining significant traction across various industries. This article explores the benefits, applications, and future potential of these innovative lubricants, emphasizing the role of factories in their production.

Understanding Liquid Graphite Lubricants

Liquid graphite lubricants are a blend of graphite particles suspended in a liquid carrier, often oil-based or water-based. Graphite, a natural form of carbon, has excellent lubrication properties due to its layered structure. This unique composition allows the layers to slide over one another with minimal resistance, making liquid graphite an effective lubricant for reducing friction and wear in mechanical systems.

One of the most remarkable characteristics of liquid graphite is its ability to withstand extreme temperatures. It can function effectively in environments ranging from cryogenic temperatures to those exceeding 1000 degrees Celsius. This high-temperature stability makes liquid graphite lubricants ideal for industries such as automotive, aerospace, and manufacturing, where equipment operates under intense heat.

Benefits of Liquid Graphite Lubricants

1. Enhanced Performance Liquid graphite lubricants significantly reduce friction, minimizing wear and tear on machinery. This results in improved performance, extended equipment life, and reduced maintenance costs.

2. Environmentally Friendly Unlike many conventional lubricants, which may contain harmful additives and chemicals, liquid graphite lubricants can be more sustainable. Graphite is a natural resource, and the formulations can often be designed to reduce environmental impact.

3. Wide Range of Applications From heavy machinery to small-scale automotive parts, liquid graphite lubricants are applicable in various industries. They provide superior lubrication in conditions where traditional lubricants may fail, such as in high-load or extreme-temperature environments.

4. Non-Corrosive Liquid graphite is inherently non-corrosive, which is crucial for industries that deal with sensitive materials and components. By using liquid graphite lubricants, factories can reduce the risk of corrosion-related damages.

liquid graphite lubricant factories

Role of Factories in Liquid Graphite Lubricant Production

The production of liquid graphite lubricants involves advanced manufacturing processes, and factories play a vital role in ensuring the quality and consistency of these products. Factories specializing in liquid graphite lubricants are equipped with state-of-the-art technology to create high-performance formulations that meet the specific needs of various industries.

1. Quality Control Factories implement stringent quality control measures to ensure that every batch of lubricant meets the required specifications. This includes testing for viscosity, stability, and performance under different conditions.

2. Research and Development Continuous innovation is crucial in the lubricant industry. Factories invest in research and development to formulate new and improved liquid graphite lubricants that can address emerging challenges in lubrication technology.

3. Customization Different industries have unique lubrication needs. Factories that produce liquid graphite lubricants often offer customization options, allowing clients to specify formulations that best suit their applications.

4. Sustainability Initiatives Many factories are now focusing on sustainable practices, from sourcing raw materials to eco-friendly packaging. By prioritizing sustainability, these factories contribute to a greener future while meeting the ever-increasing demand for environmentally friendly products.

Future Trends in Liquid Graphite Lubricants

As industries continue to seek high-performance, environmentally friendly lubricant solutions, the demand for liquid graphite lubricants is expected to grow. Emerging technologies and applications, such as electric vehicles and renewable energy systems, will likely drive further innovation in this field.

Additionally, as awareness of the importance of sustainability increases, liquid graphite lubricants may play a pivotal role in reducing the carbon footprint of various industrial processes. Factories that can adapt to these trends and continue to innovate will be well-positioned to lead in the liquid graphite lubricant market.

In conclusion, liquid graphite lubricants represent a promising frontier in lubrication technology. With their unparalleled performance, sustainability, and adaptability across diverse applications, they are set to revolutionize the industry. The role of factories in producing high-quality liquid graphite lubricants cannot be overstated, as they are crucial for driving innovation and ensuring consistency in this rapidly evolving market.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025